Vivek Sood's Blog, page 39

August 10, 2017

Tax Carbon: a societal challenge?

Nowadays, with this new tax, a challenge begins and a new state of mind has been born for consumers and firms. This black tax concerns firstly Supply Chain to reduce the carbon footprint and emissions of dioxide, but it will be spread of every sector of the firms such as Marketing, Production and so on… Mr. Vivek Sood, an analyst in Supply Chain, co-wrote Green Supply Chain – an Action Manifesto – and said about Green Marketing “The purpose of Green Marketing is to broadly communicate this objective and provide the chosen means to achieve this objective. Green Marketing communicates and monitors how organizations are striving to change their internal and external processes, supply chains, infrastructure, systems, and technologies in order to achieve the above objective. Not only is it an integral part of the Green Supply Chains, but it is also an important contributor to ensure that organizations thrive in future.” Of course, getting good results and having green production is no bed of roses, but with some investments and motivations of the whole Supply Chain, there is no reason that it should not work. Firms often believe that having a Green Supply Chain is more expensive than a traditional one although it is often the contrary which happens. Actually, a well-adapted Green Supply Chain enables firms to have higher profits. In a communiqué, Mr. Vivek Sood, the Managing Director of Global Supply Chain Group based in Sydney, explained “Carbon tax can be a real opportunity to change people’s mind, corporate values and organizations. A new era begins which will allow changing the values within the company “

About Global Supply Chain Group:

Global Supply Chain Group is pro-active in creating, configuring, and formulating effective, secure and sustainable supply chains around the world. With a collective supply chain experience of more than 120 years, the senior team in Global Supply Chain Group has worked on more than 100 blue chip projects on all continents adding in excess of $1.5 Billion in value to their clients’ businesses. Large corporations rely on Global Supply Chain Group to deliver outstanding results in their supply chain strategy, supply chain sustainability, supply chain security and supply chain performance. Global Supply Chain Group works very closely, and sometimes anonymously, with the senior executive teams of large corporations to help them win outstanding Global Supply Chain Advantage through:

Supply Chain Transformations and Design,

Supply Chain Strategies and Execution,

Supply Chain Infrastructure and Efficiency,

Supply Chain Information technology and Integration

Supply Chain Processes and Personnel

No matter what your supply chain issues or questions are, it is worth while reaching out and making a connection with us on www.GlobalSupplyChainGroup.com

Contact Details:

Global Supply Chain Group 102/621 Pacific Hwy St Leonards NSW 2065 Australia Telephone +61 2 8920 0694 Fax +61 2 8920 0689 Email: info@globalscgroup.com Web: www.GlobalSCGroup.com

July 17, 2017

Demystifying Supply Chains

I have been asked this question a lot on Quora, as well in my board and other speeches. A lot of supply chain commentary is becoming too technical and mysterious. Supply Chain Software sellers have a vested interest in creating the mystique – similar to what McKinsey used to do about 20 years ago. But Supply Chain Management (SCM) need not be mysterious. Remember, if someone cannot explain it easily enough – they do not understand it well enough.

The purpose of one of my books – Unchain Your Corporation – was precisely this – to demystify the supply chains. This books is written for layperson, can be read in 2–3 hours, and had more than 200 stories and anecdotes to help the readers use complex concepts.

_______________________________________________________________________________________________

Supply Chain Software sellers have a vested interest in creating the mystique – similar to what McKinsey used to do about 20 years ago. But Supply Chain Management (SCM) need not be mysterious. Remember, if someone cannot explain it easily enough – they do not understand it well enough.___________________________________________________________________________________________________________________________

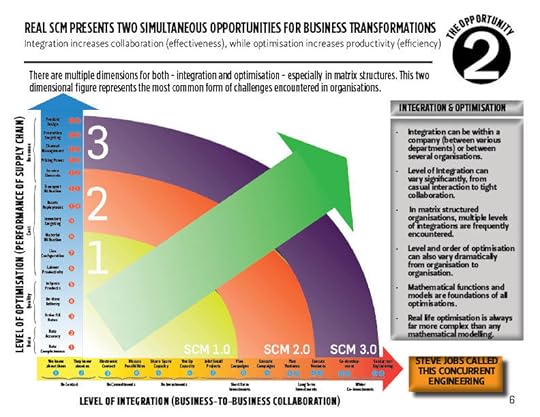

At its core, SCM is just about two things – integration, and optimisation.

Integration of various functions (purchasing, production, logistics, inventory management, finance, sales) within a company. And, Integration of of various companies that form a supply chain together to serve an end consumer.

Optimisation – is the art of getting the best results from the same inputs. You will be surprised to know that most GPS software do not even give you the optimum route even if they have real-time traffic information. The key to testing optimisation is by doing the same exercise manually and comparing against the results of the software. There are clearly degrees of Integration and Optimisation. Higher levels of Integration and/or Optimisation will lead to higher level of efficacy in supply chains.

See the figure below – that comes from one of my board speeches:

[image error]

If you supply chain consultants are not telling you these two simple truths, then all the talk of automation, big data software and driverless vehicles is a pipedream without a purpose.

And, if your Supply Chain MBA is not teaching you these two basics then you might have wasted 2 years and thousands of dollars.

Here is why… …Everything else in supply chain stands on those two foundations. Your supply chain relationships are part of integration effort, and automation is part of optimisation effort.

The Single Biggest Mistake in Business Transformations

If I have seen it once, I have seen it a hundred times. A new person is brought in with a clear mandate. The things are meant to change. Out with the old, and in with the new. The new person comes in with a great fanfare, and takes over. Then he/she starts taking stock of the situation. And takes more stock of the situation. Gets the consultants. Does a study. And, more studies. And more stock of the situation.

