How Custom Molds Can Bring Your Creative Vision to Life: A Guide for Manufacturers

Do you have a creative vision that you want to bring to life through manufacturing? Custom molds can turn your ideas into reality by allowing you to design and shape products in unique ways. Whether you’re dreaming up a one-of-a-kind object or need precise specifications, any shape custom molds can meet your requirements and bring your concepts to life. The flexibility of custom molds offers endless possibilities for creativity.

Using custom molds in manufacturing allows you to create distinct and complex forms. This method provides the accuracy and personalization needed for specialized projects. Custom molds are your solution if you need products that align with specific design goals. Learning how to create custom molds means you’re not limited to conventional shapes or materials.

Innovative projects in manufacturing often require unique solutions. Custom molds let you experiment with various materials, textures, and finishes, elevating your projects to match your vision. By embracing this process, you’ll find opportunities to stand out in your field or market. Custom molds don’t just make ideas possible; they make them tangible.

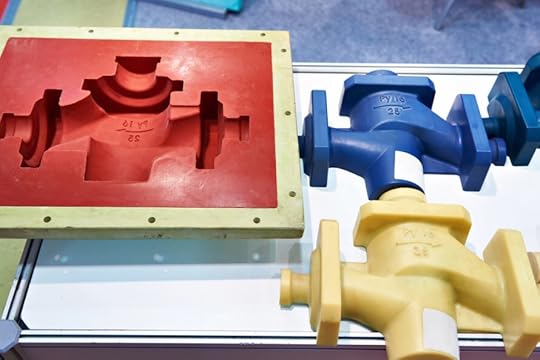

Unleashing Creativity with Custom MoldsCustom molds are important tools in product design and manufacturing. They allow you to create unique designs and turn ideas into real, tangible products. By using advanced molding techniques, you can produce items that precisely match your creative vision.

The Role of Custom Molds in Product DesignIn product design, custom molds give you the chance to bring unique designs to life that might not be possible with standard molds. This can include intricate patterns or unusual shapes that demand specific molding processes. For instance, when designing a new type of soap or making one-of-a-kind sculptures, custom molds offer flexibility and precision. These molds not only help in realizing your vision but also in maintaining consistency across multiple products.

Custom molds are particularly valuable in industries like art, craft, and food production. They allow you to experiment with new designs and create products that stand out in the market. Whether you’re working with polyurethanes in casting resin or designing silicone molds for soap making, the possibilities are a lot.

Transforming Ideas into Tangible ProductsTransforming your creative ideas into tangible products becomes achievable with custom molds. These molds allow you to prototype and test your designs quickly, which can save time and costs in the long run. The process of taking an idea from concept to creation involves using techniques and technologies that make precise molds based on your specific requirements.

By utilizing skilled professionals and the right tools, ideas can be efficiently turned into market-ready products. Advanced tools and techniques help you produce detailed items, whether it’s a new gadget or a decorative item. Industries such as food and toy manufacturing benefit by using plastic molds that unlock innovation, turning visions into practical and sellable products.

Technical Insights in Custom Mold ManufacturingCustom mold manufacturing requires a deep understanding of materials, precise engineering, and cost-effective practices. Each element plays a key role in meeting design specifications and maintaining production efficiency.

Materials and Techniques for Durable MoldsChoosing the right materials for custom molds is important to achieve longevity and durability. Common materials include steel and aluminum, each with unique properties. Steel offers durability and strength, making it suitable for high-volume production. Aluminum, while not as strong as steel, is lightweight and easier to machine, making it ideal for prototypes or short runs.

Advanced techniques such as injection molding and 3D printing are often used to create intricate designs. Injection molding is widely used for its efficiency in creating complex shapes. 3D printing, meanwhile, allows rapid prototyping with detailed precision. Combining these techniques with strong materials results in molds that can withstand repetitive use under various conditions.

Precision Engineering and Quality ControlPrecision engineering is at the heart of custom mold manufacturing. This involves designing each component with exact specifications to meet design goals. Computer-aided design (CAD) software allows engineers to create highly detailed designs that precisely match the intended product. This precision minimizes waste and guarantees uniformity across all produced items.

Quality control methods include regular testing and inspections. These processes help identify potential errors or defects early. Using tools like Coordinate Measuring Machines (CMM), you can accurately measure and verify dimensions. These practices help maintain consistency, reduce errors, and produce end products that meet quality standards.

Cost-Effective Solutions in Mold MakingReducing costs in mold manufacturing without compromising quality is a common goal. One approach is using modular mold systems, which allow for interchangeable parts. This reduces the need for entirely new molds for each different product, saving both time and materials.

Simulating production runs with software can also identify potential problems, allowing adjustments before full-scale manufacturing begins. Outsourcing components to specialized facilities with expertise in certain aspects of molding can bring additional savings. These strategies, when combined, contribute to significant cost reductions while maintaining the integrity and functionality of the mold.

ConclusionCustom molds can be transformative for your creative manufacturing projects. By using custom molds, you can achieve unique and intricate designs that perfectly match your vision.

Working with experienced professionals helps bring detailed designs to life with precision. This approach reduces waste and improves efficiency in the production process, allowing you to produce high-quality products consistently.

With the flexibility offered by custom mold manufacturing, you can push the boundaries of creativity. Tailoring the mold to your design needs provides numerous possibilities for innovation and quality in your work.

The post How Custom Molds Can Bring Your Creative Vision to Life: A Guide for Manufacturers appeared first on Geek Mamas .