Beth Smith's Blog, page 14

November 1, 2017

Tape Loom Please

So there’s a thing called NaBloPoMo. It’s where you write a blog post every day for the whole month of November. My friend Kat talked me into it with very little pressure.

So, my first post of this month is about something I’ve been thinking about for a long time and then when I was at MAFA in July it was brought to the front of my brain and hasn’t yet receded to the back so I’m putting this out there because I need a little help.

I want to weave tiny bands and so I’m looking for a tape loom. I’d really like an old one but I did find this website with these quality modern ones. But if you have a lovely old tape loom hanging around your house and you dying have a use for it please let me know.

If you aren’t sure what a tape loom is look at these photos.

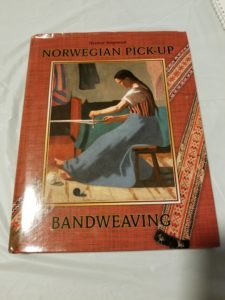

I’m also in the market for these books:

I figure if I’ve been thinking about this regularly for the last 3 months I’d better do something about it. Feel free to talk to me about your tape loom weaving adventures.

Today I’m driving back to Michigan from Ashville, NC. It’s a long drive. But I have so much to share when I get home.

October 26, 2017

I’m a Little Judgy

Today I teach my first class of 5 total at The Southeastern Animal Fiber Fair or SAFF for short. Today’s class is a breeds study that I started teaching a couple of years ago called Who’s the Fairest: A Princess Breeds study. We all wear tiaras and there is some talk about princesses and how each breed that we will touch compares with a princess’s personality. But, as with all of my classes, there are some things that I want people to come away from class with. First and foremost I want the students to see that there is a use for every wool. That Merino is not the be all and end all. Second, I want them to see that all wool can be used and so I often purposely stick a fleece in there that is full of vegetable matter. Not that those are the fleeces I choose when I am paying a good amount but I am not averse to a little hay and stuff if the price is right.

breeds study that I started teaching a couple of years ago called Who’s the Fairest: A Princess Breeds study. We all wear tiaras and there is some talk about princesses and how each breed that we will touch compares with a princess’s personality. But, as with all of my classes, there are some things that I want people to come away from class with. First and foremost I want the students to see that there is a use for every wool. That Merino is not the be all and end all. Second, I want them to see that all wool can be used and so I often purposely stick a fleece in there that is full of vegetable matter. Not that those are the fleeces I choose when I am paying a good amount but I am not averse to a little hay and stuff if the price is right.

Tomorrow in addition to teaching I get to judge the wool fleece competition. Last year was my first year judging at SAFF and I loved it – even though I was super nervous about it. My experience is as a handspinner and so those are the eyes I use when I judge. It’s hours of me talking about fleece and sniffing them and rubbing them on my face. It’s hours of me getting to do what I love which is appreciating wool in all its many types. Last year’s best in show was a surprise to the winner I think but that Gulf Coast fleece was one I would have wanted to spin and keep for myself. I thought it was a very beautiful example of the breed even though it’s hard to categorize the breed into the categories available.

Then on Saturday morning I’m going to be teaching some students about judging for themselves in the fleece barn. We will go in there and choose some fleeces. I’ll talk about what I stay away from and how I make decisions about the fleeces I buy for my own personal use. Then I’ll help them choose fleeces for a project they have in mind or an imaginary project that they may want to spin for in the future. It’s a super fun class to teach and I love helping people make the best choice without fear.

Then on Saturday morning I’m going to be teaching some students about judging for themselves in the fleece barn. We will go in there and choose some fleeces. I’ll talk about what I stay away from and how I make decisions about the fleeces I buy for my own personal use. Then I’ll help them choose fleeces for a project they have in mind or an imaginary project that they may want to spin for in the future. It’s a super fun class to teach and I love helping people make the best choice without fear.

The other classes are just as fun but a little less judgemental (Getting Even -spinning for more consistency and Woolen Style – making woolen preparations. But they are also great fun.

I’m hoping that by the end of the weekend I will have helped lots of students learn to be as judgy as I am.

If you’d like to have me come and teach for your shop or guild or you want to get a group together I’m always happy to talk about it. I have a wide variety of classes I teach and I’m also willing to develop something just for you.