Meanwhile, the chairman is stewing in his chair. The board is exasperated. They see a lot fancy reports from the consultants. But they are waiting for action. Which comes in small dribs and drabs. Seems like one step forward and three steps backward. They start saying things like – ‘even the wrong action is better than no action.’

And, that is when you know that the single biggest mistake in business transformation is being repeated again.

Here is a typical scenario:

It had been two months after the internal announcement about achieving a milestone, and no one had seen the spark of business transformation yet. The momentum has been lost. When employees clapped their hands a couple of months ago on hearing the speech about successfully increasing efficiency by 10%, an impressive quick win, management should have taken the opportunity to introduce the next initiative.

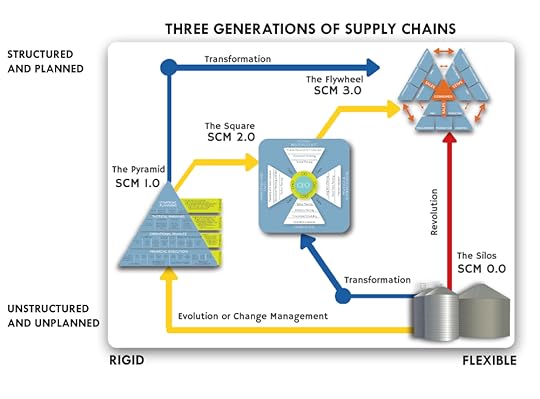

Unfortunately, cases like this are not rare. Driven at the wrong speed without an appropriate line-up of actions will extinguish the initial enthusiasm, causing boredom and even withdrawal. As we have seen in my book UNCHAIN YOUR CORPORATION, the journey from supply chain 0.0 to 1.0, to 2.0, to 3.0 is very interesting, and challenging. Here is the relevant framework from the book:

[image error]

Obviously, if your company enjoys healthy margins and is in relaxed circumstances, you can move just one step at a time – from SCM 0.0 to 1.0 or from SCM 1.0 to 2.0 or from SCM 2.0 to 3.0. All you might need is a slow evolution over number of years, where your company comes to the realize the need to change over 2-3 years, and then gradually carries out that change over another 2-3 years.

During this process, if the market conditions change and, margins experience a squeeze, your company can always hasten the cycle by deploying professional change managers, where a six-year planning and execution cycle can be easily halved to 2-3 years.

However, companies can also jump one step in the process, from SCM 0.0 to 2.0, or from SCM 1.0 to 3.0 by deliberate supply chain transformation, which helps them achieve faster results, with less risk of always chasing the trend. In this particular case, the danger is real that the process can be carried out too slow or too fast, depending on how the transformation is created.

To give you an example of a transformation which was carried out too fast, let’s consider the case of British Petroleum and its oil rig in the Gulf of Mexico. The full case study is our book Outsourcing 3.0 but here we will repeat just the most pertinent facts. Obviously, their supply chain 3.0 was configured with a number of suppliers of BP, including the owner of the rig, the operator of the rig, the supplier of the underwater equipment used on the rig, which failed, and the user of that underwater equipment. Unfortunately, the transformation had been carried out so rapidly that the risks were not being managed prudently enough. As a result, a small failure in the supply chain resulted in massive losses, amounting to tens of billions of dollars and a blame-game at the end of it all.

On the other hand, examples also abound where companies drag out the transformation too long, at the pace of slow evolution or change management. We have seen numerous companies go bankrupt, rather than hasten the transformation process.

[image error]

In fact, take a look at any company declaring bankruptcy, whether in automotive, aviation or any other sector, and you will see apparent signs of failed transformations due to a slow pace, or a lack of understanding of the various stages along the way.

On the other hand, if you want to see examples of companies that have carried out the transformation just right, try and examine those whose share prices have gone up significantly in comparison to the market benchmarks, and then discern whether this result is due to a stroke of luck – for example, a fertilizer company getting lucky thanks to the right amount of rain 3 years in a row – or whether it is the result of a professional business transformation, carried out from one stage to next in a systematic manner.

[image error][/vc_column_text][/vc_column][/vc_row]

What Business Executives Can Learn From The Story of Brazil’s Soccer Transformation

In the early 90s, more than two decades since its last World Cup championship title, Brazil hungered for the trophy more than any other country on earth. Yet the scars from its 1950 campaign were still not totally erased. Dubbed as the saddest day in Brazilian soccer history, July 16 1950 was the day Brazil lost the championship to Uruguay right on their home soil, and the winner’s speech prepared for Brazil had to be scrapped. At this point, you may be wondering what the Brazilian soccer story has to do with business. Surprisingly, the analogy can ring more bells than you think.

In the early 90s, more than two decades since its last World Cup championship title, Brazil hungered for the trophy more than any other country on earth. Yet the scars from its 1950 campaign were still not totally erased. Dubbed as the saddest day in Brazilian soccer history, July 16 1950 was the day Brazil lost the championship to Uruguay right on their home soil, and the winner’s speech prepared for Brazil had to be scrapped. At this point, you may be wondering what the Brazilian soccer story has to do with business. Surprisingly, the analogy can ring more bells than you think.

