Altering a bra for better fit and support

On Twitter, a protracted discussion of the fit and durability of ready-to-wear commercially-made brassieres arose in the comments to someone's exasperated complaint about the fact that all modern bras pretty much fit poorly, regardless of size or material used. Because of the significant positive response to my threaded contribution on bra alteration suggestions, I'm writing up the gist of my thoughts/methods.

First, know that I significantly alter every bra I buy before wearing it in public. (For reference, I wear a 34F--narrow ribcage/large bust--and I've found that Freya brand bras fit me best.) Also, please note that a well-fit bra is a complex structural garment which requires customization for most all body types in order to fit and function at its best, & at present this level of sophisticated structure isn’t found inexpensively/ready-to-wear.

How am I qualified to write this post? I taught a graduate level course in structural undergarment construction last semester, in the costume production MFA program at the University of North Carolina at Chapel Hill. Our graduates typically go on to successful careers as costumers for Broadway, opera, ballet, and A-List film talent. On the bustline front, one of our alumni is Dolly Parton's personal draper, so yeah.

Some of these alterations will be outside the realm of possibility for those who don't own a sewing machine, but some are things you can do with a little determination and a needle and thread.

First up, I stabilize the straps, which is something anyone who can sew a strong sturdy tack by hand could accomplish. Few people have enough monthly deviation in breast size to need adjustable straps. (Sliders just allow a readymade bra to "fit" a wider range of buyers.) Stable straps = better support. Adjust the sliders to where you need them to be, then safety-pin them. Wear the bra for a day or so and see if you have the right length, then stitch it to stabilize.

Second, almost all bra bands need reinforcement. Stability in the band is a major element of fit. How I stabilize the band depends on the bra--sometimes I stitch a stronger piece of elastic in with a serpentine stitch (by machine, domestic machines often have this option on the specialty stitch dial), sometimes I flatline the whole bra band with girdle mesh, either by machine or strong whipstitch by hand. Sometimes I do both. We stock girdle mesh as a standard material at my workplace, but you can buy it by the yard from specialty fabric stores, or cannibalize a girdle for it.

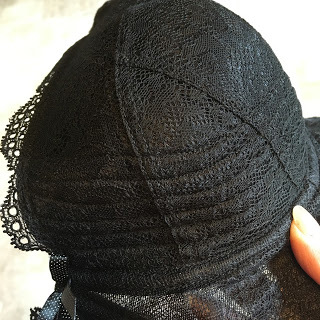

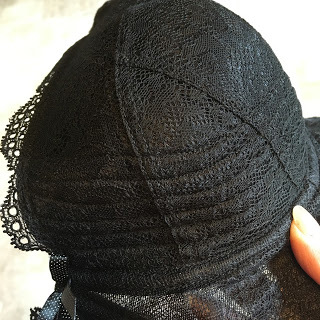

Next, I machine-stitch concentric arcs into the underside of the cups to give more stability and lift. I do 6 rows (see pic) but a smaller cup may only need 3, 4, or 5 rows. These rows of stitches are 1/4”-ish apart following the curve of the underwire, like in these pics:

You might recognize this kind of spiral/concentric stitched cup structure from 1950s bullet-bras and contemporary pin-up photoshoots. That's because this kind of stitching helps buttress the breast for lift and shaping. Nobody has torpedo-boobs naturally, but concentric/spiral stitching on a torpedo-shaped cup helped 1950s women achieve those shapes. You can use that to your advantage for helping a modern bra cup keep its shape, too.

And lastly! Another way to help stability in the band is to add a bone to the side seam. Plastic, Rigilene, spiral steel, flat steel, depends on the size of the bust which is best. As someone with a narrow ribcage and large bust (34F, remember?), I get the best result from 1/2" flat steel bones. This might seem like it will make your bra uncomfortable, but the more structure an undergarment has, the more comfortable and supported I feel. Caveat: I spent ten years of my life wearing a corset to work five hours a day, so YMMV.

And now, textbooks! Want to read some reference titles? Beverly Johnson’s The Bra Maker's Manual and Ann Haggar’s Pattern Cutting for Lingerie, Beachwear, and Leisurewear are the two most relevant to this discussion, and two of the required texts for my class.