Don’t forget to sign up for my newsletter. New things are afoot and there will be some exclusive things in the newsletter that you won’t see on the blog. Just scroll down to the bottom of the page and the sign up is right there. Also, I’d love to make it personal for you so please put in your first and last name. Thank you so much!

October 19, 2017

Changes….just a little, or maybe a lot.

I’m in the midst of changing some things. Some of them I’m not ready to tell anyone about yet. But I’m working on some new things and I thought I’d let you know.

I can tell you that I’m adding some new classes and taking away some of my offerings that I think are a little tired or less popular to make room for new ones. And, this may not surprise you, but several of the new classes will be about weaving and spinning for weaving. Stay tuned for those updates. Some of those classes may take a few more months to get fully ready because I need to make some samples for classes and also work through them to make sure the timing will work.

If you’ve taken classes with me, you probably know I like to pack a lot into a class so I am making sure that I’m not over packing so we can actually do the work in the time allotted.

I’m working on a bit of a retreat thingy that is going to be super fun, super awesome, super small and very personal for the lucky few who can attend.

I’m working on honing some skills which required me to get this beauty off the shelf. I bought this camera in 2013 to take pictures for the Spinning Loft online store. I never really learned how to use it correctly but it does take a good photo. I probably haven’t touched it since 2015. I’ll never be a professional but I would like my photos to look a little better.

me to get this beauty off the shelf. I bought this camera in 2013 to take pictures for the Spinning Loft online store. I never really learned how to use it correctly but it does take a good photo. I probably haven’t touched it since 2015. I’ll never be a professional but I would like my photos to look a little better.

With some advice from my friend Kat I ordered a new lense which may serve me better for the kinds of pictures I want to take. I’m crossing my fingers.

If you have a minute, check out Kat’s blog. It’s lovely and airy and inspiring.

Keep watching for the new stuff and if you want to be the first to know about what’s coming, I’m working on a newsletter – yes, another new thing. I’ve had the link to sign up for my newsletter for years but just haven’t done anything about it. now’s the time. So sign up. I promise it won’t be overwhelming or fill up your inbox. The sign up is right here on my home page on the bottom right side.

Now you are wondering, with all of the newness I just told what could I possibly be holding back. Well, stay tuned…or sign up for the newsletter!

October 12, 2017

In which it all turns out alright in the end.

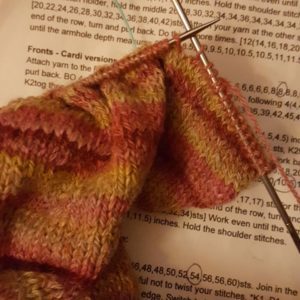

In January of 2012 I made some yarn from wool that was dyed by Amy King. I told Amy I had some yarn for a sweater and couldn’t find a sweater that I wanted to knit with it. I told her the particulars and she kindly designed a sweater to my specifications for me to knit. The yarn is made from a BFL/Silk blend. Spun with a short forward draw and chain plied.

was dyed by Amy King. I told Amy I had some yarn for a sweater and couldn’t find a sweater that I wanted to knit with it. I told her the particulars and she kindly designed a sweater to my specifications for me to knit. The yarn is made from a BFL/Silk blend. Spun with a short forward draw and chain plied.

In December I began to knit the sweater.

I am not a fast knitter and for the last several years I haven’t been very dedicated to knitting projects as I have been distracted by my loom. That doesn’t matter because I need sweaters and I keep wearing out the few that I have that I wear all the time.

So, I would put this project down and pick  it up and time would go by and progress was slow. Like seriously slow. In 2015 I finished the body but I didn’t understand some instruction or other and so instead of asking Amy (who I talk to regularly) I threw it in the corner for a while.

it up and time would go by and progress was slow. Like seriously slow. In 2015 I finished the body but I didn’t understand some instruction or other and so instead of asking Amy (who I talk to regularly) I threw it in the corner for a while.

I know it’s a bad picture but it’s all I have. But you can see it just needs sleeves and button bands.

The problem is at this point I tried it on and so, in addition to having a little issue with my comprehension, I thought it didn’t look very nice on. But that could have been because of stitch holders and stuff.

