Finished… sort of…

C.E. Grundler

It might not be pretty, but in some ways, it’s downright beautiful. In my eyes, it could just as well be the ceiling of the Sistine Chapel. And yet again, it’s another project that, once all is said and done, no one will ever see.

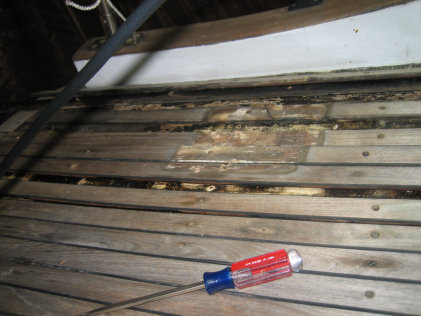

For those who haven’t been following my ongoing trails with the salon ceiling/bridge deck, I’ll recap what brought me to this point. My boat’s previous owner, I was told, was very fond of bright decks, and his preferred method for keeping them bright involved a belt sander. Years of this technique eventually took the teak decks down to the fasteners, at which time planks loosened, and he remedied that by adding larger (and longer) screws, ones that penetrated the fiberglass beneath the teak, and the structural core beneath that fiberglass. Water followed that route, and over years of freezing and thawing, delaminated a large section. Fortunately, that coring was solid teak lumber so there was no rot, but with fiberglass above and below, it remained water-saturated and would perpetually weep into the cabin in the few spots it found an exit.

What this picture doesn’t show is just how delaminated this section is. At first, a few simpler methods were considered, yet due to the extent of the delamination, in the end it came down to removing the entire area of damage, rebuild a new core of marine-grade mahogany ply, laminated in layers to match the original camber, new ribs, and re-glass it in from above and below.

Step one. Remove old teak decking. Not pretty or easy.

Step two. Determine that what lies beneath is beyond repair. Build a new core.

Cut massive hole in boat. (Stiff drinks afterward strongly recommended.)

I can assure you, cutting away large sections of your boat is the stuff of nightmares. Next, forklift replacement core, still on its frame, up to boat. The structure in the cockpit was built to hold it at the proper height so the laminate could be slid into place in the cabin.

New core, lagged into position. From below you can see where epoxy followed the screws used to ‘clamp’ the layers together as they were joined. The screws were removed and the holes filled with thickened epoxy. Lots of sanding ahead, to give those areas of epoxy sufficient tooth to hold the upcoming laminates.

Next, laminate in ribs and filet the edge, (guess I didn’t get any pictures) and then cut fiberglass. Lots of fiberglass. All bagged and numbered in order of layup, because the last thing you want to find yourself doing one epoxy is setting is look for that right piece.

Mix epoxy. Wet out surface. Wait for it to ‘kick’, lay up glass, repeat. Well over 100 pieces, once all was said and done. Once that first round of epoxy is applied, there’s no turning back, and setting resin waits for no one.

And there you have it. Remember, working with the right materials is vital. West Systems are a two-part epoxy, though I do believe a small portion of that third bottle pictured is critical when undertaking work of this sort.

What these photos can’t convey is the countless hours, which stretched into days, weeks, and months, that it took to complete each step. This entire undertaking could make a wonderful tutorial on why one should never wonder what lurks beyond the headliner unless they intend to forge ahead or do their best to ignore the effects of delamination. Neither is a pleasant option. And I do realize that while I’ve been toiling away, these problems and worse exist among the many boats that are happily being operated and enjoyed by their unknowing owners, which goes to show that ignorance truly is bliss. Non-itchy, non-sticky bliss. Unfortunately for me, I’ve always been of the mind that what you don’t know can hurt you. And no, this isn’t over yet. Next, the exterior will be laminated with a mix of mat and biaxial/mat fiberglass. Once all is finished, it should be stronger than the original layup, as well as completely sealed.

Share on Facebook