Evelyn Tan's Blog, page 3

September 3, 2020

Book Release with two free gifts : -7 Essentials in Supplier Quality Management

August 20, 2020

Is Quality free - Do not shed a tear until they see the coffin

In my previous article, we already know the 3 main reasons why quality is not free which are all related to design.

In the past most of the manufacturing processes are very much dependant on human where most of the defect have direct cause are human error, therefore emphasis on “do it right the first time” was focused on the manufacturing process.

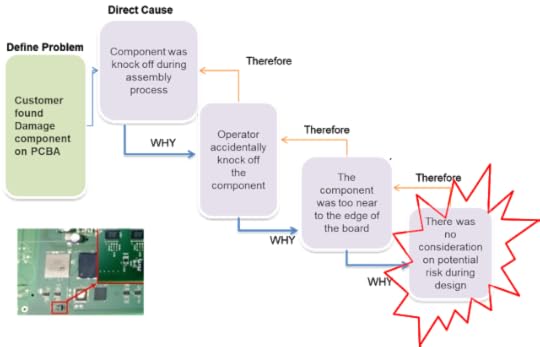

If a further root cause analysis is done, the final cause is actually due to design per the example below.

A simple example would be doing a 5 why analysis

From the figure above, it seems that the manufacturing cause is the cause of the component damage when we deep dive the root cause is pointed to the design issue where the component is designed too near to the edge of the board and cause handling damage.

This will increase the cost of manufacturing due to extra control, rework, more inspection and risk of shipping defect to customer.

We can move towards quality is free by understanding how to prevent or minimize the 4 types of quality cost

Category

Description

Suggested Mitigation Plan

Appraisal cost

Cost of performing test and inspection on a product to screen out potential defect include inspector.

· Create testing which replicate customer environment

Internal failure cost

Cost of rework or scrapped product which does not comply to the spec

· Product design that are error proof

External failure cost

Cost of poor quality at customer site which involve warranty cost, product recall, lost of customer trust

· Plan in quality per prevention cost plan, then quality is really free

Prevention cost

Cost of preventing a defect through quality planning of design in quality and build in quality

· Ensure quality function gets involved during the early design stage

· Benchmark on predecessor product if any to correct the problem

· Proper FMEA involve all downstream function such as production and customer quality

· Study how product being used in customer environment and design the part for customer convenience

From the table above, it is shown that by focusing on preventive cost through proper quality planning would have minimized the appraisal cost and even eliminate failure cost. Bear in mind quality issues design stage will on 1/1000 of the failure cost at the customer site.

Unfortunately, many organizations choose not to put in effort in quality planning during the design stage and hope the problem will never surface during manufacturing or customer site. The management mindset does not shed a tear until they see the coffin (不見棺材不落淚 ) had caused them to pay for enormous quality cost especially if failure happens at customer integration.

August 6, 2020

Is quality Free - What are the reasons prevent quality from being free?

Many years ago Philip B, Crosby a famous quality guru wrote a book title "Quality is Free" where he advocates for do it right the first time in the manufacturing process.

To understand the concept of quality is free, we have to know what are the four categories cost of quality to understand the concept of quality is free per table below:-

Category

Description

Appraisal cost

Cost of performing test and inspection on a product to screen out potential defect include inspector

Internal failure cost

Cost of rework or scrapped product which does not comply to the spec

External failure cost

Cost of poor quality at customer site which involve warranty cost, product recall, lost of customer trust

Prevention cost

Cost of preventing a defect through quality planning of design in quality and build in quality

Among all the four components of quality cost, most organization pay the least attention to the prevention cost. Zero defect product does not happen by chance as there are many errors which could happen to throughout the product life cycle from birth to grave. A very prevalent example that very little attention is being given on quality planning during the design phase would be a software product where there are always patches to correct the program. I am sure all computer user would experience this all the time.

Often organizations only think that do it right the first time is only applicable during the manufacturing of the product to achieve quality is free.

They are ignorant that product design is the main culprit of the cost of poor quality until it is too late.

Many organization will never achieve quality is free due to 3 main reasons:-

1. No attention is given to quality during the early design stage

Throughout concept/design till validation phase, design and marketing team only focus on what is special innovation which will delight customer and customer is willing to pay for it. The normal design approach would be over the wall with little or no collaboration at all with another cross-functional team. This mean quality planning is neglected. During the production phase only quality control of inspection/test to filter out the non-conforming product during production which results in the high appraisal, internal failure cost and expensive external failure cost. It is a ripple effect when there is no investment being made in prevention cost will subsequently result in other 3 quality cost.

2. Unable to surface potential quality problem

The quality issue is always hidden and will only visible under certain circumstances. Most quality problems happen at customer integration as

there was a limited user interface study being done on how a customer could use or integrate into the macro environment.

Another concealed quality problem would be there are not enough sample which represents the population to test out whole range spec.

DFMEA and PFMEA which unable to cover all aspect of a potential problem. A good FMEA requires team member who specializes in quality engineering.