Anyway in 2016 I finally asked for help and it all made sense. Sleeves were added. I tried it on again.

Not beautiful. The hemline hit me right at my widest spot. It was not cute. So again, the thing went into the bag and into the corner.

Lucky for me, Amy and I were teaching at MAFA together this [ast July so I brought it along to show her. She thought I was just being hard on myself. When I put it  on for her we all were in agreement that something needed to be done.

on for her we all were in agreement that something needed to be done.

Let me just say here that this project pushed me to my knitting limits. I’m generally a pattern follower and this was not complete step by step instructions because Amy assumes that I know things. I had to use some common sense and also be brave and try some things.

I had a sweater with me that I love and wear a lot. It’s waist length and I think it’s pretty flattering so we decided to go with

that. This was again pretty scary. I picked up stitches at the length I thought I needed and snipped a thread and removed the bottom of the sweater.

As soon as the bottom was removed I started knitting ribbing with the yarn from the bottom that was cut off.

You would think that that would be the end of the story, right? Nope, I got nervous about the button band and ribbing around the neck and about shaping and how many stitches to pick up and how the heck to make a good button hole….

So 2 more months went by while I gathered my courage.

It was good and cute. I had bought several different buttons to try. And with my lack of button hole making knowledge I just went ahead so that narrowed my choices for me.

to try. And with my lack of button hole making knowledge I just went ahead so that narrowed my choices for me.

In the end I have lots of yarn left over and some cute buttons to use on another project. I think I need to get spinning for something other than weaving.

By the way, if you aren’t familiar with Amy and her work you can check her out at her store website and her blog.

August 30, 2017

2018 – I Love to Teach

It’s August and I’ve begun thinking about next  year’s calendar. I have some

year’s calendar. I have some

space available if you want me to come and teach at your guild or your shop or your house for you and our friends. Drop me an email or a message and let me know and we can start planning!

In case you’re wondering I have a pretty extensive list of classes available. The classes range from 90 minutes to super in depth 3 to 5 day intensives. Beginning classes to advanced and even some weaving thrown in for good measure. And if there is something your group is eager to learn I’m happy to develop a class just for you.

One of the benefits of hiring me is that I bring my tiara case wherever I go and everyone is welcome to try them on. In addition, if you choose a princess breeds study you can have a tiny tiara of your very own.

So, to recap, if you are looking for a teacher for your guild, shop or group for 2018 I’m your girl.

August 18, 2017

Handcarding – Speeding up

I showed some Tunis on Facebook and Instagram a week or so ago that I had hand carded. I began with slightly over 2 pounds of scoured fleece and it took a little under 4 hours and I had just a tad under 2 pounds of hand carded rolags.

I had plenty of comments about how that was super fast and how some people thought they couldn’t get that much done in that short time. Well I thought a lot about it and here’s what I came up with.

First, hand carding takes a bit of practice. You need to find your most comfortable style. I took classes from several different teachers when I was learning to card and for the first little while I didn’t like carding. It hurt my wrists, it took a long time, my rolags looked like a rat’s nest, and so on. But I didn’t give up. As I kept trying I started to combine things from different insructors and found a way to hold the cards that worked for me and found a way to move the cards that worked for me and found a way to make a rolag that worked for me. And now I can spend two to three hours carding and nothing hurts and I get plenty done.

Here is a Youtube video about my carding method.

Second, I usually am carding raw fleece. I don’t do a lot of fiber blending but when I do, that takes more time. I also choose to card wool that is 4 inches or less. Longer than 4 inches and it’s more difficult and takes more time so I often comb that.

Third, many people do way more passes than I do. 2 to three passes on raw fleece is generally sufficient. Two is the goal. Once you get beyond three you add more chance of getting noils and neps and more lumpy bits. Carding is for opening the locks and aligning everything, and two passes gets that job done. Unless….

Fourth, many people overload their cards. If seems like if you put more wool on your cards you’ll get through it faster but it doesn’t work that way. More wool on the cards means more passes to get everything open. It also means messy rolags that are harder to spin.

Fifth, Netflix or Hulu or Amazon Prime are great distractions and keep me moving when I’m working for a long time on a repetitive task:-) Yes, Netflix, I’m still watching!

