DIY – How To Build Your Own Oak Home Bar

IF I CAN DO IT… anyone can.

IF I CAN DO IT… anyone can.

Sure, I’m a guy who works with my hands… on a computer keyboard!

I write novels, I don’t build furniture. But sometimes, circumstance, bravery (or foolishness) collide. I am writing this blog to hopefully show that if you want it bad enough… you can build it. I documented most of my steps along the way with photos, so you can see all of the steps I went through. All of the photos on this page are thumbnails – click on them to see full-size versions.

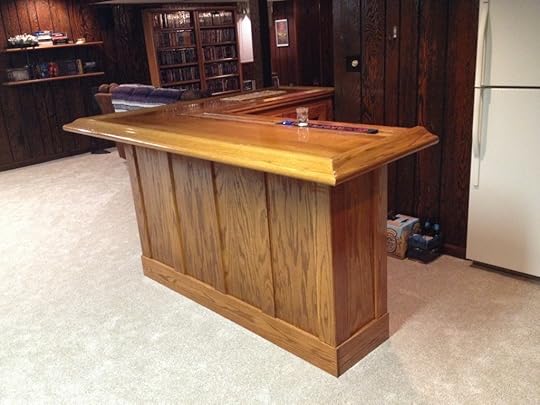

HOW IT ALL BEGAN… A few months ago, my basement had some water damage thanks to a faulty sump pump and all the carpet was removed. Before having new carpet installed, I decided that while the main room was bare concrete floor and empty of furnishings, I would finally take a crack at replacing the old half-bar that had been fashioned out of paneling 30 years ago by the home’s original owner. I wanted a more formal bar that resembled the Irish bars I’ve grown to love writing novels in.

A few months ago, my basement had some water damage thanks to a faulty sump pump and all the carpet was removed. Before having new carpet installed, I decided that while the main room was bare concrete floor and empty of furnishings, I would finally take a crack at replacing the old half-bar that had been fashioned out of paneling 30 years ago by the home’s original owner. I wanted a more formal bar that resembled the Irish bars I’ve grown to love writing novels in.

However… the stores that sell home bars wanted $3,000 – $5,000 for the kind of bar I wanted, and really none of them offered the kind of gorgeous golden oak I loved, even if I could have afforded that kind of price tag. And they wouldn’t have fit the particular space I had very well, given that I had a short wall and a built-in refrigerator I couldn’t completely block.

So I was left with the option of trying to build it myself.

The only problem with that idea was, my experience with woodwork is almost nil. I replaced some plank flooring in a shed once… and helped my stepbrother install a small deck at my first house 20 years ago. That’s about it. I didn’t even have most of the tools I would need. During the course of this project I made a LOT of trips to Menard’s, and ended up buying a new circular saw, miter saw, rechargeable drill, carpenter’s square, nail sinker, tape measure and electric sander, among other things. That certainly inflated my overall pricetag, but I now have a great work bench in my utility room.

I didn’t let little things like lack of knowledge, experience or tools stop me! And you shouldn’t either!

CREATING THE PLAN…

I scoured the Internet for plans and “how-to’s” on home bars and found a few articles and YouTube videos with various approaches. I compared what they did with what I wanted, and found myself coming back again and again to Gordon Milligan’s excellent blog post on how he built his home bar. Emboldened that it might actually be possible for someone completely inexperienced like me to do this, I sat down and planned out the dimensions for what I wanted to do for my own project.

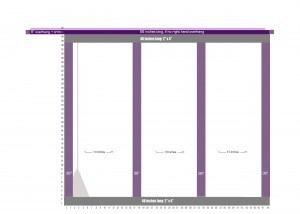

I’m a very visual person, and can’t really deal well with blueprints. I created some initial planning schematics in Photoshop to give me a plan, but I also saw a lot of articles that suggest using boxes or some other three dimensional object to get a feeling for what your “plan” will really feel like in three-dimensional space once it’s done… and I think that’s wise. I already had “half” a bar (the one I was replacing), so I used that — putting it in place first on one side, and then sliding it to the other side of the area where my new L shaped bar would go (the previous bar was simply an I). I chalked out the floor around it so while I had dimensions committed to paper, I would visibly see if something had gone awry from my original plan while I worked. Having a concrete floor at the time and building it in place was definitely a plus.

I’m a very visual person, and can’t really deal well with blueprints. I created some initial planning schematics in Photoshop to give me a plan, but I also saw a lot of articles that suggest using boxes or some other three dimensional object to get a feeling for what your “plan” will really feel like in three-dimensional space once it’s done… and I think that’s wise. I already had “half” a bar (the one I was replacing), so I used that — putting it in place first on one side, and then sliding it to the other side of the area where my new L shaped bar would go (the previous bar was simply an I). I chalked out the floor around it so while I had dimensions committed to paper, I would visibly see if something had gone awry from my original plan while I worked. Having a concrete floor at the time and building it in place was definitely a plus.