Brazilian soccer dilemma

Back to the 1990s, during the run-up to World Cup of 1994, coach Carlos Alberto Parreira was determined not to let history happen again. But, he only knew too well the magnitude of challenge faced by Brazilian National soccer team. On one hand, the cheering of endeared crowds as soccer legend Pelé and his teammates lifted the World Cup trophy in 1970 still reverberated in his head. On the other hand, the grief-stricken silence of nationwide fans as they watched Uruguay took away their dream in 1950 was hauntingly real. Somewhere in between the past and present, coach Parreira pondered upon the Brazilian samba-inspired way of playing soccer. In a country where every schoolboy dreamed of being Pelé, arguably the best soccer player in Brazil’s history and the most well-known on earth, it was hard to tell people to play differently. Brazilian children were always taught to play soccer with flair. They were enamored with the wizardry of foot play and dribbling, of playing soccer with very nimble dexterous patches of feet. But the famous method of Pelé was not working anymore. The dry spell of World Cup titles despite fiery displays of skills between 1971 up till the early 90s stood as a daunting reminder. What previous coaches did not realize was soccer had changed a lot on the global landscape since Brazil’s last creative zenith in 1970. As the sport became increasingly popular in Europe, people there started to practice their own soccer philosophy which seemed to counteract Brazil’s individualistic and improvisational style. Germany, Italy and the Netherlands began to make their names more prominent in the World Cup finals. Soccer was played on Astroturf by powerful players and teams who played like network of players passing the ball rapidly to each other rather than keeping it to themselves. In other words, the network structural, defensive and strength-based style of European soccer had trounced the individual Brazilian wizardry.

determined not to let history happen again. But, he only knew too well the magnitude of challenge faced by Brazilian National soccer team. On one hand, the cheering of endeared crowds as soccer legend Pelé and his teammates lifted the World Cup trophy in 1970 still reverberated in his head. On the other hand, the grief-stricken silence of nationwide fans as they watched Uruguay took away their dream in 1950 was hauntingly real. Somewhere in between the past and present, coach Parreira pondered upon the Brazilian samba-inspired way of playing soccer. In a country where every schoolboy dreamed of being Pelé, arguably the best soccer player in Brazil’s history and the most well-known on earth, it was hard to tell people to play differently. Brazilian children were always taught to play soccer with flair. They were enamored with the wizardry of foot play and dribbling, of playing soccer with very nimble dexterous patches of feet. But the famous method of Pelé was not working anymore. The dry spell of World Cup titles despite fiery displays of skills between 1971 up till the early 90s stood as a daunting reminder. What previous coaches did not realize was soccer had changed a lot on the global landscape since Brazil’s last creative zenith in 1970. As the sport became increasingly popular in Europe, people there started to practice their own soccer philosophy which seemed to counteract Brazil’s individualistic and improvisational style. Germany, Italy and the Netherlands began to make their names more prominent in the World Cup finals. Soccer was played on Astroturf by powerful players and teams who played like network of players passing the ball rapidly to each other rather than keeping it to themselves. In other words, the network structural, defensive and strength-based style of European soccer had trounced the individual Brazilian wizardry.

The champion’s comeback

Coach Parreira knew the painful time had come for a total transformation. It was not as though Brazil had never had that spark of Europe’s tactical organization before. In fact, in the very last year of Pelé’s appearance in a World Cup, Brazil did adopt a compactness-based style where the team attacked in blocks with some cohesiveness between different sectors. The job of coach Parreira then was to ignite the will to change, even if it meant starting from the root.  While it was not possible to change the entire soccer mentality from 5-year-old children in time for the upcoming World Cup, he determined that he would have to change the selection practices. In fact, his idea was so humongous that it was almost equal to creating a holistic large-scale business transformation that most CEOs have to do at least once every three to five years in their businesses today. Fortunately, in 1994, Brazil made it, they won their fourth World Cup champion title. Despite being rather flat and lacking in flamboyant, spectacular footwork, the functional Brazilian unit defeated Italy and marked its successful re-assertion as a formidable team. Under coach Parreira’s guidance the team was able to learn the new model of the game, putting behind the time when it seemed the entire future of South American soccer was in doldrums.

While it was not possible to change the entire soccer mentality from 5-year-old children in time for the upcoming World Cup, he determined that he would have to change the selection practices. In fact, his idea was so humongous that it was almost equal to creating a holistic large-scale business transformation that most CEOs have to do at least once every three to five years in their businesses today. Fortunately, in 1994, Brazil made it, they won their fourth World Cup champion title. Despite being rather flat and lacking in flamboyant, spectacular footwork, the functional Brazilian unit defeated Italy and marked its successful re-assertion as a formidable team. Under coach Parreira’s guidance the team was able to learn the new model of the game, putting behind the time when it seemed the entire future of South American soccer was in doldrums.  There is a lot to learn from this transformation feat of Brazilian and South American soccer. Their teams have moved from an individual-based game to a network of players moving together in formations, conquering the opponents by outwitting them, by outsmarting them, and by outnetworking them by using a better method. In the next blog in this series I will talk about another national team – in another sport – which never made the transformation. I am closely connected to that team and there is much to learn from them too – though it is not as happy story. If you would like to read the full article in PDF format, please click here.

There is a lot to learn from this transformation feat of Brazilian and South American soccer. Their teams have moved from an individual-based game to a network of players moving together in formations, conquering the opponents by outwitting them, by outsmarting them, and by outnetworking them by using a better method. In the next blog in this series I will talk about another national team – in another sport – which never made the transformation. I am closely connected to that team and there is much to learn from them too – though it is not as happy story. If you would like to read the full article in PDF format, please click here.

In Supply Chains Opportunity Only Knocks Once

Free chapters of the book THE 5-STAR BUSINESS NETWORKS for senior executives and CXOs reveal secrets of how to leverage technologies and techniques of supply chain winners to create formidable lead and impermeable advantage over competitors. These chapters are only available for limited time by sending an email to info@globalscgroup.com For more information on the book, go to www.5starbusinessnetwork.com

Free chapters of the book THE 5-STAR BUSINESS NETWORKS for senior executives and CXOs reveal secrets of how to leverage technologies and techniques of supply chain winners to create formidable lead and impermeable advantage over competitors. These chapters are only available for limited time by sending an email to info@globalscgroup.com For more information on the book, go to www.5starbusinessnetwork.com

