Vivek Sood's Blog, page 45

February 1, 2016

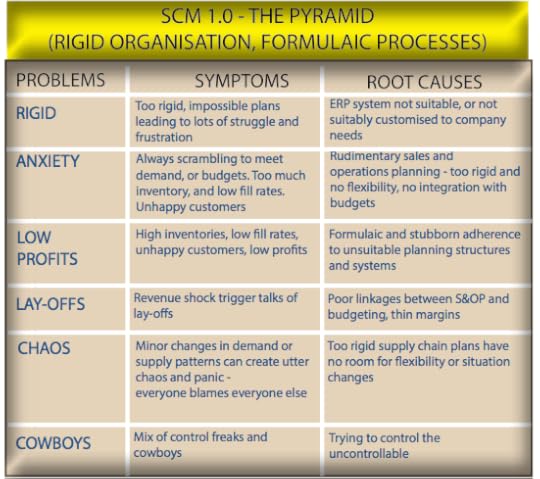

ERP Unraveled: Why Your Business Might Suffer From Inadequate Planning

To combat the symptoms of departmental silos many organizations implement a very rigid Enterprise Resource Planning (ERP) system. This helps run their internal processes and coordinates inter-departmental communication. By their nature, these systems are very formulaic and prescriptive with a one-size fits all approach to planning. Now a different bunch of problems start surfacing as a result. If you’ve ever wondered why you see so much chaos, anxiety, blame game, and other such dysfunctional behaviors in businesses, this is the key reason.

The Effects of ERP

In my newest book, Unchain Your Corporation, I explore the reasons for this perceived chaos in greater detail. Feel free to visit unchainyourcorporation.com for more information.

The post ERP Unraveled: Why Your Business Might Suffer From Inadequate Planning appeared first on Global Supply Chain Group | Management And Strategy Consultants.

January 31, 2016

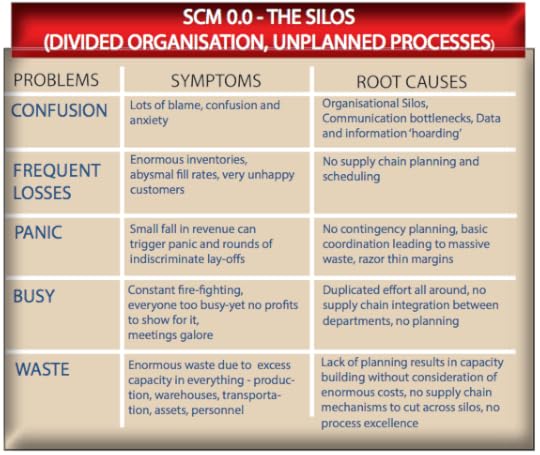

Departmental Silos: The Achilles Heel of Your Company

Businesses are gradually being chained by a number of forces so ubiquitous and accepted by all of us, that we fail to notice their impact on businesses, economies, and people.

Today, most organizations become veritable bureaucracies as they grow bigger. Every person sits inside his/her own department and is very careful about making sure that their department doesn’t carry the blame if there is a mix-up. Covering the tracks becomes the norm. The resulting departmental silos create stilted communication.

Problems With Silos

The post Departmental Silos: The Achilles Heel of Your Company appeared first on Global Supply Chain Group | Management And Strategy Consultants.

January 28, 2016

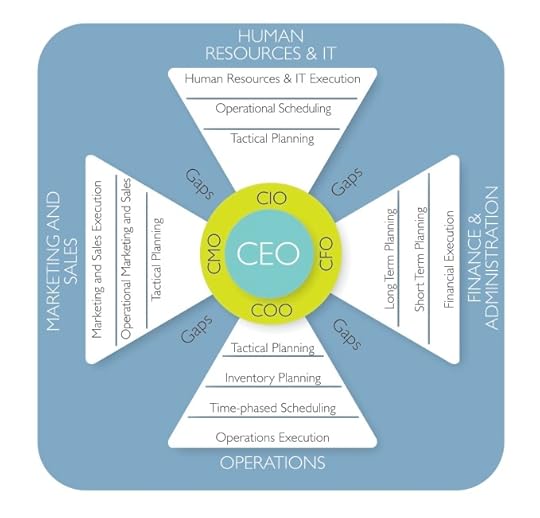

Mind The Gap

Why do companies achieve far worse performance than what could be feasible with their superior hiring and training capabilities?