August 3, 2017

Endings, New Beginnings and Even More Questions (as usual)

Here is the summing up of the whole Blue Faced Leicester Dress process.

I began spinning this yarn in January of 2016. The intention was another skirt with 2 ply warp and weft but things changed and morphed over the whole time. Mostly because there is a lot of time to think while you spin. Also because some new questions pop up. And also because of laziness which led to the decision to weave with singles which I don’t regret at all.

2 Ply Warp yardage spun – 9188 yards

2 Ply warp grist – 3077 yards per pound

Singles Weft spun – 4500

2 Ply warp was about 20 wpi and sett at 24 epi on the loom.

There were an average of 14 picks per inch

Yardage off the loom – 12.5 yards

Yardage after finishing – about 12.0 yards

Percent shrinkage in length – 3.35%

Total Project time including sewing – 18 months (although there were some weeks in there where the project just sat while I prepared for teaching or writing happened.

I had my mom do the making of the dress because I am terrible at fitting myself. That’s a class I want to take and I am hunting for a good one.

I wasn’t afraid of the cutting and neither was she. I’ve been watching her sew for other people  professionally for years so I knew my fabric was in good hands. We used a Vogue pattern 8997. The sleeve options weren’t my favorite so we took sleeves from another pattern and made them work. The first time wasn’t right so mom just chopped off part of the sleeve cap and all was well.

professionally for years so I knew my fabric was in good hands. We used a Vogue pattern 8997. The sleeve options weren’t my favorite so we took sleeves from another pattern and made them work. The first time wasn’t right so mom just chopped off part of the sleeve cap and all was well.

It took her a total of 12 hours from the time she made the first cut into the bodice muslin until the hemming was done. It was a lot of work but worth it.

Pink lining.

And pink hem tape. It’s those little hidden details that make a custom dress worth while I think.

So the dress is done. And it’s lovely. It has a fantastic drape. The skirt is swingy. The only regret is that I didn’t have silk to line it with and we didn’t have time to make a trip to Philadelphia to get the good fabric so a super slinky, slippery polyester is the lining which makes it a little warmer than I’d like. The next one will have silk lining.

Mom also made me a matching bag!

So, what’s next? Targhee for now. Singles. Experiments with different amounts of twist. Experiments with sizing. The fleece is already scoured. Woolen first but I’ll probably want to compare worsted spun Targhee singles.

I’ll try to post more but if I don’t you can get little snippets by following me on Facebook at my professional page – Beth Smith, my personal page – Beth Shearer Smith, or on Instagram where I’m Threesheeps

July 14, 2017

Personal Classes

If you follow my Instagram and/or Facebook pages you probably know that the Blue Faced Leicester fabric is finished and ready for sewing. The new dress will happen next week so I’ll hold off on doing a recap of the whole project until the dress is finished and I can show you.

In the mean time I wanted to go public with a new thing I’ve been planning.

News!

People often ask me if I do private classes and I haven’t been but a few months ago I started to think about it and decided why not? So today I updated the classes page on my website with the Personal Classes option.

Here’s how it works: You can come by your self or with some friends. Five people maximum. You can spend anywhere from 2 to 5 days with me. Keep in mind that Sundays are out. But any of the other 6 days of the week are free and clear as long as I’m in town. All of the classes will take place in my home so there is easy access to wool, spinning wheels, processing tools and anything else we might want to play with.

Here’s how it works: You can come by your self or with some friends. Five people maximum. You can spend anywhere from 2 to 5 days with me. Keep in mind that Sundays are out. But any of the other 6 days of the week are free and clear as long as I’m in town. All of the classes will take place in my home so there is easy access to wool, spinning wheels, processing tools and anything else we might want to play with.

There is a daily rate which includes materials, my time, the use of any of my tools and lunch!

I have put some sample classes on the classes page and how many days those classes would require. I am planning to add some classes for spinning to weave. If you would like to build your own seminar I am happy to send my full class list and work with you to make the retreat you’ve been dreaming of.

There are plenty of local hotels and the Detroit, Flint, and Lansing airports are all within 45 minute to an hour of Howell, Michigan where I live.

If this is something you might be interested in, grab your friends and let’s get planning. I have plenty of availability in 2018 so let’s fill up my calendar!