BUILDING THE FRAME…

The first step was to build a frame. I’d never framed anything. But looking at Milligan’s post and a couple others, I gradually got the concept of using “squares” of wood that interlock. I opted to use 2 x 4s instead of 2 x 6s, because my bar wasn’t going to be that long — just over 6.5 feet in one direction, and just under 6 feet in the other (measured from the ends of the Chicago bar rail, not the frame itself).

You have to do some math here to arrive at how big to make your frame… because on top of your frame, you’re going to hang wood of a certain dimension (probably 3/4 inch) and then you’re going to want to seat a bar top above that which covers the frame and extends 8-10 inches past your “walls” so people’s knees have somewhere to go. So you need to plan your frame based on the width of your actual bar top as well as on the ultimate final height. You should end up with your bar being about 41″ high.

If you’re doing an L shape bar as I did, you can actually build two sections completely separately, and then press them together at the very end and “latch” them. That’s how some of the pre-fab bars at furniture stores work. But I wanted my bar top to meet at an 45 degree angle and I wanted the whole bar to feel like a solid piece, so my frame is not divisible. That also means, my bar can never be disassembled to easily leave my basement. I pity the man who decides to take it apart someday.

A lot of people build the bar and then build the additional cabinetry as a separate box that sits behind the bar… I decided to frame in the cabinet area right under the bar to make the best use of space, so my frame was deeper than many I’ve seen. One problem I created for myself… In the last picture above, you can see that I made a smaller cabinet on the left (front) face of the bar than on the right. I also made the right side a couple inches deeper than the small cabinet, so I could store more things. This came back to bite me in the end, because that meant that the bar top needed to be extra wide to cover one side vs. the other… the realistic endgame of that is that the overhang on one side is shorter than the other. Nobody would notice really… but it’s a consideration I didn’t consider in planning!

You also have to plan whether your bar top is going to be edged by some rounded finishing pieces or by true Chicago bar rail. My dream was to have a bar that really looked like a pro bar… so Chicago bar rail it was. But that’s an expensive proposition too – about $12 a foot. To me it was worth it… because that edge is what you’re going to look at every time you walk into the room. I ordered six-foot lengths from Hardwoods Inc. and ended up having to order an extra piece because I’d underestimated my spoilage. Cutting that stuff without pro equipment can be challenging! But we’ll get there in a minute.

HANGING ‘CLOTHES’ ON THE FRAME…

After I created my frame, I used oak veneer plywood (3/4″) to cover the front. I didn’t have a solid piece that long, so I tried to cut the two pieces for each in a length that would naturally be covered by my facing slats. I screwed those into the 2 x 4s of the frame, knowing that I would be adding slats later that would cover the screws and the seams. On the inside, I used 1/4 inch oak plywood.

For the top “underside” shelf I used 1″ solid oak, but since I ended up facing it, I really could have saved a couple bucks there and used oak veneer plywood. That’s what I used for the interior shelves. For those, I screwed in 1 x 1 oak strips to serve as my shelf support (again, in retrospect, I could have saved some money and used pine since it’s really not visible). To cut out the front U opening in the shelves that fits around the 2 x 4 central dividers, I clamped the shelves to the top of the bar frame and used a jigsaw to create the U cut. Despite careful measuring, I cut them too tight the first time and had to open up the “hole” a little… but that was better than the reverse problem.

After I had the shelving placed inside, I used 1/4″ oak veneer slats to cover the visible sides of the 2×4 support. These were attached with wood glue and clamps. Then I used 1 x 2 pieces to create a facing lattice on the cabinet insides to hide the seams. These were also glued, with some small finishing nails to hold them in place. I used a nail punch to push the nails deep into the 1/4″ pieces and then covered them with wood filler.

Once the cabinet insides were finished, I could finally add the facing boards on the outside. I used oak 1 x4″ pieces, except for the vertical end pieces which were wider. I wanted everything tight, so I tended to cut them slightly large and then shaved them down a hair at a time on the miter saw until the seams all snugged up well.

THE BIG CUT!

Once the back facing was in place, I began to get the bar top ready. I placed a couple of 1 x 20 x 72″ sanded plywood pieces on top of my frame, and positioned my two 1 x 16 x 72″ oak boards on top of that, and then placed the oak rail in place to see how it all was going to sit once I began cutting things to size.

