Vivek Sood's Blog, page 44

June 8, 2016

Are You Making What You are Worth

By: Vivek Sood-Managing Director, Global Supply Chain Group

One of my posts on LinkedIn sparked a lot of interest and a healthy debate. I am not sure about the reason for interest but seems like people agree with the above statement, as well as its reverse: The person who does less than s/he is paid for, will soon be paid less that s/he does.

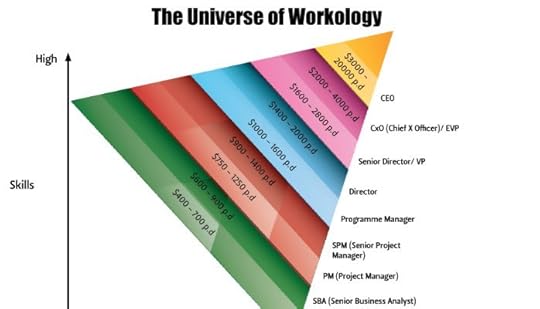

So, what do you get paid for? And, are you getting paid for what you are worth? What skills do you bring to the job? What attitude to you bring? Are you being rewarded for the two? What can you do? Use the figure below as a guideline:

You can find comments on LinkedIn: http://www.linkedin.com/pulse/you-making-what-worth-vivek-sood?trk=mp-author-card

The post Are You Making What You are Worth appeared first on Global Supply Chain Group | Management And Strategy Consultants.

Changing Role of Supply Chain Management in Digital Economy

By: Vivek Sood-Managing Director, Global Supply Chain Group

In the rapidly changing world – role of supply chain is constantly evolving. There are now at least three generations of supply chains and the confusion about the roles and expectations is leading to massive losses inside the corporations.

Here are some insights and excerpts from my speech on this topic.

You can see the video on https://vimeo.com/154241299

Everyone has a circle of influence – in LinkedIn, Facebook, Twitter, contacts and colleagues. If these ideas make sense to you, share them far and wide. If they do not – make a comment here.

To know more about Vivek Sood, make sure to visit the website viveksood.com/ or globalscgroup.com/

For any questions or comments, feel free to contact us at contact@globalscgroup.com.

You can find comments on LinkedIn: http://www.linkedin.com/pulse/changing-role-supply-chain-management-digital-economy-vivek-sood?trk=mp-author-card

The post Changing Role of Supply Chain Management in Digital Economy appeared first on Global Supply Chain Group | Management And Strategy Consultants.

Tinderization of Human Courtship – and What It Means for the Business Ethos

By Vivek Sood-Managing Director, Global Supply Chain Group

https://commons.wikimedia.org/wiki/File:Eugen_de_Blaas_The_Flirtation.jpg

I vaguely recall reading a research paper on human courtship by a US professor, where he hypothesised a 13 stage courtship process starting with eye-lock to for-ever-after. He had studied several human societies – ranging from primitive isolated tribes to modern urban tribes and concluded that the process was uniformly similar, irrespective of the locale. Sure, it was based on previous studies of animal courtships, and an animalistic view of humanity – but the basic premises was that this process, if short-circuited, generally led to dissatisfaction with the relationship in the long run.

What triggered this thought was this news item on Tinder titled – Research: Estimated 750,000 Tinder users have pubic lice, and I started thinking about how Tinder is changing the game of human courtship by re-engineering the courtship process. By making it easier to connect, and taking away the awkward moments at the start of the process, the entire process can be made easier, faster, and more efficient.

But is it more effective?

I have no personal experience, but the research from the professor quoted above, indicates that the free-agent society may turn out to less happier in the end.

Is this the case of process efficiency sacrificing overall goal of the process? Efficiency killing the effectiveness?

When thinking about the business implications of the process, I will not go into the societal impact of the free-agent society, or economic impact of the free-lance economy. Rather, I will limit my current thinking to a discussion I was have over the last 2-3 weeks.

One of our clients had been sitting on a project proposal for months even though he knew that the project was essential to survival of his company. This large project involves a fairly large team, and is expected to generate significant net savings. Yet, for some reason or other, he was not signing off the project. This is not unusual in our game.

Then suddenly 2 weeks ago he wanted to arrange a meeting and short-circuit the project work and complete the project in nearly half the time. I explained to him that the quality of the data, and the analysis would not be robust enough for the purpose of the overall project. In fact, it could be counterproductive.

Unless he is strategically withholding information on his reasons, the outcomes will not be in his best interest, and hence not in ours either.

Is this another case of efficiency killing the overall purpose. Sacrificing effectiveness for the sake of efficiency?