High Demand for Real Supply Chain Experts

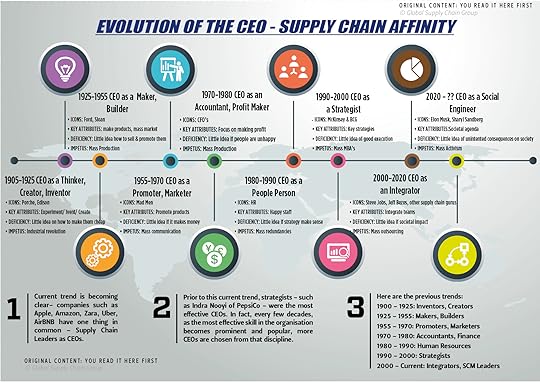

Good solid supply chain thinkers are in high demand and low supply. I would know, I run this company called Global Supply Chain Group for the last 17 years. It appears that it was not too long ago (when we formed this company) – most business people were struggling to understand what is supply chain and what does it do. We have come a long way since then. Every politicians speech today is laced with references to global supply chains and business networks that run the commerce on earth today. Companies that are seen as supply chain trend setters are leaving everyone else (even in adjoining industries) biting the dust. Take a look at the chart below:

Good solid supply chain thinkers are in high demand and low supply. I would know, I run this company called Global Supply Chain Group for the last 17 years. It appears that it was not too long ago (when we formed this company) – most business people were struggling to understand what is supply chain and what does it do. We have come a long way since then. Every politicians speech today is laced with references to global supply chains and business networks that run the commerce on earth today. Companies that are seen as supply chain trend setters are leaving everyone else (even in adjoining industries) biting the dust. Take a look at the chart below:

But Amazon.com is not the only one. Current trend is becoming clear- companies such as Apple, Zara, Uber, AirBNB have one thing in common – Supply Chain Leaders as CEOs. Integrators are in high demand. Optimisers rule the roost. Every era has its own heralds and the mantle changes every few decades. As as example, it only one or two decades ago that strategists coming from McKinsey or 3Bs (BCG, Bain, Booz) were the prime candidates for the role of the CEOs. What made this necessary was the need for strategic thinking that was missing at the highest level before that. But clearly the mantle has passed on the the integrators / real supply chain leaders now. Here are the previous trends:

1900 – 1925: Inventors, Creators

1925 – 1955: Makers, Builders

1955 – 1970: Promoters, Marketers

1970 – 1980: Accountants, Finance

1980 – 1990: Human Resources

1990 – 2000: Strategists

2000 – Current: Integrators, SCM Leaders

I know, you are asking where is the proof. Take a look at the picture below:

It will take a long time to explain the picture above, if you don’t get it by seeing it. It is also perhaps unnecessary in that case. Suffice it to say that two skills are becoming critical for business leadership:

Integration – of various parts of the 5-STAR Business network, internal and external resources, into a complete unit that delivers the customer experience

Optimisation – that enables sound profitability while delivering the customer experience

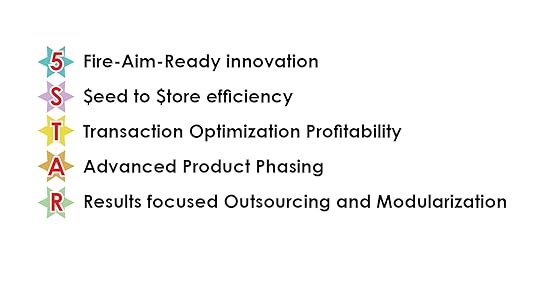

I have many other pretty pictures to expound these points, but I would rather focus on the outcomes. So, what would you expect if above two skills were available in abundance? For sure, you would expect good business outcomes. These could take the form of any of the 5 possible themes:

This is the topic I cover in great deal of detail in my book THE 5-STAR BUSINESS NETWORK – so I will not talk about it in this post. Rather I want to focus on the reason I wrote this blog:

Now, if you have read it this far, there is a good chance that you know someone who will benefit from this information. Earn yourself some brownie points by letting them know – by sharing directly, or via groups. It only take 15 seconds.

[et_pb_section admin_label=”section”][et_pb_row admin_lab...

DEMYSTIFYING SUPPLY CHAIN MANAGEMENT

I have been asked this question a lot on Quora, as well in my board and other speeches. A lot of supply chain commentary is becoming too technical and mysterious. Supply Chain Software sellers have a vested interest in creating the mystique – similar to what McKinsey used to do about 20 years ago. But Supply Chain Management (SCM) need not be mysterious. Remember, if someone cannot explain it easily enough – they do not understand it well enough. The purpose of one of my books – Unchain Your Corporation – was precisely this – to demystify the supply chains. This books is written for layperson, can be read in 2–3 hours, and had more than 200 stories and anecdotes to help the readers use complex concepts. At its core, SCM is just about two things – integration, and optimisation. Integration of various functions (purchasing, production, logistics, inventory management, finance, sales) within a company. And, Integration of of various companies that form a supply chain together to serve an end consumer. Optimisation – is the art of getting the best results from the same inputs. You will be surprised to know that most GPS software do not even give you the optimum route even if they have real-time traffic information. The key to testing optimisation is by doing the same exercise manually and comparing against the results of the software. There are clearly degrees of Integration and Optimisation. Higher levels of Integration and/or Optimisation will lead to higher level of efficacy in supply chains. See the figure below – that comes from one of my board speeches:

I have been asked this question a lot on Quora, as well in my board and other speeches. A lot of supply chain commentary is becoming too technical and mysterious. Supply Chain Software sellers have a vested interest in creating the mystique – similar to what McKinsey used to do about 20 years ago. But Supply Chain Management (SCM) need not be mysterious. Remember, if someone cannot explain it easily enough – they do not understand it well enough. The purpose of one of my books – Unchain Your Corporation – was precisely this – to demystify the supply chains. This books is written for layperson, can be read in 2–3 hours, and had more than 200 stories and anecdotes to help the readers use complex concepts. At its core, SCM is just about two things – integration, and optimisation. Integration of various functions (purchasing, production, logistics, inventory management, finance, sales) within a company. And, Integration of of various companies that form a supply chain together to serve an end consumer. Optimisation – is the art of getting the best results from the same inputs. You will be surprised to know that most GPS software do not even give you the optimum route even if they have real-time traffic information. The key to testing optimisation is by doing the same exercise manually and comparing against the results of the software. There are clearly degrees of Integration and Optimisation. Higher levels of Integration and/or Optimisation will lead to higher level of efficacy in supply chains. See the figure below – that comes from one of my board speeches:

