Marc Spagnuolo's Blog, page 83

December 13, 2014

Giving Back Through Woodworking – Tis’ The Season

The holiday season reminds us to give back and help others in need, but Jeff and Linda Morton at Feisty Dog Woodcrafts have made it a point to give back all year round – to our furry friends. With an eye for detail and craftsmanship, they produce excellent work (my favorite is the Greene and Greene inspired pet feeder), and they also support animal rescue while doing it!

The holiday season reminds us to give back and help others in need, but Jeff and Linda Morton at Feisty Dog Woodcrafts have made it a point to give back all year round – to our furry friends. With an eye for detail and craftsmanship, they produce excellent work (my favorite is the Greene and Greene inspired pet feeder), and they also support animal rescue while doing it!

I was excited to be able to interview Jeff Morton to get the inside scoop on Feisty Dog Woodcrafts. In the interview, Jeff shared not only his background in woodworking and how Feisty Dog came to be, plus you’ll gain some really great insight into the business of woodworking. Enjoy!

How did you get started woodworking?

I’ve been around woodworking from a early age. My brother-in-law was a product design engineer at Black & Decker (was involved with the first VS drill). Both he and my dad were fairly active. BIL built furniture and cabinets and dad built more utilitarian things. I learned a lot about workshop safety, how to approach a project and how to enjoy the process. Woodworking is my “mental floss” to escape the work/life rat race. I enjoy the tactile nature of the craft and the personal satisfaction I receive when a design comes together and delights the customer.

How long have you been selling your woodcrafts?

We’re starting our second year of actively marketing our products. We did ad-hoc projects for friends/family before that, but didn’t actively peruse the venture until fall 2013.

How has selling products affected your woodworking? Sadly, quite a bit. The ability to wander into the shop and make something for fun isn’t in the plan. It’s now more on a production schedule: mill work -> assembly -> finishing. Off times, we’re working on promotion, answering communications, coming up with new ideas, etc or acquiring project materials. It’s a little easier to not have a “real job,” to work around, but then the need to produce and sell scratches off the luster pretty soon. a PT job brings some money in while allowing time for the business, but…

Sadly, quite a bit. The ability to wander into the shop and make something for fun isn’t in the plan. It’s now more on a production schedule: mill work -> assembly -> finishing. Off times, we’re working on promotion, answering communications, coming up with new ideas, etc or acquiring project materials. It’s a little easier to not have a “real job,” to work around, but then the need to produce and sell scratches off the luster pretty soon. a PT job brings some money in while allowing time for the business, but…

Needing to make things that sell impulsively eliminates the ability to make enjoyable things that aren’t as directly sell able. I want to build a Krenovian-inspired case as well as a “Greene & Greene light” project. Hopefully I will be able to do after the holiday rush. Health issues have suspended shows for the rest of 2014, but we plan to be on the show circuit in late Q1/15. I also have a commission project in Q1/15 for some built in Stickley-influenced bookcases in a newly-constructed home’s rec room, but those jobs are few and far between.

How did the concept of Feisty Dog Woodcraft come about? My wife Linda and I have been involved in animal rescues for awhile, We’ve adopted three amazing dogs, two of them, Hunter (who is a Mountain Feist dog, a combination of a rat terrier, greyhound and Labrador retriever that has been bred for hunting squirrels since Abe Lincoln’s time – and the basis of our business name) and Daphne (a dachshund/corgi mix), are our “Executive Staff.”

My wife Linda and I have been involved in animal rescues for awhile, We’ve adopted three amazing dogs, two of them, Hunter (who is a Mountain Feist dog, a combination of a rat terrier, greyhound and Labrador retriever that has been bred for hunting squirrels since Abe Lincoln’s time – and the basis of our business name) and Daphne (a dachshund/corgi mix), are our “Executive Staff.”

Unfortunately, Trixie,who survived a horrific fire at a dog pound in southern Illinois in 11/2007, had a terminal illness and left us in 2011. Her spirit remains with us. We have volunteered for Fur Keeps Animal Rescue in Barrington Hills, IL and perform pre-adoption site visits and whatever else they need to further their cause.