It appears as if there are some invisible chains that are constantly pulling these companies back all the time. Something significant yet intangible is acting as a brake that inhibits the functionality of the business, causing each component to operate at less than its full value. Everyone is doing their best under the circumstances and their personal and departmental priorities, yet there is always a gap in the inter-functional integration.

Interfuctional Collaboration

What is this gap, and how does it happen? How does this gap harm you and your company?

In my newest book, Unchain Your Corporation, I explore these questions in greater detail.

The post Mind The Gap appeared first on Global Supply Chain Group | Management And Strategy Consultants.

September 22, 2015

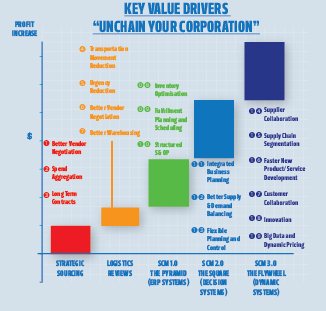

Optimising What? Why Business Transformations Fail?

Optimisation has always been a hot topic for strategists and business transformations executives. Now, as the mantle for leading corporations is moving from strategists to the integrationists and supply chain leaders – optimisation is hotter than ever before.

When discussing business transformations, in my workshops, presentations and speeches, in particular I enjoy the audience interaction and questions. It does bring out many critical points that may lie embedded inside people’s minds as assumptions. Everyone is talking about optimisation at these events today. The assumption being, there is just one kind of optimisation.

The example I gave in a recent workshop, and in my speech at the Quintiq World Tour, to highlight various levels of optimisation was that when I was a second officer, as a navigation officer of the ship I was in charge of optimisation of the route from a series of loading ports to a series of discharge ports. In most cases this job was relatively simple (if you knew elementary chartwork and navigation). When I grew in rank to the chief officer, I was optimising the cargo flow as well to make sure that the loading operations, discharging operations and stowage were carried out optimally to minimise the time taken and maximise the cargo throughput within that time. As a master the job expanded to include optimising the cost of the voyage by minimising the fuel consumption (about 33% of the operational cost) and maximising the charterers’ results.

As is self-evident, multiple layers of optimisation are added on top, as the complexity and responsibility grows. From costs of one ship, you can increase it to the cost of the entire fleet, and then add on costs of the land freight to create an end-to-end freight picture, and further add on cost of warehousing and storage to optimise the logistics costs. Forther on, you can optimise the entire distribution network by relocating your distribution centres, and then start talking about optimising your inventories and move into the realms of supply chain optimisation.

Taking it further, you can include the procurement – order placement, receipt and putaways, demand forecasting and shaping, supply planning – production and fulfilment to essentially optimise the basic supply chain.

But now, leading companies are not only optimising basic supply chain, they are also moving into collaborating with finance to optimise budgeting. Many are also collaborating with their suppliers and customers to optimise product development, research and marketing. Yield management and customer behavioural analysis helps optimise the price at the point of sale and targeted coupons and offers. Combining revenue optimisation with the cost optimisation can lead to profit optimisation which can move beyond dynamic pricing to supply chain segmentation of one.

The key point of this article would have been clear by now – everyone talks about optimisation. What matters more is WHAT ARE YOU OPTIMISING, AND HOW WELL ARE YOU DOING IT? I have already written another article to cover the second part of this question.

The post Optimising What? Why Business Transformations Fail? appeared first on Global Supply Chain Group | Management And Strategy Consultants.

BIG PICTURE vs REAL PICTURE – WHAT IS REQUIRED FOR BUSINESS TRANSFORMATION?

Glo bal shipping is a very cut-throat business where you can make a lot of money just by buying and selling ships at the right time. So ships in operation are sold quite regularly.

bal shipping is a very cut-throat business where you can make a lot of money just by buying and selling ships at the right time. So ships in operation are sold quite regularly.

When I was in shipping – there were two kind of buyers who visited the ships to inspect them prior to purchasing them.