If you supply chain consultants are not telling you these two simple truths, then all the talk of automation, big data software and driverless vehicles is a pipedream without a purpose. And, if your Supply Chain MBA is not teaching you these two basics then you might have wasted 2 years and thousands of dollars. Here is why… …Everything else in supply chain stands on those two foundations. Your supply chain relationships are part of integration effort, and automation is part of optimisation effort.

THE SINGLE BIGGEST MISTAKE IN BUSINESS TRANSFORMATIONS

If I have seen it once, I have seen it a hundred times. A new person is brought in with a clear mandate. The things are meant to change. Out with the old, and in with the new. The new person comes in with a great fanfare, and takes over. Then he/she starts taking stock of the situation. And takes more stock of the situation. Gets the consultants. Does a study. And, more studies. And more stock of the situation. Meanwhile, the chairman is stewing in his chair. The board is exasperated. They see a lot fancy reports from the consultants. But they are waiting for action. Which comes in small dribs and drabs. Seems like one step forward and three steps backward. They start saying things like – ‘even the wrong action is better than no action.’ And, that is when you know that the single biggest mistake in business transformation is being repeated again. Here is a typical scenario: It had been two months after the internal announcement about achieving a milestone, and no one had seen the spark of business transformation yet. The momentum has been lost. When employees clapped their hands a couple of months ago on hearing the speech about successfully increasing efficiency by 10%, an impressive quick win, management should have taken the opportunity to introduce the next initiative. Unfortunately, cases like this are not rare. Driven at the wrong speed without an appropriate line-up of actions will extinguish the initial enthusiasm, causing boredom and even withdrawal. As we have seen in my book UNCHAIN YOUR CORPORATION, the journey from supply chain 0.0 to 1.0, to 2.0, to 3.0 is very interesting, and challenging. Here is the relevant framework from the book:

If I have seen it once, I have seen it a hundred times. A new person is brought in with a clear mandate. The things are meant to change. Out with the old, and in with the new. The new person comes in with a great fanfare, and takes over. Then he/she starts taking stock of the situation. And takes more stock of the situation. Gets the consultants. Does a study. And, more studies. And more stock of the situation. Meanwhile, the chairman is stewing in his chair. The board is exasperated. They see a lot fancy reports from the consultants. But they are waiting for action. Which comes in small dribs and drabs. Seems like one step forward and three steps backward. They start saying things like – ‘even the wrong action is better than no action.’ And, that is when you know that the single biggest mistake in business transformation is being repeated again. Here is a typical scenario: It had been two months after the internal announcement about achieving a milestone, and no one had seen the spark of business transformation yet. The momentum has been lost. When employees clapped their hands a couple of months ago on hearing the speech about successfully increasing efficiency by 10%, an impressive quick win, management should have taken the opportunity to introduce the next initiative. Unfortunately, cases like this are not rare. Driven at the wrong speed without an appropriate line-up of actions will extinguish the initial enthusiasm, causing boredom and even withdrawal. As we have seen in my book UNCHAIN YOUR CORPORATION, the journey from supply chain 0.0 to 1.0, to 2.0, to 3.0 is very interesting, and challenging. Here is the relevant framework from the book:  Obviously, if your company enjoys healthy margins and is in relaxed circumstances, you can move just one step at a time – from SCM 0.0 to 1.0 or from SCM 1.0 to 2.0 or from SCM 2.0 to 3.0. All you might need is a slow evolution over number of years, where your company comes to the realize the need to change over 2-3 years, and then gradually carries out that change over another 2-3 years. During this process, if the market conditions change and, margins experience a squeeze, your company can always hasten the cycle by deploying professional change managers, where a six-year planning and execution cycle can be easily halved to 2-3 years. However, companies can also jump one step in the process, from SCM 0.0 to 2.0, or from SCM 1.0 to 3.0 by deliberate supply chain transformation, which helps them achieve faster results, with less risk of always chasing the trend. In this particular case, the danger is real that the process can be carried out too slow or too fast, depending on how the transformation is created. To give you an example of a transformation which was carried out too fast, let’s consider the case of British Petroleum and its oil rig in the Gulf of Mexico. The full case study is our book Outsourcing 3.0 but here we will repeat just the most pertinent facts. Obviously, their supply chain 3.0 was configured with a number of suppliers of BP, including the owner of the rig, the operator of the rig, the supplier of the underwater equipment used on the rig, which failed, and the user of that underwater equipment. Unfortunately, the transformation had been carried out so rapidly that the risks were not being managed prudently enough. As a result, a small failure in the supply chain resulted in massive losses, amounting to tens of billions of dollars and a blame-game at the end of it all. On the other hand, examples also abound where companies drag out the transformation too long, at the pace of slow evolution or change management. We have seen numerous companies go bankrupt, rather than hasten the transformation process.