How many times have seen this happen?

The post Tinderization of Human Courtship – and What It Means for the Business Ethos appeared first on Global Supply Chain Group | Management And Strategy Consultants.

What Do Roads in Rural Bali Have to Do With Supply Chain Digitization?

By: Vivek Sood-Managing Director, Global Supply Chain Group

Digitization is the buzzword of the moment in Supply Chain. Going by the number of articles and posts on digitization, you would think that the pope has just discovered religion. In fact, I recently read an article which used the word ‘digitization’ nearly 100 times in about 4 paragraphs. It talked about demand digitization, supply digitization, inventory digitization, fullfilment digitization, planning digitization, and many such things.

Is this really that new? Since the days of SAP (late 80s), or before, digitization has been gradually gaining pace. Yet, current articles are making out as if there is a switch you flick – and suddenly you have ‘light – aka digitization.’ Reality is far more interesting and juicy.

Thinking of digitization, I was reminded of our business transformation projects and trouble with getting accurate data.

Despite spending hundreds of millions of dollars on ERP systems, (and in many cases over a billion dollars), most companies still fall way short in terms of their data – both in terms of accuracy and completeness.

Before starting almost every project we are assured that the data will be in our hands within a few days – at the most. Typically, we count ourselves lucky if the data extracts are available within 3 weeks, and are accurate enough to be useful for analysis.

But, this blog post is not about the barriers to digitization, rather it is about the nature of digitization itself. Why the data is not readily available, and why is it of such poor quality that it is barely useful for most analysis – this discussion will open up a pandora’s box of pent up feelings within the companies. Most technology companies are clueless about the human element, and continue to plough ahead in darkness – and blame their customers for technology failures.

Reading the recent spate of articles on digitization left me with a distinct impression that another element which they show a marked ignorance about is the nature of digitization itself. The belief that it is a binary switch where you get technology and suddenly your company is ‘digitized’ is far from reality.

Recently, I had the occasion of spending nearly a month on a sabbatical and family holiday in the island of Bali. I happened to travel over the entire length and breadth of the island during this period and noticed the state of the roads varied significantly depending on how far I was from the ‘touristy Bali’. What started as paving over the village footpaths, would gradually morph into high quality road, which would later be widened to accommodate growing traffic, and later replaced by a highway/motorway in parts.

Most island roads were however, still narrow village paths paved over for modern transport. All this existed simultaneously at the same time and will continue to exist well into the future – with gradual upgrades from one level to next over the years.

That is the state of digitization of supply chain and will continue to be, with gradual upgrades from one level to next well into the future. We have no Y2K type crisis (remember that?) that will force upgrades, and dollars are scarce in most companies that do not enjoy some historical or political advantage. No amount of hype from IT vendors is going to change this reality. Also, CEOs and CFOs of long memories of past IT projects that failed to fully deliver. Perhaps the next generation of executives will be gullible enough to fall for the same hype again.

You can find comments on LinkedIn: http://www.linkedin.com/pulse/what-do-roads-rural-bali-have-supply-chain-vivek-sood

The post What Do Roads in Rural Bali Have to Do With Supply Chain Digitization? appeared first on Global Supply Chain Group | Management And Strategy Consultants.

Technology Without Purpose is Like a Missile Without a Guidance System

By: Vivek Sood-Managing Director, Global Supply Chain Group

Nobody sets out thinking, I have no purpose for bringing this technology into our company, but I will do this anyway (well a few rare twisted souls might do it – totally driven by a side deal that meets their self-interest). Yet, post-hoc analysis reveals so many IT projects fail due to a variety a reason that one has to ask – what happened to the original purpose. Where did not lose track of that?

I have written in detail earlier about why IT projects fail. For example in my book THE 5-STAR BUSINESS NETWORK, I wrote the following:

Many large scale information technology deployments derail!

Data, anecdotes and case histories abound on the misapplication of information technologies for supply networks. Not too many years ago, a very large corporation operating worldwide, made news with the downgrading of their earnings expectations due to supply chain system’s implementation setbacks. The expectation was that the new system would reduce the new production cycle from 1 month to 1 week. Furthermore, it would better match the demand and supply of its products to place the correct products in the right locations and quantities, all at the right time – a very lofty goal. The company spent an enormous amount of money, exceeding US $400 million in order to achieve its aim. However, the software system ‘never worked right’. It caused the factories to crack out too many unpopular products and not enough of the trendier ones in high demand. While making the earning downgrade, the CEO asked the rhetorical question, ‘is this what we get for $400 million?’

