Evelyn Tan's Blog, page 2

December 15, 2020

Supplier Quality Management Course @ Udemy

For those who seek or want to advance their #career in #supplier #quality #management, Would like to share this course on seven essentials on supplier quality management in Udemy . I have put in more than 20 years of knowledge and experience into creating this course. I am an authority in this area where I have wrote books on this subject.

This course will help to prepare for interview which you will outshine your competitor supplier quality manager or engineer post.

You will have life access to this course where you can take your time to finish the course. This is an investment you must make to get ahead in your career as supplier quality management professional.

Click on the image below or scan the QR code to find out more details

#career #interview #supplier #quality #management

Special Promotion : Supplier Quality Management Course @ Udemy only USD11.99

For those who seek or want to advance their #career in #supplier #quality #management, Would like to share this course on seven essentials on supplier quality management in Udemy which currently on launch sale. I have put in more than 20 years of knowledge and experience into creating this course. I am an authority in this area where I have wrote books on this subject.

The launch price USD11.99 vs the original price USD79.99. This course will help to prepare for interview which you will outshine your competitor supplier quality manager or engineer post.

Do grab this chance to get the offer price of USD11.99, you will have life access to this course where you can take your time to finish the course. This is an investment you must make to get ahead.

Click on the image below or scan the QR code to find out more details

#career #interview #supplier #quality #management

December 11, 2020

Which quality cost should be the primary focus of your company? Part 1

A few weeks ago I had run a poll in linkedin group 360 Proactive Quality Engineering to find out which quality cost get the least attention from quality engineering practitioner. (please refer to embedded link on quality cost to learn more on quality cost) 79% had selected prevention cost follow by appraisal and internal cost which reflects the actual situation in the industry.

Most companies had failed to look into #prevention cost due to quality problem is seldom a pain point during the development stage as the biggest challenge to launch a new product would be time to market. The development and marketing team would prefer less interaction with other groups to shorten the design cycle, and less work involves to plan in quality in this silo over the wall approach where I design it and you build it. Sad to say this is still practice in some company till today. Typically, the quality problem will only show up during mass production or worst during customer integration. Every organization who are serious about their profitability should understand the cost of correcting a problem at the customer end is more than thousands times more than rectifying problem during design stage. The table below an example of how quality cost grows in the different product life cycle. Therefore, preventive cost should be the primary focus, especially product with the short product life as product development happens almost every quarter. These types of companies should adopt advance quality planning approach to plan quality into every stage of product life. All quality #engineers should show this table to your management if quality planning is not yet the primary focus of the company. This is also the best proactive approach to adopt.

Product Life

Cost of correcting problem

Design phase

$ 35

Before buying the parts

$177

Before start of mass production

$368

During Mass production

$5900

After shipped to customers

$590000 (many parts could have shipped)

In my next article, I shall share on which cost should be a primary focus where in situation that prevention cost cannot be the primary focus anymore.

December 6, 2020

Channel Evelyn7E premiere – appreciate the support to subscribe

New YouTube channel Evelyn7E premiere today on 7 Dec 2020 especially created for process, quality & management professional. I will share 30 years of my engineering and management experience on hacking into key areas to achieve good results proactively in this channel. There will be video on application quality and management tools and some insights on what to control in specific manufacturing process such as PCBA, mechanical assembly to get stable product. Scan the QR code or click on the video below to go to my channel and subscribe to my channel. Appreciate the sharing with all who can benefit from this channel.

Thank You

November 19, 2020

Proactive leadership in Quality management

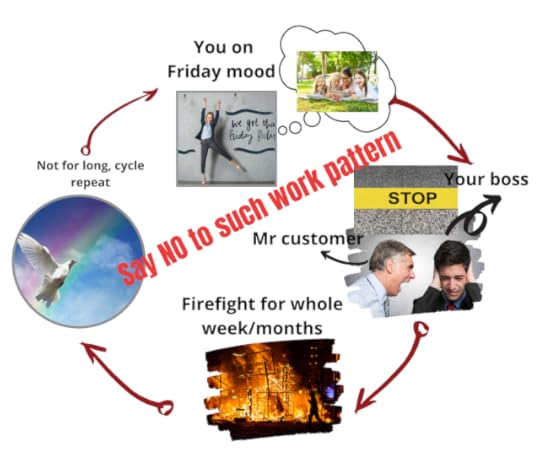

Saying no to such work pattern requires a lot of leadership, planning, courage and communications.