Obviously, if your company enjoys healthy margins and is in relaxed circumstances, you can move just one step at a time – from SCM 0.0 to 1.0 or from SCM 1.0 to 2.0 or from SCM 2.0 to 3.0. All you might need is a slow evolution over number of years, where your company comes to the realize the need to change over 2-3 years, and then gradually carries out that change over another 2-3 years. During this process, if the market conditions change and, margins experience a squeeze, your company can always hasten the cycle by deploying professional change managers, where a six-year planning and execution cycle can be easily halved to 2-3 years. However, companies can also jump one step in the process, from SCM 0.0 to 2.0, or from SCM 1.0 to 3.0 by deliberate supply chain transformation, which helps them achieve faster results, with less risk of always chasing the trend. In this particular case, the danger is real that the process can be carried out too slow or too fast, depending on how the transformation is created. To give you an example of a transformation which was carried out too fast, let’s consider the case of British Petroleum and its oil rig in the Gulf of Mexico. The full case study is our book Outsourcing 3.0 but here we will repeat just the most pertinent facts. Obviously, their supply chain 3.0 was configured with a number of suppliers of BP, including the owner of the rig, the operator of the rig, the supplier of the underwater equipment used on the rig, which failed, and the user of that underwater equipment. Unfortunately, the transformation had been carried out so rapidly that the risks were not being managed prudently enough. As a result, a small failure in the supply chain resulted in massive losses, amounting to tens of billions of dollars and a blame-game at the end of it all. On the other hand, examples also abound where companies drag out the transformation too long, at the pace of slow evolution or change management. We have seen numerous companies go bankrupt, rather than hasten the transformation process.  In fact, take a look at any company declaring bankruptcy, whether in automotive, aviation or any other sector, and you will see apparent signs of failed transformations due to a slow pace, or a lack of understanding of the various stages along the way. On the other hand, if you want to see examples of companies that have carried out the transformation just right, try and examine those whose share prices have gone up significantly in comparison to the market benchmarks, and then discern whether this result is due to a stroke of luck – for example, a fertilizer company getting lucky thanks to the right amount of rain 3 years in a row – or whether it is the result of a professional business transformation, carried out from one stage to next in a systematic manner.

In fact, take a look at any company declaring bankruptcy, whether in automotive, aviation or any other sector, and you will see apparent signs of failed transformations due to a slow pace, or a lack of understanding of the various stages along the way. On the other hand, if you want to see examples of companies that have carried out the transformation just right, try and examine those whose share prices have gone up significantly in comparison to the market benchmarks, and then discern whether this result is due to a stroke of luck – for example, a fertilizer company getting lucky thanks to the right amount of rain 3 years in a row – or whether it is the result of a professional business transformation, carried out from one stage to next in a systematic manner.

The Second Biggest Mistake in Business Transformations

In case you are wondering why I am focusing on the second biggest mistake rather than the biggest one – it is because I have already written a blog post on that topic last week. Here is the link to it. But the second biggest mistake is even more common and well known. It is so easy to recognise that there are a whole lot of cliches used to describe it. Yet it is so common that it worth spending half an hour writing a blog post about it. Even if 10 business transformations are put back on track after reading this blogpost – it would have done its job. After all each derailed business transformation is a huge waste of human effort and ingenuity.. So, what are the cliches that are used to describe this second mistake. I am sure everyone is familiar with these: Putting the Horse Before the Cart. Confusing the Cause with Effect. Post Hoc Fallacy A theoretical discussion of human fallacies is out of scope of this blogpost. You can read more about these here. Practical observation shows that most business transformations require at least some degree of IT upgrade. In many cases these IT upgrades take a life of their own and business objectives of the transformation projects start taking a back seat to these technological considerations. In my book UNCHAIN YOUR CORPORATIONS I have given more than 20 examples of this phenomenon, in various contexts. Below I quote from the book: Modern supply chains collect information at each node of the network. This rich data is

In case you are wondering why I am focusing on the second biggest mistake rather than the biggest one – it is because I have already written a blog post on that topic last week. Here is the link to it. But the second biggest mistake is even more common and well known. It is so easy to recognise that there are a whole lot of cliches used to describe it. Yet it is so common that it worth spending half an hour writing a blog post about it. Even if 10 business transformations are put back on track after reading this blogpost – it would have done its job. After all each derailed business transformation is a huge waste of human effort and ingenuity.. So, what are the cliches that are used to describe this second mistake. I am sure everyone is familiar with these: Putting the Horse Before the Cart. Confusing the Cause with Effect. Post Hoc Fallacy A theoretical discussion of human fallacies is out of scope of this blogpost. You can read more about these here. Practical observation shows that most business transformations require at least some degree of IT upgrade. In many cases these IT upgrades take a life of their own and business objectives of the transformation projects start taking a back seat to these technological considerations. In my book UNCHAIN YOUR CORPORATIONS I have given more than 20 examples of this phenomenon, in various contexts. Below I quote from the book: Modern supply chains collect information at each node of the network. This rich data is  methodically analyzed to optimize demand, supply, inventory, costs and service levels to create the best profit results. Not many people know this art – while there might be many pretenders. The next component in business transformations is the informational part of the business network, which is strongly bounded by its IT systems. A word of caution, though, IT should always be viewed as a means to an end rather than the end in itself. In other words, systems are implemented to facilitate information exchange that is conducive to business transformation. In the project we were working on, the challenge was indeed, moving the system from the regional to the global structure. Apart from having islands of data to consolidate, the company also found themselves dissatisfied with a system that met only 70% of its needs. Even though you may be tempted by flexibility as it offers more room for maneuver in the future, every additional bit of flexibility breeds corresponding complexity. To some extent, if a supply chain forms the backbone of your business, then IT is like the nervous system that helps circulate pulses of information and intelligence around the body. To get a more realistic picture of the complexity, type “supply chain software” into Google and you will get more than 75 million results. How do you know which one is the right one? Though many of them will pretend that they can, there is not a single piece of software that can do everything that you require from a supply chain software solution. Plethora of tools are available – each with its own peculiarities and limitations. Old ERP type systems can lead your operations into a big hole from which it will take years to emerge. Furthermore, each tool is most suitable for certain situations, and unsuitable for other situations. You need the ability get the right tools – just the ones that suit your situation – and combine them well. As mentioned above, even though IT is not a solution to every problem, it should not be allowed to create even more problems than those that exist in the first place. I have dedicated a whole chapter to IT systems in my book The 5-Star Business Network and here I would like to focus only on a few key things. To get this component right, you also need to see things through the eyes of the system provider. It is a delicate dance between rigid functionality and flexible business outcome. How do you choose the right software for, say forecasting, from among more than 2,500 such systems? How do you link this system to the other systems it needs to work closely with – say inventory management software? How do you pick the right inventory management software from among more than 2,000 systems that claim to do more or less the same thing? Do you go for a single solution that is about 50%-60% right, at best – or do you go for a best-of-breed solution that can cover more than 85% of your need, if you do it properly? All these are very complex questions to answer. Figure below, taken from my book The 5-Star Business Network, illustrates just some of the ways a business can falter along their road to using IT for business transformation.