Woodcrafts by Feisty Dog was created initially as a way for me to avoid becoming a WalMart greeter in my “golden years.” Based on the marketplace, I knew we could create and market quality handcrafted products for two and four legged friends – with some percentage of earnings donated to animal rescues – another way for us to give back and help. It could develop and grow to the point when we wander off into retirement, we could take the business with us and keep going.

To increase awareness and contribution, we become affiliated with animal rescues, who encourages their staff, volunteers and clients purchase merchandise from us – with the net profits going directly to their rescue. We also provide them at least $150 of free merchandise annually for their fundraising activities. To date, we’ve donated nearly $1,500 in merchandise in 2014 to wonderful groups like PAWS Chicago, Save-A-Pet, etc. as well as our local Fire Department for their annual fundraiser. When someone purchases from us, we ask them if they have a favorite animal rescue. If they do, it is noted on the receipt as well as our books. We send check quarterly, and always round up to make it more beneficial. If the customer doesn’t have a specific rescue,we divide the funds among affiliated rescues.

Unfortunately, economic realities in 2014 “encouraged” us to ramp up the business. My wife’s job was eliminated in February. Fortunately she found a wonderful job with a great company in July – which she enjoys, and provided us needed healthcare benefits. My job was eliminated in March. However, I recently was offered a part time job and might possibly have other options in the near future. But the situation gave us an opportunity to really focus on the business, out of necessity.

What advice do you have for someone who is just starting out or thinking about starting a woodworking business/side business?  First: STOP, take a breath and really think it through.Do your homework – visit local shows and do a little “intel work” – see what’s out there – primarily what’s missing and what’s selling. Check the internet sales sites and do the same “intel work.” This was easy for me, since I’ve spent the last 34 yrs in marketing research with direct involvement with successful products like Gerber Graduates, America’s Cut pork chops, etc. and revolutionizing the market information/segmentation/analysis process in the home building industry (I also predicted the housing bubble 14 mos in advance, but that’s another story).

First: STOP, take a breath and really think it through.Do your homework – visit local shows and do a little “intel work” – see what’s out there – primarily what’s missing and what’s selling. Check the internet sales sites and do the same “intel work.” This was easy for me, since I’ve spent the last 34 yrs in marketing research with direct involvement with successful products like Gerber Graduates, America’s Cut pork chops, etc. and revolutionizing the market information/segmentation/analysis process in the home building industry (I also predicted the housing bubble 14 mos in advance, but that’s another story).

Once you’ve done your market analysis, decide IF you have something that is viable, and make sure you can build it right ALL the time – potentially in mass quantities. To make money, you MUST streamline the process without cutting quality for time/cost savings – which pay you back. Go with your strengths – especially if they are unique/different to what’s offered. Don’t try to offer a bunch of things that you aren’t confident in the quality of design and build. This is definitely a time when less is more. Promoting your BEST efforts – even if it’s one product – is much better than having a bunch of so-so stuff on the table.

Establish a consistent BRAND identity and stick with it! all of our are promotional materials – including show banner, booth signage and embroidered polo shirts worn at shows are based, literally on our BRANDing iron logo. (photo attached) I believe that a consistent brand message sets you apart from other vendors – that you have it together and MEAN business. I also think that it might convey an “expensive business” image to those who are motivated by bargains/deals, but if they aren’t your targeted market segment or don’t even stop to see your offerings, who cares!

Start SMALL and grow s-l-o-w. Go with a basic website at first if you have to with a small, finite number of products you can promote. PayPal can be your friend, because you can take orders via emails and process payments through PP. E-commerce vendors can be a slippery slope to an eternal abyss. Let the business grow to the point where you NEED the larger, fancier site and third-party e-commerce processing.

Pick your shows carefully. If you have high volume/low price products, craft shows, flea markets, etc might work for you. Otherwise, target the juried art shows and up-scaled craft shows. They cost more to participate and require a higher-quality offering, but the ROI is worth the time/cost/trouble, because patrons are more likely to appreciate (read: BUY) your products!

Where can people find out more about you and Feisty Dog Woodcraft?

We’re on Twitter as @feistydogww. You can find us on Facebook at facebook.com/FeistyDogWoodcrafts. Our web store is at feistydogww.com and our Etsy store is at etsy.com/shop/FeistyDogWoodcrafts.