The market analysts were not surprised. One respected market analyst [AMR] commented, ‘ fiascos like this occur all the time but are usually kept quiet unless they seriously hurt the bottom line.’ Another respected market analyst commented that while the CEO made it sound like it was a surprise for him, if he did not have checkpoints for the projects, he does not have control over his company. A third analyst commented that companies are confused by escalating market hype and too often underestimate the complexity and risks. Another [Forrester Research] commented ‘when the software projects go bad companies are more likely going to scurry up and cover it up because they fear that they are the only ones having trouble. But far from it; our conversation and research reveals this company was not unique or the only one having this kind of trouble‘.

Despite their lofty goals, many of the large information technology deployment projects derail. It takes time for the word to filter out because, in most cases, the executives involved in the process are far too embarrassed to talk about what happened. They do mutter among themselves; after several similar instances the mutterings become more vocal and a trend emerges where a number of people start talking about the shortcomings of the system itself or the implementation process or of the time taken for implementation. Because the cost of this failure is so high – greater than $400 Million in the above case – it is instructive to understand the real root causes of this failure. I am not looking to apportion the fault or apportion the blame in this chapter.

30 years of accumulated wisdom is now available

However, it will be a fallacy not to learn from all the accumulated wisdom of the past. After all, those who do not learn from history are condemned to repeat the same mistakes again and again. This will enable us to understand the steps we can take from the very beginning to increase your probability of success. This will also allow you to confidently move forward with Business Network Information Technology system selection, integration and use in order to achieve the results that you set out to achieve.

The supply networks information technology projects have become bigger and bigger over the last 15 years. It is quite customary now to start with an expectation of spending around $ 50 million but end up spending in excess of $200 million on systems renewal projects.

Rough estimates indicate that, even today, about one third of these projects are cancelled without delivering any benefits, after spending more than $100 million. Another third of the projects are not cancelled, but fail to deliver significant parts of what they set out to achieve. Only one third of the projects achieve most of their strategic goals, but many still incur several budget upgrades and time overruns.

Why is this pattern of failure repeated over and over again?

In general, the original purpose is lost somewhere between the scope creep #2 and #3, and thereafter technology becomes an end in itself, and not a means to achieve a business outcome. There is an admirable drive to digitization underway – but does it suit the purpose of all businesses in all locations?

You can find comments on LinkedIn: http://www.linkedin.com/pulse/technology-without-purpose-like-missile-guidance-system-vivek-sood?trk=mp-author-card

The post Technology Without Purpose is Like a Missile Without a Guidance System appeared first on Global Supply Chain Group | Management And Strategy Consultants.

Why Executives Underestimate the Impact of Supply Chains?

By: Vivek Sood-Managing Director, Global Supply Chain Group

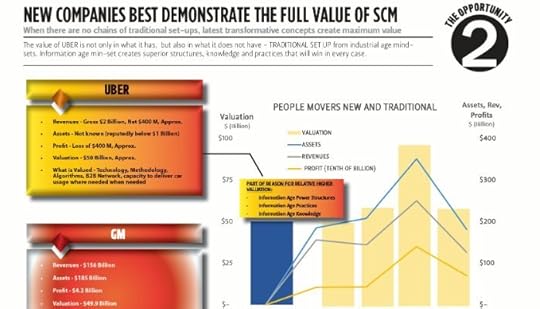

CFOs are not the only ones who underestimate the impact of Supply Chains on modern corporations. CMOs, COOS and even CEOs are not fully aware of the full potential of supply chain management. When the potential is not fully known, expectations are too low and results are even lower. This speech and will show you the impact of Supply Chain Management in Modern Corporations.

Click on this link to watch the video https://vimeo.com/154126502

To know more about Vivek Sood, make sure to visit the website viveksood.com/ or globalscgroup.com/

For any questions or comments, feel free to contact us at contact@globalscgroup.com

You can find comments on LinkedIn: http://www.linkedin.com/pulse/why-executives-underestimate-impact-supply-chains-vivek-sood

The post Why Executives Underestimate the Impact of Supply Chains? appeared first on Global Supply Chain Group | Management And Strategy Consultants.

June 7, 2016

My Experience With Freight Cost Reduction Using Supply Chain Software

By: Vivek Sood-Managing Director, Global Supply Chain Group

https://www.flickr.com/photos/eleni_pap/4520685648

One of the reasons I invest so much time and resources of our company in keeping current with the information technology is that good supply chain depends almost entirely on good information. And, your information is only as good as the technology deployed to collect, collate, store, parse and reproduce the information on demand.