methodically analyzed to optimize demand, supply, inventory, costs and service levels to create the best profit results. Not many people know this art – while there might be many pretenders. The next component in business transformations is the informational part of the business network, which is strongly bounded by its IT systems. A word of caution, though, IT should always be viewed as a means to an end rather than the end in itself. In other words, systems are implemented to facilitate information exchange that is conducive to business transformation. In the project we were working on, the challenge was indeed, moving the system from the regional to the global structure. Apart from having islands of data to consolidate, the company also found themselves dissatisfied with a system that met only 70% of its needs. Even though you may be tempted by flexibility as it offers more room for maneuver in the future, every additional bit of flexibility breeds corresponding complexity. To some extent, if a supply chain forms the backbone of your business, then IT is like the nervous system that helps circulate pulses of information and intelligence around the body. To get a more realistic picture of the complexity, type “supply chain software” into Google and you will get more than 75 million results. How do you know which one is the right one? Though many of them will pretend that they can, there is not a single piece of software that can do everything that you require from a supply chain software solution. Plethora of tools are available – each with its own peculiarities and limitations. Old ERP type systems can lead your operations into a big hole from which it will take years to emerge. Furthermore, each tool is most suitable for certain situations, and unsuitable for other situations. You need the ability get the right tools – just the ones that suit your situation – and combine them well. As mentioned above, even though IT is not a solution to every problem, it should not be allowed to create even more problems than those that exist in the first place. I have dedicated a whole chapter to IT systems in my book The 5-Star Business Network and here I would like to focus only on a few key things. To get this component right, you also need to see things through the eyes of the system provider. It is a delicate dance between rigid functionality and flexible business outcome. How do you choose the right software for, say forecasting, from among more than 2,500 such systems? How do you link this system to the other systems it needs to work closely with – say inventory management software? How do you pick the right inventory management software from among more than 2,000 systems that claim to do more or less the same thing? Do you go for a single solution that is about 50%-60% right, at best – or do you go for a best-of-breed solution that can cover more than 85% of your need, if you do it properly? All these are very complex questions to answer. Figure below, taken from my book The 5-Star Business Network, illustrates just some of the ways a business can falter along their road to using IT for business transformation. FIGURE: PROBLEMS WITH USING IT FOR BUSINESS TRANSFORMATIONS Your job is to mix and match a best-of-breed solution suite, then configure the pieces to form an integrated system, that meets your rapidly changing needs in a business transformation. How? We need to revisit the strategic component, to examine the level of disconnect between the corporate strategy and the IT capabilities and carefully find tools that fill that gap. In the past, it might have been the case that corporate strategies were made up in the air, then supply chain strategies were formed by people down in the warehouses based on their own assumptions about what the business wanted to achieve, and the IT staff work in their own cubicles to provide systems based on poorly articulated needs. If the above example of three isolated types of strategies resonates with your personal experience, you would also concur that despite numerous vocal calls for enterprise-wide collaboration, people still continue to work in silos. This is equal to saying many companies are still staying at Supply Chain 0.0 while others are moving towards 1.0 or 2.0 or, even mastering Supply Chain 3.0.

FIGURE: PROBLEMS WITH USING IT FOR BUSINESS TRANSFORMATIONS Your job is to mix and match a best-of-breed solution suite, then configure the pieces to form an integrated system, that meets your rapidly changing needs in a business transformation. How? We need to revisit the strategic component, to examine the level of disconnect between the corporate strategy and the IT capabilities and carefully find tools that fill that gap. In the past, it might have been the case that corporate strategies were made up in the air, then supply chain strategies were formed by people down in the warehouses based on their own assumptions about what the business wanted to achieve, and the IT staff work in their own cubicles to provide systems based on poorly articulated needs. If the above example of three isolated types of strategies resonates with your personal experience, you would also concur that despite numerous vocal calls for enterprise-wide collaboration, people still continue to work in silos. This is equal to saying many companies are still staying at Supply Chain 0.0 while others are moving towards 1.0 or 2.0 or, even mastering Supply Chain 3.0.  Figure – The process and service component As you can see from Figure above, which shows typical processes in a supply chain 1.0, there are four levels that need to be weaved into a cohesive whole. Typically, there can be missing links between processes – vertically, or even horizontally. That means, someone working at the operational level may not know how their work is related to the work of someone at the tactical level. Even worse, for instance, a delivery scheduler may not know how his work output related to that of his next cubicle neighbor – the customer forecast expert. During a transformation, processes and services may get streamlined, re-aligned or even created from scratch to accommodate change. That is why it is pivotal to keep in mind how they all fit together by devising a visual presentation such as the pyramid diagram above. I was having a conversation with one of the senior executives responsible for business transformation in a large-sized industrial company with operations and plants across the developed world. This particular person had come from one of the top tier global consulting houses and obviously was very well versed in the hypothesis-driven problem-solving approach, which both he and I had learned in our formative years in top tier consulting houses. He was adamant that this approach would be enough to carry out a large-scale supply chain transformation in his business. Hence, he was very skeptical about the supply chain methodologies that we were espousing. In his mind, he could derive the same results from the first principles using his hypothesis-driven approach. And I was patiently explaining to him the difference between going back to the first principles to create a new approach, and deploying a tried and tested approach for supply chain transformations which had the benefit of having adapted the same hypothesis-driven approach. So I gave him an example of the early stage motorcars where people were still using solid rubber tires and a number of fittings which were a carry-over from the days of horse buggies. Of course, if he had the luxury of time and budget to make all the mistakes there were, he could probably recreate a modern-day motorcar, going through all the stages of evolution. He was smarter than most of the population, so he could perhaps complete the task in 20% of the time that it took for the actual evolution to take place and perhaps, at 20% of the budget. Yet, if a modern-day motorcar was already developed, wouldn’t he be better off testing if it suited his purpose and adapting it for his use? The role of “process” in business transformation cannot be overemphasized or under-emphasized. Obviously, on one hand, you can become too rigid and attached to the process itself. On the other hand, robust processes, based on experience from a number of similar business transformations in the past, are far more useful than some skeptics envisage. After all, who would you like to be your guide for a climb – a person who can theoretically show you a path through a map of a mountain, or a person who has actually traversed that particular journey several times before, and knows all the pitfalls along the road?