Sometimes we are overwhelmed with so many issues that we are lost and unable to lead ourselves out of those situations. Therefore we continued to firefight for the rest of our working lives and hated our work.

The situation is aggravated if you working for management does not have a clear understanding of what is going on and no objective how to minimize even prevent problems.

We must treat all problems as our enemy, lead ourselves and our team to go to war to conquer this enemy.

Know yourself well, know your enemy even better, a hundred battles fought a hundred battles win.

This is a famous quote by Sun Tzu, a military strategist found in the Art of War, an ancient Chinese military treatise. It starts with taking the lead to understand the problem very well, such as asking questions of what, where, when, who and how and gathering accurate data. This seems to be a simple step; however, many had failed due to lack of knowledge and perspective to look at the problem differently. Once the problem is well defined, we should have some insights if the problem is within our capability to solve or there is no immediate solution. Learn to acknowledge that the problem cannot be prevented with current resources is essential for us to manage the problem.

This is where the problem gets bigger as everyone is only thinking of solving it instead of managing it. I will discuss more about it in the future.

Once you know the problem, then planning is needed to establish a solution to prevent or manage the problem. A problem that is well defined will make planning for action is more straightforward. This will require knowledge gain from learning and experience. Our knowledge is will help us to search for the eureka moment in planning for a solution. We must have the courage to plan for a solution which could go beyond the four walls of the manufacturing facility.

Improvement in minimizing or prevent problem will not happen by just planning. We need to put the problem and action plan into the right perspective so that we can communicate clearly to the management and team member.

Communication to the management is very important to influence the management to support and invest in resources to make the plan into reality.

We must eliminate the victim’s mentality and be proactive in leading ourselves towards a better work-life as the first step towards in being control. If you are in a leadership position, ensure that you are part of the solution to the problem.

November 10, 2020

2020 World Quality Day - Creating Customer Value

World quality day which falls on the second Thursday of Nov was created by the Chartered Quality Institute (CQI) since 1990. This special day was established to bring the awareness and recognition of the quality professionals contribution in delivering quality products to the world. Quality professionals are committed not only in customer quality but also safety in most of the organizations. Many companies around the world will celebrate this momentous occasion in Nov every year. This year theme is creating value to the customer.

Customers are getting more sophisticated over time with upgraded needs & wants, and their voice can be heard over social media. A delighter attribute today might be a must-have in the future according to Kano analysis model on product feature. Every organization should involve quality engineering professional right from the start of product design to ensure quality is plan into the product through the rigour of using the correct quality tools such as kano analysis, quality function deployment and advance product quality plan. A capable quality professional must ensure that the quality voice is heard throughout the organization and drive all functions put in effort in achieving quality at a minimal cost. In my previous LinkedIn article, I have mentioned that quality problem is always hidden and it takes a lot of resources to rectify a problem at customer end.

The customer wants, and needs can evolve, however, one thing that never changes is the customer always require a product which works well to solve their pain point at the lowest cost possible.

Creating value to the customer also this is one of the foundations in lean. This is translated into producing consistently good quality, a defect-free product with minimal quality cost and waste.

May Quality professionals be inspired to create customer value by ensuring quality and safety design into the product and achieve a balance in the voice of the business, the voice of the process and voice of the customer.

Note: CQI and IRCA had prepare an excellent resources to celebrate world quality day @ https://www.quality.org/wqd20-toolkit

November 8, 2020

Which quality cost should be the primary focus of your company? Part 1

A few weeks ago I had run a poll in linkedin group 360 Proactive Quality Engineering to find out which quality cost get the least attention from quality engineering practitioner. (please refer to embedded link on quality cost to learn more on quality cost) 79% had selected prevention cost follow by appraisal and internal cost which reflects the actual situation in the industry.

Most companies had failed to look into #prevention cost due to quality problem is seldom a pain point during the development stage as the biggest challenge to launch a new product would be time to market. The development and marketing team would prefer less interaction with other groups to shorten the design cycle, and less work involves to plan in quality in this silo over the wall approach where I design it and you build it. Sad to say this is still practice in some company till today. Typically, the quality problem will only show up during mass production or worst during customer integration. Every organization who are serious about their profitability should understand the cost of correcting a problem at the customer end is more than thousands times more than rectifying problem during design stage. The table below an example of how quality cost grows in the different product life cycle. Therefore, preventive cost should be the primary focus, especially product with the short product life as product development happens almost every quarter. These types of companies should adopt advance quality planning approach to plan quality into every stage of product life. All quality #engineers should show this table to your management if quality planning is not yet the primary focus of the company. This is also the best proactive approach to adopt.