June 12, 2017

Skirt Project – Blue Faced Leicester Sampling

It seems like it’s been ages since I have done a blog post and I suppose it has. I’ve been super busy and trying to figure some things out with this current skirt.

So, let me bring you up to speed if you haven’t been following along.

This skirt will be Blue Faced Leicester spun from top that I bought from Spunky Eclectic in the Calypso colorway. The last fabrics were slightly heavier than I wanted. Well, they are great for winter skirts but much too warm for year round wear. My ultimate goal is fabric about the weight of wool suiting. I expect I’ll get there by the time I’m seventy…

This skirt will be Blue Faced Leicester spun from top that I bought from Spunky Eclectic in the Calypso colorway. The last fabrics were slightly heavier than I wanted. Well, they are great for winter skirts but much too warm for year round wear. My ultimate goal is fabric about the weight of wool suiting. I expect I’ll get there by the time I’m seventy…

Anyway, This skirt started as one idea and has changed over the time I was spinning the yarn. The reason for the change is the same reason this project keeps morphing; I keep asking questions and need answ ers.

ers.

So, I decided in the midst of the spinning that I wanted to use singles for the weft rather than the 2 ply I had originally planned. The thing about the singles was that I wasn’t sure how to finish the singles before weaving with them and so I needed to do some sampling.

I had just under 9000 yards of 2 ply yarn already spun so I was ready to go. (If you’re wondering, the 2 ply is about 3100 yards per pound).

The singles for the weft are all still on bobbins so I’m not sure exactly how many yards of singles I have but I still have about 8 ounces of fiber that can be spun. Th

The original plan was to make a 36 inch wide fabric that was 10 yards on the loom but I knew I needed to do some sampling. To avoid having to spin thousands more yards of 2 ply I decided to change the skirt design to be similar to the first 2 skirts – a six gore skirt. That cuts down on the width of fabric needed.

I put a 15 yard 2 ply warp on the loom that was 24 inches wide. The 2 ply yarn was approximately 21 wraps per inch and I sett it at 24 epi. (The last skirts were about 18wpi two ply sett at 20 epi.)

I used yarn right off the bobbin with no finishing.

I wound yarn onto a PVC niddy noddy and soaked the yarn on the niddy and let it dry so it was blocked.

I wound the yarn onto a niddy but then removed it from the niddy and soaked it relaxed and allowed it to dry in that relaxed state.

I used 2 ply as weft for one of the samples for comparison with the singles samples.

So, I made the samples and I finished them by soaking them for about 15 minutes in hot water with a bit of Soak Wash. After they soaked I turned on the agitator and checked the samples after 5 minutes and then allowed them to agitate for another 5 minutes – 10 minutes total.

After the soak and agitation, I let the water spin out and I put the samples in the dryer with a towel for 5 minutes. I removed them from the dryer and they were still a bit damp. I pressed the samples with a hot iron until they were pretty dry. I laid them flat to dry the rest of the way.

And now it’s time to make a decision. I have photos and I’ll try to describe how they feel. Although I wish you all could come and touch them..

The photo above is from the singles that were not finished in any way before weaving. The left sample is the unfinished/right off the loom fabric and the one on the right is the finished fabric. The photo shows a bit of tracking but that isn’t obvious when you look at it in person. The hand is nice and drapey even though this on was a bit stiff or firm with very little drape. The measurements of this sample before finishing was 12″x11.75″. After finishing it is 11.5″x10.5″. There was a lot of shrinkage on this sample which I definitely expected because the weft was not preshrunk by soaking or washing.

This sample is the one that was woven with the blocked singles. The unfinished fabric is less stiff than the one from the yarn right off the bobbin but the hand of the finished fabric is very similar to the last. The original size of this sample was 14″x11.5″ with the size after finishing being 13″x10.25″ So it has about the same shrinkage as the yarn directly off the bobbin. This makes sense logically.

This sample is the one that was woven with the yarn that was washed and then allowed to dry in its relaxed state. This sample showed a lot of tracking on the whole width and length of the fabric. This is not the look I’m going for in this project but It’s interesting to see it and know that if I wanted a fabric with some added texture this might be a good choice for weaving. It’s also a bit fuzzier and has less drape. The original sample was 11″x11″ and the finshed piece is 10″x10.25″. So less shrinkage than the first two but it isn’t the fabric that I’m looking for.

