Blade of Bonding

A while back we visited our Baron and Baroness at their home. The forge got stoked up and blade smithing happened – oops!

My wife was one of the group that got lured into the world of fiery coal, glowing metal, and the ringing of steel on steel.

She came away from it with a blade and a desire to do more.

She said I needed to guide her in completing the task. She was not satisfied with having smithed a blade but wanted to have the experience making a full knife. This was going to get into fields she hadn’t played in before, but I for one was not going to dissuade her.

Welcome to the dark side, baby!

She has done 98% of the work. I have shown her technique, I have directed her with words and diagrams, and I have made recommendations and told her ‘what I would do at this point’ – she did the actual making.

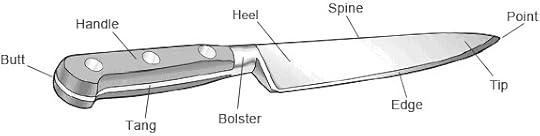

She cut, cleaned, and fit together the bronze for what would best be called the ‘bolster’. Then soldered it onto the blade – not the usual way but it helped secure a possible weak point in the blade.

She cut the purple heart and carved the handle into the right size and shape for proper function, while also forming it into a seahorse for visual appeal.

She went with epoxy for connecting blade to handle. Nothing wrong with that. The final edge was put on with a fine tooth file and then a sharpening stone. It cuts a raw potato – so I’d say that makes it a real paring knife!

I’m really proud of my lovely lady.

Filed under: MIscellaneous, SCA Tagged: blade, bladesmith, forge, paring knife, wife