3. Short time to market

This is the most classic reason where organization always push for a product launch at the shortest time without taking into account where adequate testing and planning.

Interested to know what does it take to achieve “quality is free”. More in an upcoming article.

June 15, 2020

Zero-defect a Myth or a reality – Design For Manufacturability

Design for manufacturability is a must to achieve a zero-defect product where the principle in DFM must be followed. Some of the major DFM principles are:-

Design with least part to reduce supplier chain and manufacturing process complexityDesign product which is simple to make Consider the availability of raw materials which use design for manufacturability strategy.

The world is haunted by poor design product especially in some traditional industry where the product life cycle is more than 30 years such as industrial equipment and aerospace where those products are designed without design for manufacturability principle. Unfortunately, most of these companies esp. those big multinational companies choose not to acknowledge the poor design of their product.

The main reason could be political where a large investment had to make and could cause the shareholder to be unhappy with huge investment make to redesign the product.

To work towards zero defect, there must be rigour and quality awareness throughout the supply chain from the transformation of raw material to piece part, subassembly and final product. This includes the followings:

Product design for manufacturability Product design for simplicityA systematic approach to supplier quality management through 7 essential areas (http://www.7esupplierquality.com/)Control of process input according to what had been discussed in this websiteAccurate data analysis to understand what contributed to the defectUnderstand the variation throughout the supply chain

I am sure if all the 6 steps are following through, working towards a zero-defect should become a reality.

June 5, 2020

Zero defect a Myth or a reality - Organization accountability

In a normal situation, consumers only buy one product and thus the product must be functioning for its intended usage and specification. This means a product or service supplier to end consumer only get one chance to show their product is of good quality. Therefore, all products sold to the consumer market should achieve zero-defect or a very low defect rate such as six sigma quality which is equal to 3.4 defects in one million parts.

Product with zero defects is a dream of every organization. The next big question would be what it takes to achieve zero defects. In the modern world, the end product which reaches the end-user or consumer goes through a very long supply chain, from mother nature raw material such metal, silicon wafer, petrol chemical by-product to form into piece part assemble into sub-assembly and then join together to become final assembly.

All the touchpoint throughout the supply chain will increase error opportunity which could induce defect in a product. Refer to this link on the concept of the supply chain.

The most important condition to strive for the perfection of zero defect is an overall product design with design for manufacturability, serviceability, consumer etc in mind. Quality awareness must start right from the design of the product.

Unfortunately, most of the design only focuses on the functionality of the product which resulted in poor manufacturability, the limited supply chain of material and complicated product which is not user friendly.Many organizations did not realize that zero-defect must be designed in from raw material to piece part to sub-assembly to final assembly. The irony is that those organizations thought manufacturing process can compensate for the poor design and limited material supply base.

Very often a company tend to take short cut design process of a product to save on design cost and time to market which uses substandard material. This had created a ripple effect where company have to live with poor design, spend a huge amount of money to hire resources downstream to manage complicated manufacturing process for the infinite duration of time.

I will share more about design for manufacturability concept which leads to the zero-defect product in the next article. Please do follow this website by clicking on "Follow" on the top right sidebar.

April 11, 2020

Process Input Material - Part purchase from supplier

Material are among the most challenging process input to manage where many companies success are dictated by quality of material they received. The ultimate objective of every company is to ensure supplier are able to delivery consistent good quality materials at the best price. Unfortunately many companies are haunted by poor quality material which had cause them hidden cost which potentially lead lost of business. With this in mind, I had design a systematic approach on how to manage supplier in 7 essential areas. More about this 7 essential areas in supplier quality management can be found in this website :-

http://www.7esupplierquality.com/

We must put equally important emphasis on process input, material that is purchased from a supplier from another manufacturing entity. This material will be transformed through a series of process to become a finished good according to customer requirement. In the modern world, raw material will be transformed into component, sub assembly, final assembly and end item to be delivered to consumer. All transformation will take place in several entity which form a supply chain. Therefore almost all manufacturing entity will be heavily rely on supply parts from external supplier. Incoming parts could dictate a company production and delivery schedule to customer, final part quality and overall manufacturing costs.

Most organizations would assume supplier are able to supply consistent good parts to feed their production line requirement for raw material. In most cases this is a myth and the reality is there are many organizations are being haunted poor incoming part quality which causes late delivery to customer and whole the production schedule are being dictated by incoming material. It is an organization nightmare to live with supplier decommitment of the delivery schedule and poor incoming material quality.

As material is from external plane many companies had either neglected in putting resources to manage purchased part quality or putting resources that had very little knowledge to manage supplier quality. All pain points related supplier incoming material problem can be addressed a systematic approach to manage supplier quality. Supplier quality management (SQM) is a crucial activity for any business that relies on suppliers to provide their goods and services. It involves managing supplier's to deliver product which fulfill customer's needs on time consistently to the agreed quality specification .