Just for the sake of science I’ll show the 2 ply weft sample:

This fabric is lovely, no tracking at all. The original measurements were 12″x9.5″ and the finished measurement was 11.25″x9.25″. Definitely less shrinkage. It feels a bit thicker which makes sense and has a bit less drape than the samples with the singles weft.

Let me know what you would do but I’m thinking that weaving with yarn right off the bobbin is going to be the choice. It will be less work than the samples with the washed yarns and it gives a lovely fabric even though there is plenty of shrinkage.

The loom is sett at 24″ wide total and with draw in after weaving is about 22.5 inches before finishing. So I can probably plan on at least a 20.5 inch wide finished fabric to use for my project. And because I made samples smaller than the original plan I think I will have at least 11 yards of fabric after finishing. I wonder if that’s enough for a dress…short sleeves of course.

I’m excited to hear what you think….

February 8, 2017

Weaving Decisions

Last time I posted I was looking for your advice and opinions and I sort of knew what would happen before I posted but I was in denial.

What happened was that I got a whole bunch of opinions about how to proceed but nobody mentioned that they knew what would happen because they had done all of the experiments and compared them and they had results. I know that some of the answers were from experience but I’m not sure that they were from fabric that was being woven for yardage for a garment. The sett will be pretty close on this project and I wonder how that affects the results.

What happened was that I got a whole bunch of opinions about how to proceed but nobody mentioned that they knew what would happen because they had done all of the experiments and compared them and they had results. I know that some of the answers were from experience but I’m not sure that they were from fabric that was being woven for yardage for a garment. The sett will be pretty close on this project and I wonder how that affects the results.

One problem with all of this is that every time I feel like I’m making forward progress or get the answer to a question, there are 5 new questions that need 20 samples made to get the answer. But let’s pretend I don’t have new questions and follow through on what the plan is for this particular skirt.

After much hemming and hawing and a little conversation with Sara Lamb, I’ve decided to change the plan.

The original plan was to make a lovely skirt that has lacing on the hip as a closure, a lovely ruffle around the bottom edge and also a bottom edge that is a bit longer in the back. Last fall I took the pattern for that skirt that had been made for me by my mom and laid it out on muslin to see how much fabric I would need for the skirt and how wide I would need the finished fabric to be. The result was I needed to weave at 36 inches wide (the full width of my Mighty Wolf) and I needed just under 7 yards. I was going to dress the loom with 10 yards to take into account the loom waste and a little sampling I wanted to do.

The new plan is a bit more complicated.

Remember, I was wondering how to finish the singles yarn I was going to use for weft and I had several options I was considering:

No finishing at all – use the yarn right off of the bobbins on which it was spun.

Blocked on a pvc niddy.

washed and dried with no blocking

I actually have added one more option in which I wash the yarn and then smack it around a bit to full it and make the yarn a little stronger.

That’s 4 different options and I really do need to see what the affects of each will be.

So now, the new plan is a bit more involved. I’ve reworked my numbers. I’m going to warp the loom with 15 yards. The width on the loom will be 24 inches. I’m going to make 4 samples with the 4 different finishes. each sample will be 48 inches long so that I can cut it in half and finish one half the way I would finish the fabric and the other half will remain in its just off the loom state. It’s good to do that so you can see what changed in the finishing instead of trying to remember.

After all of the samples have been washed and fulled a bit I can make a decision about the fabric.

So, I have 15 yards. I lose about one yard to loom waste. I lose about 5 yards to the samples and so now I’m left with probably just under 9 yards after I tied on again. I think 8.5 yards of 21 inch wide fabric (allowing for some shrinkage in weaving and finishing) should be enough for a knee length gored skirt. I hope.

So, I have 15 yards. I lose about one yard to loom waste. I lose about 5 yards to the samples and so now I’m left with probably just under 9 yards after I tied on again. I think 8.5 yards of 21 inch wide fabric (allowing for some shrinkage in weaving and finishing) should be enough for a knee length gored skirt. I hope.

All discussion is welcome!