I hope that everyone enjoyed learning about Feisty Dog Woodcrafts. You can see more of their work and find out more about the support they provide to animal shelter organizations. Big thank you to Jeff for taking the time to do this interview and share some great tips for anyone interested in selling their work.

December 10, 2014

John’s Basement Workshop

From: John Gravatt (North Liberty, IA)

Shop Type: Basements

Shop Size: 250-499

My basement shop is small, but gets the job done. It started out as a 13 x 12 room, but I quickly gobbled up the 11 x 10 room next to it. Unfortunately, I am now landlocked and can’t expand without tearing out some of the finished basement. Needless to say, my wife does not approve.

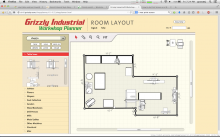

I have spent literally hours trying to design a small space layout using the Grizzly shop planner. I think I came up with 70+ variations before I settled with the current one. Apparently, I am addicted to shop planning.

Most of my tools I had to buy new, because Craigslist just doesn’t have much in my area. I watched the site for months before I gave in and bought a new table saw. Then other new power tools starting showing up. I think I ended up with 2 good finds on Craigslist thus far, my Jet dust collector and Jet mortiser.

I hope to tear down and build some new workbenches in the future. I slapped these together using construction lumber, just to get started. Unfortunately, it hasn’t been a priority since and my project backlog keeps growing with no end in sight. A good problem to have I suppose!

December 9, 2014

236 – Arts & Crafts Kitchen Helper

One of Nicole’s favorite things to do with our son is cook. At this stage, it’s mostly measuring ingredients and stirring but we’ll soon move on to cutting vegetables and other fun tasks. And while many adults look at cooking as a chore, kids see it a compelling and fun way to be useful. Not only that, but our son is a very picky eater. We find that making him a part of the cooking process makes it much easier for him to try new foods.

So clearly, we embrace his presence in the kitchen. To that end, he usually uses either a step-stool or a chair to do his work. Unfortunately, the stool is too short, the chair is too tall, and neither of them proves to be conducive to longer cooking sessions. So I set out to design a kids step-stool that includes features like safety elements, height adjustability, custom-sizing for kitchen countertops, and a nice wide platform. I looked around at some of the commercial designs for inspiration and really didn’t like what I saw. Most of them were fairly unattractive plywood structures that looked more at home in a Gymboree than in a kitchen. Since we have to look at this thing every day, I decided it must also be attractive. So a stylish appearance was the final feature I included. The end result is the Arts & Crafts Style Kitchen Helper.

The Materials

Be sure to download the plans for a full list of materials and hardware. I used 4/4 cherry for everything but you certainly could use 3/4″ plywood if that better suits your needs. The joints are constructed with the Festool Domino and the knockdown hardware consists of 1/4-20 threaded inserts and 1/4-20 bolts. As an alternative to Domino joints, consider the humble classic dowel!

Be sure to download the plans for a full list of materials and hardware. I used 4/4 cherry for everything but you certainly could use 3/4″ plywood if that better suits your needs. The joints are constructed with the Festool Domino and the knockdown hardware consists of 1/4-20 threaded inserts and 1/4-20 bolts. As an alternative to Domino joints, consider the humble classic dowel!

The Finish

When it comes to a project like this one, damage isn’t a question of “if” it’s a question of “when.” So I opted for a fairly light-duty finish that’s easily repairable, much like I might use on a workbench in the shop. The finish is an oil/varnish blend. In the video, you’ll see I used Watco Teak Oil (an outdoor formulation) but only because I wanted to get rid of the can before it went bad.

When it comes to a project like this one, damage isn’t a question of “if” it’s a question of “when.” So I opted for a fairly light-duty finish that’s easily repairable, much like I might use on a workbench in the shop. The finish is an oil/varnish blend. In the video, you’ll see I used Watco Teak Oil (an outdoor formulation) but only because I wanted to get rid of the can before it went bad.

In Use

Since it’s the holiday season, the Kitchen Helper has seen a lot of use already. It does exactly what it’s supposed to do, giving our son a comfortable place to hang out while actively participating in kitchen activities. I should note that he’s actually more attentive and has more patience while he’s using the Kitchen Helper. Something about it makes his experience more of a learning “event” rather than simply helping mom or dad. He still uses a regular step stool to get water and do other small tasks, but when it’s time to cook with mom he’s all about his Kitchen Helper.