Product Life

Cost of correcting problem

Design phase

$ 35

Before buying the parts

$177

Before start of mass production

$368

During Mass production

$5900

After shipped to customers

$590000 (many parts could have shipped)

In my next article, I shall share on which cost should be a primary focus where in situation that prevention cost cannot be the primary focus anymore.

October 31, 2020

Overview 360 Proactive Quality Engineering

Solving a quality problem is very expensive as the production line could already produce an infinite quantity of parts which could have reach the customer. This quality issues had caused high manufacturing cost and unhappy customer hence, threaten the profitability of an organization.

It is the dream of every manufacturing organization to achieve a zero-defect product; however, there is not much awareness of what it takes to achieve a defect-free product. Most of the potential problems are hidden in the process input of man, machine, method, material, measure and environment. .

Each process input must be set up and control properly to achieve the desired process output either as a finished good or a process input to a subsequent process. Remember garbage in garbage out. An end consumer product could go through hundreds if not thousands of transformation process per figure below from one manufacturing entity to another per the figure above. A product which had gone through 100 transformation processes with seven process input would have 700 opportunities for error which impact the product quality. Thus, there are many quality engineering books available in the market emphasis heavily on the reactive approach of using problem-solving methods such as six sigma, 8 D corrective action. Most of these reactive methods do not yield sustainable results as there could be an overwhelming problem to firefight.

I have use a systematic proactive approach to manage manufacturing line to attain a consistently good quality product which I will share in 360 Quality Engineering Towards Zero Defect Product in Manufacturing Process, book. For more details please view the video in this article.

Get this book today @ Amazon by scanning the QR code below :

September 17, 2020

The hidden rainbow in 7 manufacturing process inputs - how to find it

There are many factors which could impact each process input and result in variation even if the product is well designed. The table below shows the potential problem in each process input. This is only a fraction of the problem, and there could be more.

Process input

Potential source of variation

Man

Emotion, absent from work, fatigue, no proper training process

Machine

Wear and tear, natural shift or drift of machine

Method

No written work instruction, unclear work instruction, complicated work instruction

Material

Material from multiple suppliers, not able to control supplier process input

Measure

Measure process not set up properly, operator not train to measurement, natural shift of measuring equipment

Environment

Product sensitive to changes in temperature and not proper control in place

If one of the areas is not appropriately planned during the setup, it could results in dire consequences in the final product and end as a reject at the customer site. A proactive approach would be to set up and control each process input properly to minimize the risk of the quality issue in the end product. This had to be coupled with correct process output monitoring which enables early warning if there is potential in the process input. With that say I have prepared a blue print on process input which will guide you on what are the areas to control in each process inputs and would like to share with my audience on this website. It will help you to uncover the hidden rainbow which leads to your pot of gold. Please click on the image below to claim your free gift

September 10, 2020

The hidden rainbow in 7 manufacturing process inputs

The manufacturing process is a series of work which transform materials in a repetitive large-scale environment to a finished product that customer is willing to pay for. All man-made product we use every day from the simplest product such as a toothbrush to a sophisticated high technology product will go through many manufacturing processes in multiple factories. Multiple manufacturing entities, together with transportation and logistic form a long supply chain.

A process must consist of a series of actions that transform process input into the process output per figure below:-

Figure 1. Process input vs process output

The process output can be, in turn, become a process input in the subsequent process. Typical manufacturing process inputs are materials, man, methods, machine, measure and environment known as 5Ms and 1E. Product design is one more process input which will impact the process output. The process output can be, in turn, become a process input in the subsequent process.

Each process input must be set up and control properly to achieve the desired process output either as a finished good or a process input to a subsequent process. Remember garbage in garbage out. An end consumer product could go through hundreds if not thousands of transformation process per figure below from one manufacturing entity to another per the figure above. A product which had gone through 100 transformation processes with seven process input would have 700 opportunities for error which impact the product quality. There could be a potential of scrap or rework cost, which of quality cost if the process input is not setup correctly.

Even a simple toothbrush will consist of multi-tier supplier’s product transformation.

Therefore setting up process input properly is critical to all production process. The next question is, what does it take to set up the manufacturing process inputs correctly to get to the end of the rainbow