Once I was sure all of the pieces were going to work, I cut the plywood base for the bar top and screwed that into my frame. Then I cut the oak boards for my bar top… probably in the worst way possible! I didn’t have a table saw, and the miter saw would only cut 12 inches… I needed 16. So I put the two pieces on top of each other in a right angle and clamped them down hard. I also clamped my level — I used it as a metal guide for my saw to move against and stay straight. Then I used my circular saw to free-form cut across the two pieces to make my 45 degree angle cut. A pretty risky proposition with two big expensive pieces of oak. In the end, I got lucky and it worked pretty well… but I didn’t achieve a perfect no gap seam – after sanding, staining and varnish, it looks good, but it’s not as “tight” as a table saw would have gotten it.

Once that most stressful cut was complete, I clamped the oak in position, applied some wood glue to help lock it to the plywood frame beneath it, and then screwed the base and the top together. I drilled small holes on the underside of the bar and then screwed up from beneath (which was difficult in the far ends inside the cabinet!) I used screws short enough that they wouldn’t come through the top of my bar. Once it was screwed so much that it will never, ever, ever come apart, I sanded the top down, especially the area where the 45 degree seam met.

Finally, it was time to do the second most important cuts of the project.

THE BAR RAIL…

Bar rail is a stepped piece of wood, so it’s difficult to cut easily. It’s really important to a) have a good table/miter saw and b) put a spoiler board of the right size under the “step” of the underside of the bar rail. My miter saw turned out not to be a “perfect” angle cutter and I ended up re-cutting my edges several times because I kept ending up with a cut that left the top of the bar rail separated while the bottom was tight. Ultimately I ended up tilting the blade of my miter saw a degree to ensure the bottom of the rail wasn’t stopping the top from closing tight. That’s what you get when you buy a $100 miter saw instead of a pro piece of equipment. But I made it work. Watch this key video on YouTube to see how to do this… I watched it many times!

After I got the bar rails cut, I applied wood glue to the subboard and upper inside “step” of the bar rail. Then I clamped them in place, and drilled holes every few inches on the underside, making sure my screws were going to go through in the deepest section, so they didn’t pop through the top of my rail. It was a wonderful feeling when I took those clamps off the next day and everything was solid and tight!

THE SPILL RAIL…

After screwing the bar rail in place, I cut 1×3 oak boards and made the outside of the spill rail. Because of my shelving, I actually needed a thicker edge than many bars I’ve seen in order to allow my bar top to overhang on the outside of the frame enough, while covering the whole frame too. My actual center oak of the bar was 16″ wide. But with the bar rail and the spill rail, the full depth of my bar from edge to edge is just over 26″.

Basically with my spill trough and its outlying rail, I extended my top by several inches and achieved the coverage over the frame and cabinets that I needed, while providing a useful feature in a basement that would have carpet — while many spill rails are not contained on the inside of the bar, mine is… because you don’t want spills draining onto the carpet, but rather being contained by the spill trough.

I used my existing Makers Mark rubber mat to tell me the right dimension for the trough (3.5 inches). Once I had it all set, I glued and clamped the trough rails in place and screwed them into the support plywood from underneath so no screws show.

I also faced the inside of the trough with 1/4″ oak strips. Originally, I did this to both extend the live surface of the bar a half inch on the bartenders’ side, as well as to provide a slight divider between the bar top and the overflow into the trough. I was going to use an epoxy to finish the top of the bar and I figured that little bump would keep the epoxy contained on the bar so that it didn’t drain into the trough. In the end, I opted to simply varnish the bar, so that plan was unnecessary.

I used the 1/4″ oak veneer strips to cover the bottom of the trough so that you weren’t seeing the plywood that the oak bartop was screwed into. Then I faced the inside rail of the bar with two rounded oak veneer pieces. These gave it a finished look and also helped hide the fact that one side of the inside part of the bar stuck out from the frame slightly more than the other!

I faced the front and side vertical panels of the bar with a 1 x 6″ oak piece on the bottom and .5 x 4″ slats vertically spaced out strategically to hide the seams of my oak face. These were attached with wood glue and a couple small finishing nails to hold them tight while the glue dried since I had no way to clamp them. I sunk the nails below the wood surface and covered them with wood filler. I actually varied the pattern of the slats between the front and the long side, and like how it turned out.

MAKING DOORS WITH WINDOWS…

The final building step was to create the cabinet doors. I wanted the side of the bar that you could see walking into the room faced with doors, while I left the other side open.