Now if you don’t get it, you’re not alone. A common question I received when posting pictures of this project was, “I don’t understand how it works!” If that’s the case, it’s only because you’re thinking like an adult. When a kid sees this thing, they know exactly how it works, how to get into it, and how to get out of it. You’ll even see my son using it for the first time at the end of this video and no one needed to give him any direction at all.

If you decide to build one of these bad boys, send us a pic with your kid using it. We’d love to share it with the world!

Gallery

December 8, 2014

Solar Power for the Workshop?

Image by Kreuzschnabel/Wikimedia Commons, License: artlibre

Every time I discuss electrical power as it relates to the shop someone will inevitably bring up the question of solar energy. After all, I’m in the “Valley of the Sun” and if anyone should be able to harness the awesome power of that big ball of fire in the sky it should be Phoenicians with our 296 days of sunshine per year! Well, you might be surprised to know that I actually do have solar panels and I thought it would be helpful to share my story and experience. This is not meant to be a guide to solar energy and I’m not really prepared (or qualified) to give much advice on the topic. When you dig into the world of alternative energy you’ll quickly find out that there’s a lot of ever-changing local laws, regulations, and red tape that will dictate what you can and can’t do so be sure to do your research. If anything, my hope is that this blog post encourages you to look into your options with realistic expectations.Our Setup

When we decided to go solar, the company we hired did an audit of our electrical usage over the last few years. Their goal was to correctly match our power needs with our future power production. They also made sure our house could accommodate the number of panels we needed and of course the roof had to be able to support the additional weight. In addition to the panels, we had to select a location for the power converter dealie-wackers. In our case, these were three large wall-mounted devices that live in our garage. Some people put them outside but it’s quite an eyesore. Something to keep in mind is that these things make quite a bit of noise during the day. As they process the energy, they make a rhythmic clicking sound that can easily be heard in the guest bedroom on the other side of the garage wall.

To Buy or Lease?

While on the surface this might seem like a big part of the decision, but for us it was a no-brainer. We found the purchase price to be prohibitively expensive (approximately $35,000) so we went for the lease program. The lease locks us in at a monthly price of $220 for 20 years and ensures the system will continue to be operational for the duration of that period. If we sell the house, the new owner simply takes over the lease. And after about six years, we’ll have the option to purchase again at the appropriate reduced cost. I doubt we’ll take that option.

How Does it Work?

It’s not as simple as you might think. I was originally under the impression that solar panels would pull us “off the grid” and we would be self-sufficient but that’s not how it works. The solar panels produce energy and that energy is sent back to the electric company. They keep track of our production as it offsets our usage. So we still pull power from the electric company just like we always have, but the power we send to the electric company cancels out the power we draw. If we produce more than we consume, we will get paid for the unused energy. The value of that payment is something that seems to be in flux and it was recently lowered.

The Financials

Our electric bill used to average $350 and increased each year. We use dramatically more energy in the summer due to the constant running of air conditioners so we rely on a level-pay program to keep our bill predictable each month. So now that our solar panels are compensating for our energy use, our electric bill amounts to about $20/month. Just by virtue of being connected to the grid, there will always be small associated fees that need to be paid. Our total monthly payment is:

$20 (electric company) + $220 (lease fee) = $240 Total

Savings: At least $110/month

Because our panels were set up to handle our worst case usage scenario, we won’t likely see a change in our monthly bill for a very long time and we generally over-produce each month. Furthermore, this setup insulates us from energy price increases as the lionshare of our bill is going to our lease and not the electric company. Of course there may be unforeseen circumstances that cause us to regret our decision to go this route, but now that we are two years into this arrangement I have to say we are extremely happy with it. Below you can see a graphic showing our power production for the last 14 months with some cool statistics about what that amount of energy equates to.

Don’t Take My Word For It!

Do your research. As I mentioned before, the laws are ever-changing and the system (government and big utilities) seems to be set up to discourage folks from incorporating alternative energy sources into their homes. For example, I heard recently that they are considering a special surcharge for folks who have solar panels and efforts are already underway in Oklahoma. I’ll refrain from getting too political here but let’s just say it can be incredibly frustrating for people who are just trying to “do the right thing.”