The first kind were mainly the big picture guys who would come in and inspect all that voluminous paperwork, look at the ship’s bridge, paintwork and general layout of the ship and then spend a lot of time with the captain, chief engineer and chief officer in the hope that they would pick up nuggets of valuable information that could be reported back to the the prospective buyers. These people essentially relied less on their technical expertise in shipping, and more on their knowledge of human psychology to try and trip up the ship staff in revealing some defects or problems that could be used as leverage to lower the price of the ship during negotiations. Their reports looked very shiny and well formatted, and these were preferred by some prospective buyers who needed such reports – e.g. many banks and trading houses (mainly non-shipping entities).

The second kind would don the boiler suit the moment they boarded the ship and spend a lot of the time going into each and every double bottom tank, engine room bilge, forecastle store room and all the least visited parts of the ships. Frequently they would discover things that even the ships’ staff did not fully know. These people essentially relied on their shipping knowledge to assess the real condition of the vessel to report back to the prospective buyers a very thorough report of the ship, and points to watch out for if they bought the ship. They could also easily help the buyers work out a ship up-gradation program that was cost and time effective. Many of these folks wrote simple, factual reports that were not too professionally produced – but they were preferred by the shipping entities who were “in the game”.

Occasionally we would see someone who combined these two skill-sets marvelously and was a master at the game.

When, post MBA, I moved to management consulting with a top-tier global firm I noticed many characteristics of the first kind. I will not go too much into the detail but many readers can likely fill in the picture for themselves, and it is also quite well known what kind of clients prefer these “brand names”.

I also saw there were many folks out there who were more like the second kind. Again, the readers would have likely encountered this type of management consultants too.

In nearly 20 years of management consulting, I have seen very few of the third kind. Whenever I do, I try as much as possible and get them to work with us. In our view that is when business transformation truly succeeds.

The post BIG PICTURE vs REAL PICTURE – WHAT IS REQUIRED FOR BUSINESS TRANSFORMATION? appeared first on Global Supply Chain Group | Management And Strategy Consultants.

What I Learnt About Business Transformations Fighting Pirates (Not in the Caribbean)! – Part 1

I was reminded of this story because I was talking about it in a workshop on business transformation last week. I repeat it here because it will be relevant to many people fighting the hard corporate battle, many times without adequate backup.

Here is the true incident without any build-up or embellishment. You have to allow for the fact that this incident is nearly 25 years old, and memory does fade after many years and varied experiences.

Today, this incident almost seems like from a totally another life and place.

I was sleeping in my cabin (about the same size as a studio apartment) when I heard shouts from the deck. On this particular ship, the chief mate’s cabin was not too far above the deck, and since the ship was at anchor in a tropical paradise condition, I had left the portholes of my cabin open to allow fresh sea breeze in. In fact, the air conditioner was defective, and I had to keep the portholes open. I expected a peaceful night at anchor, but alas it was not to be.

The sounds of other boats’ or ships’ engines never disturbed me. The shouts from deck did. Quartermaster (QM) on duty on the deck, and the Officer of the Watch (OOW) were both trying to wake up me, the Bosun, and other crew at the loudest of their voices. I hurriedly put on a T-shirt and rushed outside to the boat deck to get a picture of the situation.

I immediately saw the Quartermaster (QM) and OOW standing on the deck holding a couple of large crow bars or similar implements trying to simultaneously repel boarders and wake up the crew.

Two boats had come alongside. It is difficult to identify the intentions of the boats at sea, especially at night. Most are merely fishermen, petty traders, or offering goods or services to the crew. In high piracy prone areas the standing instructions at anchor are to never let a boat come alongside without challenge and permission. However, this was not a piracy prone area (I will not name the location because I have many good friends from this region and they are sensitive to any perceived criticism of this nature).

QM and OOW were relaxed till they noticed one of the boats throwing a grappling hook over a gunwale (sort of deck railing). That was a clear sign of intransigence, and got QM worked up very quickly, who was shouting at top of his lungs from the deck.

Seeing this, I rushed back into the accommodation, and grabbed the first useful looking implement, a fire axe. Meanwhile, the Bosun had also come on the boat deck with another bunch of crew – each with a useful implement that could be potentially used to defend the ship. Alarm was raised on ships horn, waking everyone up. A crew member was sent to lock all the accommodation doors from inside – barring one, which we were using. Almost the entire ships crew except for a few engineers and the Captain assembled on the port boat deck to defend the ship.