Hope this was helpful, and if you have any other recommended bra alterations you like to do, please drop a comment!

First, know that I significantly alter every bra I buy before wearing it in public. (For reference, I wear a 34F--narrow ribcage/large bust--and I've found that Freya brand bras fit me best.) Also, please note that a well-fit bra is a complex structural garment which requires customization for most all body types in order to fit and function at its best, & at present this level of sophisticated structure isn’t found inexpensively/ready-to-wear.

How am I qualified to write this post? I taught a graduate level course in structural undergarment construction last semester, in the costume production MFA program at the University of North Carolina at Chapel Hill. Our graduates typically go on to successful careers as costumers for Broadway, opera, ballet, and A-List film talent. On the bustline front, one of our alumni is Dolly Parton's personal draper, so yeah.

Some of these alterations will be outside the realm of possibility for those who don't own a sewing machine, but some are things you can do with a little determination and a needle and thread.

First up, I stabilize the straps, which is something anyone who can sew a strong sturdy tack by hand could accomplish. Few people have enough monthly deviation in breast size to need adjustable straps. (Sliders just allow a readymade bra to "fit" a wider range of buyers.) Stable straps = better support. Adjust the sliders to where you need them to be, then safety-pin them. Wear the bra for a day or so and see if you have the right length, then stitch it to stabilize.

Second, almost all bra bands need reinforcement. Stability in the band is a major element of fit. How I stabilize the band depends on the bra--sometimes I stitch a stronger piece of elastic in with a serpentine stitch (by machine, domestic machines often have this option on the specialty stitch dial), sometimes I flatline the whole bra band with girdle mesh, either by machine or strong whipstitch by hand. Sometimes I do both. We stock girdle mesh as a standard material at my workplace, but you can buy it by the yard from specialty fabric stores, or cannibalize a girdle for it.

Next, I machine-stitch concentric arcs into the underside of the cups to give more stability and lift. I do 6 rows (see pic) but a smaller cup may only need 3, 4, or 5 rows. These rows of stitches are 1/4”-ish apart following the curve of the underwire, like in these pics:

You might recognize this kind of spiral/concentric stitched cup structure from 1950s bullet-bras and contemporary pin-up photoshoots. That's because this kind of stitching helps buttress the breast for lift and shaping. Nobody has torpedo-boobs naturally, but concentric/spiral stitching on a torpedo-shaped cup helped 1950s women achieve those shapes. You can use that to your advantage for helping a modern bra cup keep its shape, too.

And lastly! Another way to help stability in the band is to add a bone to the side seam. Plastic, Rigilene, spiral steel, flat steel, depends on the size of the bust which is best. As someone with a narrow ribcage and large bust (34F, remember?), I get the best result from 1/2" flat steel bones. This might seem like it will make your bra uncomfortable, but the more structure an undergarment has, the more comfortable and supported I feel. Caveat: I spent ten years of my life wearing a corset to work five hours a day, so YMMV.

And now, textbooks! Want to read some reference titles? Beverly Johnson’s The Bra Maker's Manual and Ann Haggar’s Pattern Cutting for Lingerie, Beachwear, and Leisurewear are the two most relevant to this discussion, and two of the required texts for my class.

Hope this was helpful, and if you have any other recommended bra alterations you like to do, please drop a comment!

Published on April 02, 2018 13:30

No comments have been added yet.

La Bricoleuse aggregate and more...

I may crosspost from a couple different blogs on here.

Right now, this space streams the RSS feed from La Bricoleuse, the blog of technical writing on costume craft artisanship that i've written since I may crosspost from a couple different blogs on here.

Right now, this space streams the RSS feed from La Bricoleuse, the blog of technical writing on costume craft artisanship that i've written since 2006, so that may be all you see at any given time. ...more

Right now, this space streams the RSS feed from La Bricoleuse, the blog of technical writing on costume craft artisanship that i've written since I may crosspost from a couple different blogs on here.

Right now, this space streams the RSS feed from La Bricoleuse, the blog of technical writing on costume craft artisanship that i've written since 2006, so that may be all you see at any given time. ...more

- Rachel E. Pollock's profile

- 80 followers