Scratch-built Strandbeest model

After watchine a video Adam Savage linked to early this year, I became fascinated with Theo Jansen's Strandbeests. And while my niece Emma was staying with us for a birthday weekend, I showed her the videos of various Strandbeests walking on the beach. She was captivated. And I thought it would be nice to build a table-top model of one...but instead of buying a kit, I opted that Emma and I should scratch build one together. I watched a few more videos, and looked at a few of the model kits online, then Emma and I hit a craft store or two and bought various sizes of popsicle sticks, dowels, florist's wire, round toothpicks, and glue.

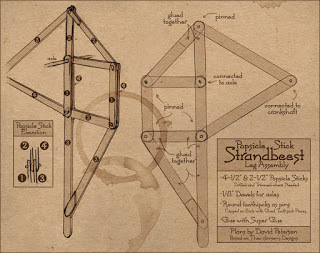

After watchine a video Adam Savage linked to early this year, I became fascinated with Theo Jansen's Strandbeests. And while my niece Emma was staying with us for a birthday weekend, I showed her the videos of various Strandbeests walking on the beach. She was captivated. And I thought it would be nice to build a table-top model of one...but instead of buying a kit, I opted that Emma and I should scratch build one together. I watched a few more videos, and looked at a few of the model kits online, then Emma and I hit a craft store or two and bought various sizes of popsicle sticks, dowels, florist's wire, round toothpicks, and glue. I'd broken down the leg into a simple diagram I traced on to the craft paper we used to protect my dining room table. On the right you can see a single leg assembly with the diagram on the paper below. Once we had our plan, and I could visually decribe to Emma what we were doing, I put her to work cutting and drilling popsicle sticks, and then glueing sub-assemblies. Emma had never used a hobby knife or a drill before, so it was exciting for me to teach her how to use them, and exciting for her to do something so new to her.

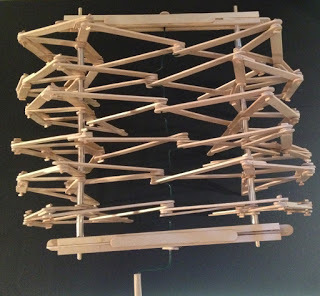

I'd broken down the leg into a simple diagram I traced on to the craft paper we used to protect my dining room table. On the right you can see a single leg assembly with the diagram on the paper below. Once we had our plan, and I could visually decribe to Emma what we were doing, I put her to work cutting and drilling popsicle sticks, and then glueing sub-assemblies. Emma had never used a hobby knife or a drill before, so it was exciting for me to teach her how to use them, and exciting for her to do something so new to her.  After hours and hours, Emma conked out, and I finished the assembly in the wee digits of the morning. But, it still needed fine tuning. The model Strandbeest has sat in my studio since March, unfinished and fragile, until I got the urge a few weeks ago to repair, tweak, and polish off the last bits of the model. To the left, you can see the finished version, which may not look too different from the older photos above... Directly below, you can watch a video of our hand-crank model in action, then further below, I'll document some details and share the rough plans.

After hours and hours, Emma conked out, and I finished the assembly in the wee digits of the morning. But, it still needed fine tuning. The model Strandbeest has sat in my studio since March, unfinished and fragile, until I got the urge a few weeks ago to repair, tweak, and polish off the last bits of the model. To the left, you can see the finished version, which may not look too different from the older photos above... Directly below, you can watch a video of our hand-crank model in action, then further below, I'll document some details and share the rough plans.Popsicle Stick Strandbeest from David Petersen on Vimeo.

I put clear tubing spacers between each leg joint to allow less wiggle and slop as everything moved

I put clear tubing spacers between each leg joint to allow less wiggle and slop as everything moved The front chassis that holds the axles was never completed originally. So, I completed what needed to be done, and reinforced both ends to prevent racking and to avoid catastrophe.

The front chassis that holds the axles was never completed originally. So, I completed what needed to be done, and reinforced both ends to prevent racking and to avoid catastrophe. All of the moving joints are pinned with round toothpicks that have smaller cuttings of the same material glued across the ends to form a capital "I" shape. Many of these needed minor repairs and re-gluing.

All of the moving joints are pinned with round toothpicks that have smaller cuttings of the same material glued across the ends to form a capital "I" shape. Many of these needed minor repairs and re-gluing. With the chassis secured, I was able to trim down the length of the axles. I left a bit of them showing so that seeing the crafted materials were part of the model's charm.

With the chassis secured, I was able to trim down the length of the axles. I left a bit of them showing so that seeing the crafted materials were part of the model's charm. Rough plans & notes for those inspired enough to try their own hands at one.

Rough plans & notes for those inspired enough to try their own hands at one.

Published on December 08, 2015 06:00

No comments have been added yet.

David Petersen's Blog

- David Petersen's profile

- 339 followers

David Petersen isn't a Goodreads Author

(yet),

but they

do have a blog,

so here are some recent posts imported from

their feed.