One of the pirates’ nimble ‘associates’ had scrambled over the taut rope – a steep vertical climb of about 20 feet – to the ships deck. He was in the act of pulling up a small rope ladder so that the rest of the lot could scramble up. We still had the advantage, this was the second best time to repel the boarders. The best time would have been to cut the rope from the grappling hook before the first person had boarded.

…Because this blog is getting too long – I have broken the story into two posts. The remainder of the incident is recounted in the blog titled Industrial Age Tools vs Information Age Weapons, which can be accessed by clicking on the link.

That title does give away the key learning which is as follows:

In another set of situations, I see people grappling with impossible odds with inadequate weapons all the time. I am talking about business transformations that I help companies with for the last 19 years since becoming a management consultant after my MBA.

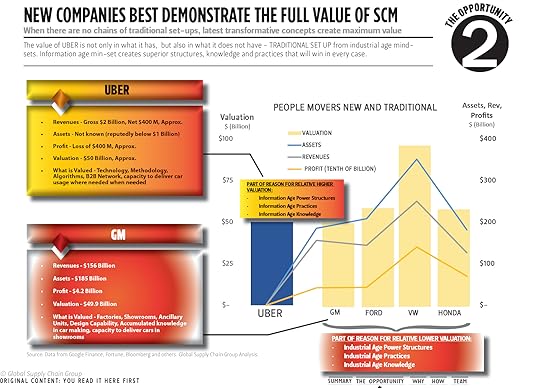

Traditional tools of industrial age – methodologies, knowledge, practices and power structures are regularly deployed to fight superior forces of information age. Most people do not know the difference between the information age weapons and the industrial age tools, till it is too late.

Take a look at the graphic at the end of the blog. And, if you are still convinced that you have everything for the fight ahead – head out to this link to confirm your opinion.

On the other hand, if you are still taking stock of the situation, like I was doing from the boat deck before sending the repelling party out, this link will immediately give you the necessary information to formulate your game plan.

The post What I Learnt About Business Transformations Fighting Pirates (Not in the Caribbean)! – Part 1 appeared first on Global Supply Chain Group | Management And Strategy Consultants.

September 2, 2015

Asian Banker Summit 2015 – Connecting Finance with Supply Chains

On 14 – 16 April 2015 in Hong Kong Convention and Exhibition Centre, Hong Kong, nearly 2000 top bankers and other professionals from all over the world are going to congregate to discuss the future of finance in business and society. (http://forums.theasianbanker.com/summit2015/about-2015-event)

I am speaking in two panels – the opening leadership dialogue around 9.30 or so:

The Supply Chain & Financial Performance Conference Opening Keynote Session

Welcome keynote

Foo Boon Ping, Managing Editor, The Asian Banker

Opening keynote

Alan Bollard, Executive Director, APEC

Leadership dialogue

Global supply chain amidst changing economies

Rapid increase in trade has occurred both in goods and in services. Though at the current stage, the trends of globalization and the commodity cycle seems to be declining. Gone are the days of double digit growths and replaced by a more modest and sustainable one. Why has this happened and how is this affecting the global supply chain?

Multilateralism and trade regionalization against the global backdrop

Reducing barriers: Challenges arise from the trade shift to a low cost but more protectionist country?

The consequence of competitiveness rebalancing for countries around the world

Speakers/panellists:

Robert Yap, Executive Chairman, YCH Group

Paul Bradley, Chairman and CEO, Caprica International

Vivek Sood, Chairman and Managing Director, Global Supply Chain Group

Moderator:

Foo Boon Ping, Managing Editor, The Asian Banker

I am also speaking at 15.30 on another topic:

How banks and financial institution are disconnected from their clients

Post the great financial crisis, clients have moved rapidly to re-configure their business models into B2B networks of supply chains. Most banks and financial institutions have totally missed this rapid transformation and are struggling to stay relevant in the modern supply chain context.

What are the key points of failure?

Why are clients so unhappy with the banks?

What can banks do to recover their position as a trusted advisor in the modern supply chain context?