I used 1 x 3″ oak strips and miter cut the ends to 45 degree angles. I actually cut them one on top of each other on the miter saw to ensure a matched cut. Then I laid them out on a flat cement floor, glued them and screwed them together. To hide the screws, I faced them with a 1/4″ oak finishing strip that I glued on and clamped. On the inside, I glued quarter round pieces, so that there was an inside “shelf” for the glass to rest on.

I used 1 x 3″ oak strips and miter cut the ends to 45 degree angles. I actually cut them one on top of each other on the miter saw to ensure a matched cut. Then I laid them out on a flat cement floor, glued them and screwed them together. To hide the screws, I faced them with a 1/4″ oak finishing strip that I glued on and clamped. On the inside, I glued quarter round pieces, so that there was an inside “shelf” for the glass to rest on.

I learned the importance of not letting any glue leak out onto visible surfaces with that maneuver — I thought I’d worked pretty clean with the glue, but I ended up with some discolored areas once I applied the stain — you could see where glue had seeped out and soaked into the wood. Luckily I was able to touch up the marks with a Miniwax Stain Marker.

Once assembled, I attached the plexiglass I had had cut to size at our hardware store by screwing it in with screen clip holders. I then removed the plexiglass until after the stain and varnish were done (leaving the holder screws in place) and attached the doors with three hinges each. I set the doors up on blocks to ensure an equal alignment.

THE HOME STRETCH – ADDING COLOR AND SHINE!

Once the doors were on, it was time to sand and stain. I used both a small power sander and sanding sponges to go over all the visible areas. To choose the stain, I bought some stain sample packets at Menard’s and used the scraps of wood from the bar rail and bar front to test what each of our favorite options might look like. I love the honey oak look, but I wanted to make sure this had a little deeper richness to it, so I ended up using Varathane’s Golden Mahogany. I started on the inside so that if I hated it, or made any newbie mistakes, I could hide it. Once I’d completed brushing it on and paper toweling the excess back off, I stood back and looked… and worried that I’d gone too dark.

My wife agreed it looked a little darker than we thought, but urged me to press on… and once it dried, it did lighten just a bit, letting the buttery finish show.

The addition of varnish brought out the golden hue more, and in the end, it looked exactly as I’d hoped!

This was the first time I’d varnished anything in probably 25 years, and when I read the instructions to sand the urethane after each coat, I couldn’t believe it… how counter-productive is that? You put on a paper thin coat and then sand half it back off? But if you want a non-bumpy finish… you have to do it.

I brushed on 5 coats of urethane over the course of 4 days. I used fine sandpaper in between the first couple coats and then began using steel wool. I used a a tack cloth to make sure the dust all came off, however, the first four coats of Miniwax Spar Urethane were full of small remnants – it was as if I was painting the bar with a clear coat that included hundreds of grains of sand. I tried a new can, and got the same result. Finally on the fifth coat, I switched and used Varathane Spar Urethane… and the result was amazing. The urethane went on with a completely different consistency than the Miniwax. It dried to a beautiful, clear almost speckless coat, and I decided that that was as good as it was going to get. I saw some recommendations to do 7 coats, but I stopped at 5. That coat count, by the way, is for the top. I only went over the sides of the bar twice. Those didn’t need to be like glass.

A few days after my final coat, the carpet came… it was a wonderful feeling to move that bar finally into position. It had taken over two months… but I had built a bar!

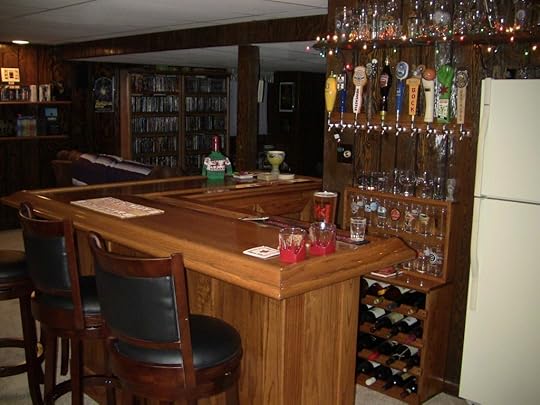

THE TAP DISPLAY…

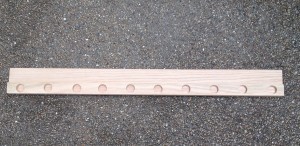

But I wasn’t completely done. I had gotten the idea to create a beer tap display to mount on the wall behind the bar. During the weeks that I was slowly building the bar, I also was searching eBay for the taps of my favorite beer as well as some cheap tap spigots to “mount” my taps on to create an authentic looking display (much as I would have loved to have them, I was not going to run real tap lines through the wall… and then have to clean them every week!). I found some kegerator spigots for about $10 a piece, and one by one, assembled my wish list of taps.