It is no secret that most of our supply chain transformation projects are highly time intensive and heavily data driven. We trust all participants in the supply chain, and we verify everything – from several angles. However, if you have been working in freight cost reduction for over 30 years like I have been, you know the reality on ground.

But that raises a big question about the data. Specifically – ‘a data scientist can only be as good as the data s/he has.’ In most projects the data is woefully inadequate – even today in 2016. Rather than talk about our current freight cost reduction projects, I will give an example from several years ago (for sake of propriety and confidentiality I will disguise some details).

When our team completed the initial 8 week diagnostic on that project for an industrial corporation with $1.3 Billion supply chain, it was clear that despite heavy investment in SAP, supply chain data was far from adequate. In fact for ocean shipping it was so inadequate that we had to employ temporary staff in to digitize a paper trail of transaction details in order to conduct our analysis. I could probably spend another 5,000 words just writing about how difficult it was to get hold of the data, and then how difficult it was to verify the veracity of that SAP extracts. After all my team was sharing their travails with me on a daily basis.

We had signed a fixed price 10 week contract for completing the work. We anticipated the usual data problems for the first week or 2. What we did not anticipate was a 5 week run around to get hold of the SAP extract, and then another 2 weeks to verify its veracity. As a result our team had to find additional resources, and time, to conduct a 6-7 week analysis in 3-4 weeks in order to meet the deadline for senior executive off-site meeting scheduled for the end of the diagnostic.

I asked the team to make full record of all the inadequacies they found in the SAP set-up so that we could provide recommendations on system upgrade to facilitate good supply chain planning, control and decision making. While this was not something our company worked on, and it was not even part of the project brief, it was going to be extremely useful for future SAP upgrades in the company. After all limits of any machine are only discovered when it is being used at its limits. (Now that upgrade is a subject for another blog, at some other time).

It was clear to all that SAP was set-up mainly for financial reporting purposes, and supply chain management was an afterthought to the transaction recording. As a result, the system did a marvelous job of providing aggregate data on financial well-being of the organisation. It also facilitated adequate drilling-down of financial transactions. Yet linking those financial details to actual supply chain movements was less than adequate. In fact, for ocean shipping, nearly 25 hand-over points in the transaction workflow were all aggregated into one single SAP transaction.

Our team diligently recorded all the issues with supply chain transaction processing that we found during our strategic diagnostics of supply chain. Several pages of tables similar to the one below were cross-checked, verified and created.

[image error]

Not just that, an annex report with high level requirements for future upgrade of SAP was also created, even though this was not part of our original project brief. Unfortunately, I am disinclined to publicly share even sanitized version of a sample extract out of this report . privately, I might be able to share sanitized extracts in case your team is going through a process of making your SAP installation more user friendly to your digitized supply chain.

I chose this old case example for several reasons. Firstly, it has gone through a full cycle of business and information technology outcomes, which are now well known.

On business side our supply chain transformation project was a massive success. In fact the global head of supply chain (who later became the CEO) wrote this in the foreword to one of my books:

When I engaged Vivek’s services for supply chain transformation in one of the companies I was heading, we expected the careful and methodical approach that he was famous for. Outsourcing was only one of the components of our supply chain, and at the time we did not think it was even a particularly important one.

I was already convinced that critical business turnaround can only be achieved by taking an end-to-end supply chain approach to this transformation. I was pleased to note that the original target set for 3 years was surpassed by almost 70% in just 18 months – providing graphic evidence of the full power of these ideas in action.

On the information technology side, the supply chain requirements were never fully translated into a usable system resource base. I will not go into the reasons in this blog.

SAP has since invested in Ariba – a procurement management software. unfortunately, the confusion between procurement and supply chain management continues to persist. A number of journalists, and even business professionals use the terms interchangeably.

On the IT side the supply chain workflow still remains inadequately supported.

A few newer companies are starting to crop up, yet a great majority of them (to some degree) seem to be falling into the same traps that their predecessors fell into above. In my next blog I will cover this in more detail.

Meanwhile, share your experience with SAP, Ariba or other so called supply chain transaction processing software systems. Not only will you add to the accumulated IP on supply chain system, but also you may earn a copy of the book quoted above.

You can find comments on LinkedIn : https://www.linkedin.com/pulse/my-experience-supply-chain-software-vivek-sood

The post My Experience With Freight Cost Reduction Using Supply Chain Software appeared first on Global Supply Chain Group | Management And Strategy Consultants.