Featuring:

Vivek Sood, Chairman and Managing Director, Global Supply Chain Group

Here is a short one minute video introduction to my speech:

If you are already attending the summit, or are interested in these topics – I look forward to seeing you at the summit.

The post Asian Banker Summit 2015 – Connecting Finance with Supply Chains appeared first on Global Supply Chain Group | Management And Strategy Consultants.

What Causes the Confusion in Supply Chain Management – I

My last post Confusion about “Supply Chain Management could kill your business” generated several great comments from highly qualified professionals around the world, and in this post I want to explore the reasons for the confusion. Obviously, the confusion is debilitating, and unprofitable. I am sure readers will have their own experiences with the confusion in supply chain world, and can add to the discussion by commenting below.

My last post Confusion about “Supply Chain Management could kill your business” generated several great comments from highly qualified professionals around the world, and in this post I want to explore the reasons for the confusion. Obviously, the confusion is debilitating, and unprofitable. I am sure readers will have their own experiences with the confusion in supply chain world, and can add to the discussion by commenting below.

1. Confusion created by service providers:

in my previous article I mentioned the examples of trucking companies (or warehousing companies) who have painted over their old trucks from XYZ Trucking/Transport to XYZ Logistics to XYZ Supply Chain Solutions without any material change in their capabilities or service offerings. While this kind of ‘branding’ exercise seems harmless enough, and most customers are not ‘fooled’ by such over-representation of the capabilities – it does have several deleterious effects. To give you an example – I was recently asked to answer a question on quora.com by a recent entrant into one of these companies who had entered the ‘field of supply chain’ to make a glamorous career. S/he was disappointed when s/he found that most of the work was rather mundane execution level work in transportation and warehousing. To exacerbate the situation they did not see any prospects of getting even remotely involved in the ‘sexier stuff’ such as supply chain modelling or business transformation.

Evidently, then, this type is hurting careers, reputations and perhaps even the entire industry when these companies represent that what they do is all there is to SCM!

2. Confusion created by those who mistake the a small part for the whole (of supply chain)

No doubt strategic sourcing, logistics, warehousing, production planning, inventory management, demand forecasting all are parts of good supply chain management. Yet almost all of them are quite capable of representing that they constitute the entirety of supply chain management. Look at the way that a number of professional bodies have renamed themselves and pretend to represent the entirety of ‘supply chain’ professionals. Their antics remind of the ancient Hindu tale of 6 blind men which was so well captured by the American John Godfrey Saxe in the poem (Source: Wikipedia):

IT was six men of Indostan

To learning much inclined,

Who went to see the Elephant

(Though all of them were blind),

That each by observation

Might satisfy his mind.

ii.

The First approached the Elephant,

And happening to fall

Against his broad and sturdy side,

At once began to bawl:

“God bless me!—but the Elephant

Is very like a wall!”

iii.

The Second, feeling of the tusk,

Cried:”Ho!—what have we here

So very round and smooth and sharp?

To me ‘t is mighty clear

This wonder of an Elephant

Is very like a spear!”

iv.

The Third approached the animal,

And happening to take

The squirming trunk within his hands,

Thus boldly up and spake:

“I see,” quoth he, “the Elephant

Is very like a snake!”

v.

The Fourth reached out his eager hand,

And felt about the knee.

“What most this wondrous beast is like

Is mighty plain,” quoth he;

“‘T is clear enough the Elephant

Is very like a tree!”

vi.

The Fifth, who chanced to touch the ear,

Said: “E’en the blindest man

Can tell what this resembles most;

Deny the fact who can,

This marvel of an Elephant

Is very like a fan!”

vii.

The Sixth no sooner had begun

About the beast to grope,

Than, seizing on the swinging tail

That fell within his scope,

“I see,” quoth he, “the Elephant

Is very like a rope!”

viii.

And so these men of Indostan

Disputed loud and long,

Each in his own opinion

Exceeding stiff and strong,

Though each was partly in the right,

And all were in the wrong!

moral.

So, oft in theologic wars

The disputants, I ween,

Rail on in utter ignorance

Of what each other mean,

And prate about an Elephant

Not one of them has seen!

Amusingly, the confusion in supply chain management also involves 6 different streams of thoughts.

This post is getting a bit long, so I will cover the rest of the cause of confusions in my next post.