Once I had all my taps and tap spigots ready, I took two pieces of oak and cut them to size. I used a 1 1/8″ spade bit for my drill and bored holes in the top piece with about 2.75″ in between each hole. Then I glued that board to the larger board, stained and urethaned them, and then used Gorilla Glue to lock my spigots into the holes (I tried to find a way that I could screw them into the wood… but that didn’t work. Gorilla Glue locked them in really good – I just had to go sparingly on it, so the push-pull tap action didn’t get locked up when the Gorilla Glue foamed up inside the spigots).

THE BACK BAR…

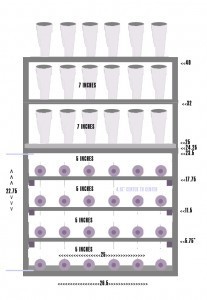

My final project for the bar space was to build a “back bar.” The taps looked a little odd, floating up high on the wall with nothing beneath them, and I had more wine then our small wine rack held. Plus, I had more of my pint glass collection I wanted to display. So I decided to build a combination wine rack / glass holder to fill the space beneath the taps.

I was a little worried about the length of the thing – the wall space between the refrigerator and the bar cabinet doors is not a lot. And I didn’t want to completely block the cabinet from opening. I figured out what seemed like a good compromise and then used wine bottles to gauge how deep the lower half had to be — I didn’t want it to stick out a half inch farther than it had to from the wall! The rest was a fairly simple project after the bar — I framed up a box using oak (again, I could have saved a lot of money on this piece if I’d used mostly pine).

I measured my existing wine rack to decide how much clearance I needed between shelves, and then figured out how many shelves I could have in order to have the top piece of wood end up level with the top of the bar (41″).

I measured my existing wine rack to decide how much clearance I needed between shelves, and then figured out how many shelves I could have in order to have the top piece of wood end up level with the top of the bar (41″).

Most people would do this on paper, but I figured all the measurements out using my grid in Photoshop.

I used 1.5″ and 3″ hole saws on my drill to make the wine bottle holes in the wood, both front and back of shelf pieces (small holesaw on the front and wide on the back.) I used the wine bottles again to figure out how much spacing I wanted between the holes and then clamped two pieces of wood together and drilled out my holes (one piece got the top half of the hole saw, the other piece got the bottom, so I ended u with half circles in each board).

I used small 1 x 1 boards to hold up the shelves, and then drilled and glued the rear bottle supports onto the back of each shelf board. I set those in place and slid them out slightly, so that the front wine bottle holders sat on them… then I drilled holes and attached those to the frame and then slid the shelves back inside. So the end result is, my shelves are removable, if I desire, though they look locked in place. I sunk the screws in below the face of the wood, and put filler over the top. You can see the circles, but they look like rustic wood plugs instead of visible screws.

The top half for the glasses was a very simple box made of 1x4s with a shelf right in the middle of it. I put 1/4 inch oak veneer on the backs of both pieces, and then sanded, stained and varnished them (two coats). After it dried, I brought it to its new home behind the bar, and screwed the top onto the bottom by going up from beneath, so the screws wouldn’t show. It worked out nicely!

And then for the finishing touch — I snaked Christmas rope lights inside the main bar and tacked them in place with some cable holders. Then I added an easy on-off switch at the end of the extension cord and hid them with a bottle on the lower shelf. This really brightened up the bar – there’s nothing like the gleam of colored liquor bottles being backlit!

One thing I wasn’t going to do was build the barstools… but I couldn’t find any that matched the wood of the bar — everything seems to be done in walnut and cherry. And in most of the stores where they sell bar stool and rec room furniture, the prices were $200 and $300 per stool. Ultimately, I found a set at Hobo that worked well – they were cherry, but with black leather and swivel seats. And they were just $80 a chair with backs, and half that for the stools without backs… I bought three “chair” stools for one side and three no-back stools for the other. While they don’t match the bar, they complement it nicely – and they’re comfortable!

It was a long, involved project, one that took up my minimal free time for months… but it was definitely worth doing. It looks great, it’s custom to the space, and every time I walk into the room, something inside me perks up and pounds its invisible chest and says “I did that. Me!” I think I’m more proud of the accomplishment of this project than I am of most of the books I’ve written. Speaking of which… for those of you waiting on the next Everson novel… it’s going to be a bit delayed. I… um… spent a lot of my “writing time” this year building a bar!

Of course, those of you who follow my work probably know that I do a lot of my writing in bars — and now I have a really comfortable one very close to home. So maybe I’ll be more productive this year.

After all, the bartender never calls for my tab!

newest »

newest »

Nice! That turned out great, John!

Nice! That turned out great, John!