August 7, 2018

Correct Mind Set to Problem Solving

One of the most powerful ingredient to achieve consistent good quality would be the organization positive mindset starting from top management. There are many quality/six sigma and lean tools created over the past century to assist in problem solving which enable company to achieve their quality goal. In order to apply lean or six sigma/quality tools successfully to achieve consistent good quality product and bring value to customer, the whole organization must have the positive mindset and require discipline system starting top down.

The role of organization leader is very important in cascading positive mindset to the organization team members top down follow follow the law of gravity. Leadership layer in management of an organization must have clear awareness of problem and potential problem and risk. Only from awareness of the problem, then action plan can be established to address the problem followed by carefully orchestrated execution of the plan to successfully resolve the problem. A problem which get the management attention gets resolve faster than problem which is being hidden in the shop floor.

Dr Deming (1900-1993) 14 points for total quality management required the top leader involvement in implementation. In lean enterprise, top management must not be too far away from the day to day problem. Leader in an organization are suppose to do a regular gemba walk on the production floor or where the activity of transforming input part to final product happen. Gemba walk is not just about walking the shop floor, gemba walk must be designed with objective of eliminating waste which include quality related problem.

A lot organizations had hire the best people which will definitely help to bring an organization quality goal to reality however the best talent cannot function alone. The best people can provide creative solution based on their knowledge and skill set, they will need the team to mobilize the plan solution then only problem get resolve and goal get realize. The biggest authority to mobilize a team to execute a plan would be the top management. Before the mobilization of the plan happen, mobilization of mind had to happen. Only with positive open mindset, then the organization will be open to learning new quality methodology and applied what had been learned. Applying all quality tools will be painful initially as it would mean changes and change is painful to an average human being. Accepting the changes would require a positive mindset. The reward come after change would be great and unfortunately most people are only hoping for the reward without willing to pay the price of change.

July 10, 2018

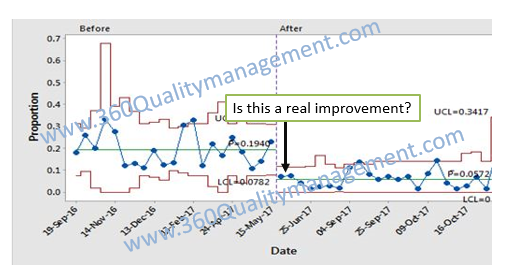

Validate an Improvement in Key Quality Characteristic

Let’s say we put in a lot effort to reduce all the variations in process input, the next question would be how do we know if we have really improve the key quality characteristics.

To begin with, we must be able identify what is the key quality characteristic to the consumer and if the key quality characteristic is measurable. We cannot manage what we cannot measure (Deming, E.W). Do not jump into improving process yet before collecting the current performance of the key characteristic. Once the current performance is known such as yield rate of certain quality attributes or process capability of the quality variables, then improvement effort can kick start. This is follow by data collection again to gather data on quality performance index after improvement.

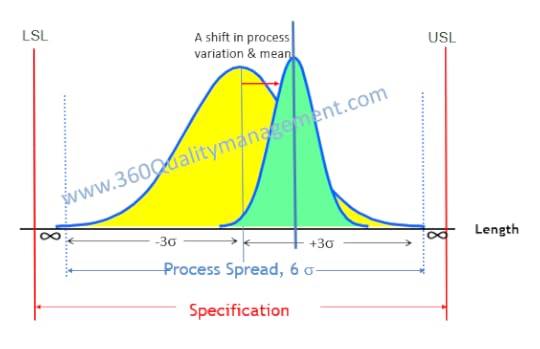

In relation to our above question, we will need to compare before and after improvement plan data to validate if there is real improvement. This mean we will need to check if there is any real shift either in variation or mean of the process.

Shift in process center and variation

Shift in process center and variation

Shift in process center

Shift in process center We have to test our hypothesis that process output quality had improved using statistical hypothesis testing check if null hypothesis, Ho or alternate hypothesis, Ha is valid. Ho usually state that there is no change in status quo or there is NO change in process output quality and Ha state there is a change in process output quality. It is also known as comparative statistics method. In this technique we can compare the following :-

Variable data process center such as mean/median before and after improvementVariable data variation before and after improvement - ANOVAAttribute data mean before and after improvement.

Although statistical computer software had made this technique become simple with a few press of button to get the analyzed results, unfortunately this technique is not widely used or it is not deployed correctly. It could be due to :

Sample size is not sufficient to detect if there is a shift in the processSample does NOT represent actual populationData measurement process is not validated or correctedDo not use the correct testDo not know how to interpret the resultsDo not check whether the data is normally distributedDo not understand the concept of confidence interval which is use to estimate the population attribute in process center and variation.

Statistical comparative methods is a very important technique in decision making such as before making a huge investment to change process. It is the technique to check whether there is a real improvement being made and couple with statistical process control it can also determine if the improvement is sustainable. This is especially critical in high volume mass production environment where it is not possible to measure every single output and yet we have to ensure every single piece in whole population is consistently good quality.