February 7, 2016

The Tech Revolution: A Disruption or An Ally

The digital revolution (aka tech revolution) has changed the way we live, work and play. The boom of software and IT solutions have caused disruption and realignment for businesses. When business intelligence is implemented and used effectively there is a real pay-off. There are still a lot more developments in technology to come and businesses that have their finger on the pulse have a huge vantage point. For business transformation, the key question will be how IT can facilitate the process without everyone feeling enslaved by technology.

For more information on the answer to this critical question please refer to my newest book Unchain Your Corporation, or visit http://unchainyourcorporation.com .

The post The Tech Revolution: A Disruption or An Ally appeared first on Global Supply Chain Group | Management And Strategy Consultants.

February 3, 2016

A Revamped Business Model: The Introduction of Customer Centric

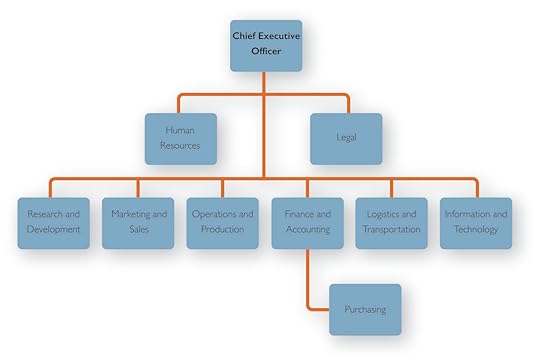

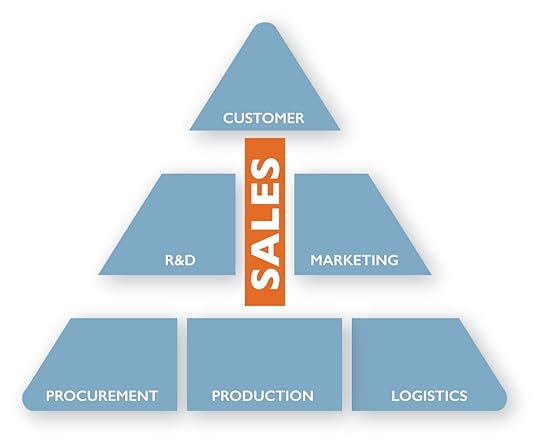

New challenges need new responses. The common organizational model looks like the generic drainpipe structure, meeting the mammalian need for an ordered hierarchy and flow of power within a business.

The Traditional Business Model

Most companies have evolved in the last 2 decades and their functioning has become almost entirely customer centric. Their customers’ priorities drive most of the business workings. The traditional drainpipe model frequently stifles customer responsiveness and innovation, therefore there is a clear need for a new standardized customer centric model of business.

The new customer centric model starts with customers at the apex of the organization. It is the customers’ needs which the organization is trying to serve, so directly aligned with the customers is the sales team. The function of the sales team is to have an intimate understanding of the customers’ needs. Only then can an organization create successful products. An organization can outsource almost everything else it does, but it can never outsource its sales.

Two other key functions which are equally important and support the sales team is marketing and research & development. Between these three we form the top tier of the modern organization’s structure.

The Customer Centric Business Model

The post A Revamped Business Model: The Introduction of Customer Centric appeared first on Global Supply Chain Group | Management And Strategy Consultants.

February 1, 2016

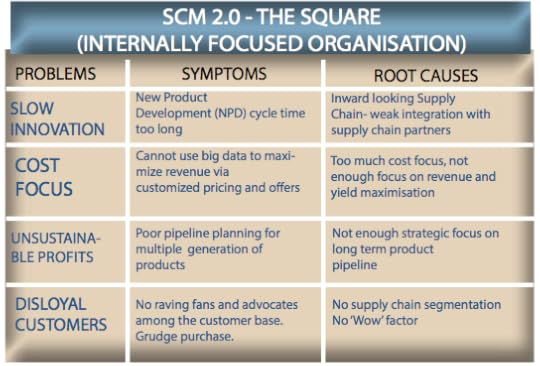

If Your Business Has Too Much Internal Focus, You Could Be Missing Out

It’s no surprise that customers hate companies with too much internal focus. As organizations free up their inter-departmental planning from rigidities, the communications start to bloom. Efficiency improves considerable and everybody starts running together, faster. However, a higher set of problems emerge due to lack of external focus – on suppliers, customers, and end-consumers. Many times everybody inside the organization is running together, faster, but in the wrong direction.

Problems With Internal Focus

The post If Your Business Has Too Much Internal Focus, You Could Be Missing Out appeared first on Global Supply Chain Group | Management And Strategy Consultants.