The post What Causes the Confusion in Supply Chain Management – I appeared first on Global Supply Chain Group | Management And Strategy Consultants.

Confusion about Supply Chain Management could kill your business

I am a very social person and I tend to go and visit my alumni meetings for IMD, for Harvard, for Australian Graduate School of Management, Chartered Financial Analyst and many other institutes that I am a member of. And often the question that is asked when I meet someone for the first time is “What do you do?”

I am a very social person and I tend to go and visit my alumni meetings for IMD, for Harvard, for Australian Graduate School of Management, Chartered Financial Analyst and many other institutes that I am a member of. And often the question that is asked when I meet someone for the first time is “What do you do?”

When I explain to them that I ran a company called Global Supply Chain Group and I help companies improve their supply chain management, most of the people I meet still do not fully understand what supply chain management is, including those in the alumni of my business schools or Chartered Financial Analyst Institute or Law school.

So much so that occasionally I even get asked questions such as “So what kind of chains do you supply to the businesses?” At a more informed level, many people confuse supply chain management with “supply” or procurement or ‘strategic sourcing’.

The most common misconception is, however, between logistics and supply chains, and frequently I explain the difference between these two. This confusion is exacerbated by trucking companies who have painted over their old trucks from XYZ Trucking/Transport to XYZ Logistics to XYZ Supply Chain Solutions without any material change in their capabilities or service offerings. Moreover, many supply chain managers, directors and vice-presidents who come from logistics, 3PL or such companies exacerbate this confusion by not expanding their skill-set. They rely on CEO’s (and other stakeholders’) lack of differentiation capability between logistics and supply chain to narrowly define their role and stay well within their comfort zone.

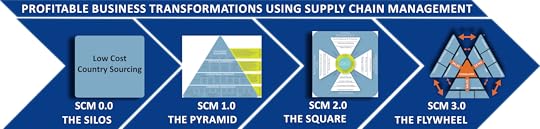

I answer the question about what we do saying that we help create profitable business transformations using supply chain management as a very effective and balanced tool-kit, contrasting such business transformations against purely soft-skills based transformations (such as culture change) that rarely stick in rough and tumble of real life companies, and against purely hard-skill based transformations (such as process re-engineering) which cause a lot of angst.

I show them a simple diagram such as the figure below to explain the progression of supply chains from a lower level of sophistication to a higher plane of profitability.

This starts a discussion on the various generations of SCM (supply chain management) and how they grow in sophistication over each succeeding generation. Those are the type of questions I can illustrate easily with case examples and real life stories. There will be a lot of these stories in this book.

I make it more real to people by explaining to them that we help companies configure business-to-business networks in a much better manner than they have done in the past. It used to be the case, or even still is now, that business-to-business networks are configured in an ad hoc manner on an as-needed basis. In most cases, these relationships are never formalized and fine-tuned to an extent where companies would create robust collaborative working environments to help develop new products, or create pipeline of products, to optimize profitability or to help manage the cash-to-cash cycles in the most productive manner.

The difference between a well-functioning business-to-business network and suboptimal one is a nearly 5 times difference in profitability. Now that is something that will easily intrigue most CEOs and business school graduates. When people hear that a good business-to-business network can increase profitability by up to 5 times by improving the cash-to-cash cycle, by improving the transactional optimization of profitability, by helping create new products faster and better, and by outsourcing better, most people are very interested to clear the confusion about how current generation supply chain management works.

The post Confusion about Supply Chain Management could kill your business appeared first on Global Supply Chain Group | Management And Strategy Consultants.

Why Collaboration is the NEW Advantage?

For decades, if not centuries, the economists have been extolling the virtues of competition. No doubt, competition unleashes forces lying dormant within human psyche – forces of of one-upmanship, jealousy, keep up with the jones, and similar nature.

Of course, the economists rarely look into the psyche behind the actions and, even if they do – they would use different language to describe these forces. And they accurately describe the positive effects of such forces in fostering new products, new services, and better products/services at lower prices. Yet, they naively ignore the downside – that is why economists are rarely good leaders.