If you already have solar, I’d love to hear about your experiences. And if the laws are different in your area, I’d love to hear about that too. Let’s compare notes!

Poll: Batching Out

‘Tis the season… When we build projects for all of the relatives on our gift list.

Sure, there have been years when Aunt Mabel wants a cutting board, mom wants a picture frame, your cousin Vinny wants a cigar humidor, and you built individual projects for each.

Sure, there have been years when Aunt Mabel wants a cutting board, mom wants a picture frame, your cousin Vinny wants a cigar humidor, and you built individual projects for each.

But it’s so much more efficient to build one kind of project for everyone. This way, everyone on the list gets the same item built in steps. You can cut all the pieces with the table saw fence set to the right width, cut mortises with the router bits set to the right depth, etc. Essentially, it becomes production work.

So this week, tell us if you’ve built multiple copies of a particular project and how many you’ve batched out!

How many copies of one project have you ever built at one time?

235 – Woodworkers Fighting Cancer 2014 Wrap-Up

This year’s Woodworkers Fighting Cancer was an absolutely record-breaker. This year we had 340 Toy Chest submissions and a total donation amount of $15,648, all of which goes toward cancer research at the Cancer Research Institute.

We’d like to thank the sponsors, the individual donors, and of course all of the folks who took the time to build along with us. If you’d like to take a look at all of the submissions, you can do so here.

As always, you guys make us proud to be part of this incredible woodworking community!

December 5, 2014

TWW Live 07 – Holiday Bash!

Join us for our yearly holiday celebration. We’ve got cider, powdered donut balls, and free woodworking stuff! A great way to spend a Friday night!

December 4, 2014

Woodworkers Fighting Cancer Toy Chests

By: Escondido High School Advanced Wood Shop (Escondido, CA)

Project Type: Boxes, Chests, Kids Projects

My name is Nathan Boelhauf and I am a wood shop teacher in Southern California. In an effort to get my students involved in giving back to the community, we came up with the idea to make 18 of the toy boxes for the Woodworkers Fighting Cancer charity. We plan to fill each chest with books and toys and deliver them to the 18 elementary schools in our city. We have asked the local principals to select a student or family

in need to receive the Toy Chests.

When my students heard about this opportunity to build something and raise money for cancer they jumped on it. This year we lost a beloved staff member to cancer and several other staff members are currently fighting cancer.

Unfortunately, we were only able to produce 7 chests before we had to take a week off for Thanksgiving. I had a dedicated group of students staying late into the night to build the toy chests in the 5 days we had to build them. But we are set to complete 11 more before the winter break.

December 3, 2014

TWW Live Holiday Bash!

Join us this Friday for a special late edition of TWW Live! Every year we do a holiday giveaway bash and this year we decided to combine it with our monthly TWW Live show. The show will take place on Friday at 8pm Eastern/5pm Pacific on the Live Page. We’ll break from our typical format to do an entire show full of giveaways including DVDs, books, Guild subscriptions, a tool or two, and TWW Gear! It will be a festive woodworking celebration!

If you’d like to enter for a chance to win something please use the form below. Winners and prizes will be announced during the live show!

The form below could be a bit confusing so here are specific instructions:

– Log in using either Facebook or your Email.

– You will see two options: “Enter Your Email” and “Enter Your Name & Address”. You need to do BOTH of these in order to be entered.

This event is always a good time and we hope to see you there!

November 30, 2014

Poll: Buying Lumber Online

The plans have been drawn up. The tools have been sharpened. The shop has been prepped. The only thing you need to do is buy wood to build that special project.

Now, where will you get the wood from?

In years past, there was little choice. All lumber was bought locally at a hardwood supplier, construction yard, or at a local sawmill.

Today, the Internet offers a tremendous variety of sources to choose from. Whether you look at an online auction such as eBay or find an online provider such as Bell Forest Products, your purchasing options are seemingly limitless.

Today, the Internet offers a tremendous variety of sources to choose from. Whether you look at an online auction such as eBay or find an online provider such as Bell Forest Products, your purchasing options are seemingly limitless.

So this week, let us know if you have ever taken the plunge and bought your lumber online.