In the 1980s, at the peak of the competitive drive in the epicentre of competition, Michael Porter of Harvard wrote an entire book dedicated to competitive advantage. In hindsight, this immensely successful book, perhaps also epitomised the high point of the competitive revolution. Those of us who had doubts about this single minded focus on competition kept mostly quiet – after all Harvard was supposed to research these things extensively, and know better.

Not too long after that, Jefferey Skilling, another Harvard guy took this competitive drive to its extreme conclusion before the firm he was leading – Enron – exploded in a volley of absurdities that extreme of anything can lead to.

Perhaps, that was also the turning point in the corporate thinking. Collaboration became slightly more acceptable. Competition was good – but there too was time and place for collaboration. Perhaps your suppliers and customers had a role to play in your success. Perhaps your Collaborative Network or B2B Network is important to your profits. Perhaps CEOs should pay more attention to their supply chains as they morph into collaborative B2B Networks.

It is true that some of the most admired corporations in the world today are led by CEOs who have intuitive mastery of supply chains. The likes of Apple, Amazon and now Tesla are global corporations with a truly global business network and supply chain. On an objective scale measuring the quality of their B2B Network these are some of the most successful companies on earth today. For example – if you read Steve Jobs biography by Walter Isaacson, you will see this quote:

The phrases he used were “deep collaboration” and “concurrent engineering.” Instead of a development process in which a product would be passed sequentially from engineering to design to manufacturing to marketing and distribution, these various departments collaborated simultaneously. ” Our method was to develop integrated products, and that meant our process had to be integrated and collaborative,” Jobs said.

Yet, an average company is still far behind its leading counterparts when it comes to globalization of their B2B networks. Let us look at two hard truths about the average company before we talk about this conundrum.

Most companies, start out as local or regional winners who expand out from their home turf to sell into national and global markets. Nothing unusual there. However, it is their attitude about globalization that is troubling. We will sell overseas, we might even make it there, but we will not make them partners of our supply chains. How far can they go with this attitude? If they really thought global, they would create global supply chains at the start of process, not a country centric supply chain that has a global appendage attached to it. Everyone is more comfortable on their home turf, but only those who can make all turf their home turf can truly win the high stakes game of globalization.

Most companies, start out as local or regional winners who expand out from their home turf to sell into national and global markets. Nothing unusual there. However, it is their attitude about globalization that is troubling. We will sell overseas, we might even make it there, but we will not make them partners of our supply chains. How far can they go with this attitude? If they really thought global, they would create global supply chains at the start of process, not a country centric supply chain that has a global appendage attached to it. Everyone is more comfortable on their home turf, but only those who can make all turf their home turf can truly win the high stakes game of globalization.

Second point, equally relevant, is the key question why are CEOs so scared of supply chains? Yes, it is complex and technical, but if worlds’ best CEOs such as Steve Jobs and Michael Dell want to make sure that they personally have a good handle on their companies’ supply chains, then why it is beneath the dignity of CEOs leading companies 100 times smaller? If they do not get used to it their competitors will beat you to the pip.

Complexity comes from new technologies, and from the seemingly infinite business possibilities opened up by these technologies. Digitization of supply chains is the other side of the same coin called “the internet of things”. Intelligent machines everywhere talking to each other all the time, creating solutions that ease consumers’ lives is not going to be a dream for too long. At the same time, massive real-time data will be created and stored. This will need to be used intelligently and effectively to further enhance consumer lives.

Robots and automation will make 60% of the current jobs redundant in 10 years. Digital 3D printing will finally make the mass customization a reality. We are not talking about a far-fetched future. All these technologies exist right now – what is lacking is a will to use them methodically.

Both of above points are hard facts that are not going to change, no matter how you try to wish them away. So, what is the solution?

Before looking at the solution, let us look at a parallel, or a metaphor.

Steamship Titanic sank when it hit an iceberg going full steam ahead in fog. Since that day, fog navigation is every Ship Captain’s worst nightmare. I still remember when I joined sea as a cadet, the moment the ship hit a fog bank – Captain would take over the navigation personally, station lookouts on Crows Nest, Monkey Island and many other exotic sounding places on the ship and try and listen to foghorns of other ships – all this despite the presence of 2 wholly functional radars.

Some captains were trained in the art of navigation long time ago – when radars did not exist. Many of these ‘navigate by feel commanders’ never got comfortable with radars – to their own peril and to the peril of their shipboard crew. As a result, shipping companies gradually eased these people out of command, making way for a newer generation of Masters who could make full use of available technology appropriately.

Capacity to handle the additional complexity is now a ticket for entry.

Rethink your business models. Rethink your business processes. Massive waste, customer angst, and massive redundancy can be avoided if CEOs could think clearly and get past the complexity. Educate the government and academia to start making the changes to education system now. What is the point of churning out graduates totally unsuited to the future world when they enter the workforce.

A lot of complexity is created by self-interested parties to muddy up the waters. Sure they can stagnate the progress in one country, but that will only mean that companies from other countries will leapfrog the US companies.

Leading companies everywhere are outward looking and embed themselves into a global B2B network with a lot more ease than their average counterparts. Look at Zara (Inditex) a 87 Billion Euro market cap corporations starting out of rural Spain that is fast globalizing its supply chain. Most Asian companies fast globalised their supply chains in search of collaborative advantage stemming out of B2B Networks – look at ArcelorMittal a steel corporation (with market cap of nearly $18 Billion and Total assets of nearly $100 Billion) originating out of a small operation in Indonesia.

A massive opportunity to lead the business world into its next renaissance exists right now. Technologies mentioned above are supplemented by societal and economic transformations around the globe. This will lead beyond SCM 3.0 that we talk about a lot in this book – into the realms of SCM 4.0. I know it is just a concept at this stage – yet unmanned ships, aircrafts, cars will run the logistics of future. Unmanned forklifts will do the picks and packs in warehouses of the future. Robots will man the assembly lines of future. And, print on demand 3D solutions will make half the inventory redundant. Think about the massive changes this will entail in business models.

A massive opportunity to lead the business world into its next renaissance exists right now. Technologies mentioned above are supplemented by societal and economic transformations around the globe. This will lead beyond SCM 3.0 that we talk about a lot in this book – into the realms of SCM 4.0. I know it is just a concept at this stage – yet unmanned ships, aircrafts, cars will run the logistics of future. Unmanned forklifts will do the picks and packs in warehouses of the future. Robots will man the assembly lines of future. And, print on demand 3D solutions will make half the inventory redundant. Think about the massive changes this will entail in business models.

Now think about the end consumers around the world. New generations share more in common across the national boundaries than with the past generations in their own patch. They are hyper-connected, super-informed and very vocal about their rights, needs and wants. They are also very disloyal to any particular brand. In fact the entire concept of branding is going through a revolutionary change.

To lead will require CEOs to adopt three critical viewpoints: create global supply chains, embrace the global customers’ voice and cut out the complexity by using technologies. That will ensure that these corporations will thrive well past this century.

This has been a relatively thin and inexpensive book when compared to management tomes. But it is still fairly long when you consider that the essence of all Greek philosophy was summed up in two words by Socrates – KNOW THYSELF – also inscribed in the forecourt of the Temple of Apollo at Delphi. That is probably a good action point to use this material – particularly, if you are convinced that your company has none of the problems described in this book. I invite you to take the complementary survey by sending me an email on info@globalscgroup.com . You may be surprised by the result.

Having done that you may find that you want some of your people to delve deeper in this material. For that purpose, we produce three exclusive strategic reports which might be a good starting point for them. Of course the next danger will be when people start taking collaboration too far so be prepared to find a good balance between competition and collaboration.

Source: “UNCHAIN YOUR CORPORATION”

The post Why Collaboration is the NEW Advantage? appeared first on Global Supply Chain Group | Management And Strategy Consultants.

![By Volvo_Ocean_Race,_Målgång_Göteborg,_Pirates_of_the_Caribbean.jpg: Tord Strømdal, Sweden derivative work: Cryonic07 [CC BY-SA 2.5-2.0-1.0 (http://creativecommons.org/licenses/by-sa/2.5-2.0-1.0), GFDL (http://www.gnu.org/copyleft/fdl.html) or CC-BY-SA-3.0 (http://creativecommons.org/licenses/by-sa/3.0/)], via Wikimedia Commons](https://i.gr-assets.com/images/S/compressed.photo.goodreads.com/hostedimages/1443298286i/16345222._SX540_.jpg)