Figure – The process and service component As you can see from Figure above, which shows typical processes in a supply chain 1.0, there are four levels that need to be weaved into a cohesive whole. Typically, there can be missing links between processes – vertically, or even horizontally. That means, someone working at the operational level may not know how their work is related to the work of someone at the tactical level. Even worse, for instance, a delivery scheduler may not know how his work output related to that of his next cubicle neighbor – the customer forecast expert. During a transformation, processes and services may get streamlined, re-aligned or even created from scratch to accommodate change. That is why it is pivotal to keep in mind how they all fit together by devising a visual presentation such as the pyramid diagram above. I was having a conversation with one of the senior executives responsible for business transformation in a large-sized industrial company with operations and plants across the developed world. This particular person had come from one of the top tier global consulting houses and obviously was very well versed in the hypothesis-driven problem-solving approach, which both he and I had learned in our formative years in top tier consulting houses. He was adamant that this approach would be enough to carry out a large-scale supply chain transformation in his business. Hence, he was very skeptical about the supply chain methodologies that we were espousing. In his mind, he could derive the same results from the first principles using his hypothesis-driven approach. And I was patiently explaining to him the difference between going back to the first principles to create a new approach, and deploying a tried and tested approach for supply chain transformations which had the benefit of having adapted the same hypothesis-driven approach. So I gave him an example of the early stage motorcars where people were still using solid rubber tires and a number of fittings which were a carry-over from the days of horse buggies. Of course, if he had the luxury of time and budget to make all the mistakes there were, he could probably recreate a modern-day motorcar, going through all the stages of evolution. He was smarter than most of the population, so he could perhaps complete the task in 20% of the time that it took for the actual evolution to take place and perhaps, at 20% of the budget. Yet, if a modern-day motorcar was already developed, wouldn’t he be better off testing if it suited his purpose and adapting it for his use? The role of “process” in business transformation cannot be overemphasized or under-emphasized. Obviously, on one hand, you can become too rigid and attached to the process itself. On the other hand, robust processes, based on experience from a number of similar business transformations in the past, are far more useful than some skeptics envisage. After all, who would you like to be your guide for a climb – a person who can theoretically show you a path through a map of a mountain, or a person who has actually traversed that particular journey several times before, and knows all the pitfalls along the road?  Now let us talk about the “service” bit in the process and service component. One of the remnants of last century industrial organizations which never ceases to surprise me in a modern-day organization, is the importance attached to a product in comparison to the importance attached to service by the company. What do I mean by that? Most companies still think they are selling a product, when it is clear that in today’s information economy, most companies are selling the combination of product and service. The service might be just fitting the product, or providing the right information about the product, or helping customers choose the right product for their needs. To give you an example, if you are a customer of a motorcar company like Ford or General Motors and you are looking for a particular part, you will be amazed to know how many different possibilities there are of fitting the right part for the purpose. You will then need to discuss your particular needs with someone called a Parts Interpreter in order to pick a suitable part for your motorcar. It is a very specialized job and invaluable service provided by the car industry to its customers. It is the service that makes the cost of parts more expensive than the base cost of manufacturing and selling that part. In almost every project we have done, when we calculated the overall cost-to-serve, it is very clear that the product component of the cost was supplemented by the service component of the cost, which was quite substantial to start with, and getting higher progressively. In other words, the overall cost-to-serve is made up of cost of product plus cost of service, each a fairly significant component of the overall cost-to-serve. Then why do companies keep ignoring the cost of service or treat it as a minor hassle, rather than manage it as an overall part of the full cost equation? In many companies, especially engineering-oriented companies, product takes the center stage, because it is tangible and visible, and these companies take great pride in creating superior products. Hence, service is merely an after-thought, even though the cost of service might, in many cases, be higher than the cost of product. That is the reason why a cost-to-serve analysis is an eye-opener for senior management teams or for boards of directors, when an overall cost breakdown is laid out, clearly showing that cost of product is far less than the cost of service. Suddenly, the entire orientation of the management changes towards managing the service component much more efficiently and effectively than they have ever done in the past. We have noticed that tendency in airlines, in the automotive industry, the mining industry and in many other industries. If you look at it from a customer perspective, the service is the most important part of the equation – it is well remembered long after the part (or the product) has been fitted and used. Similar to the informational component, companies are increasingly discovering their ability to cherry-pick service providers that deal with different service modules. Before this can happen, service components must be broken up into geographical, asset based and activity based components to discover and engage best service provider for each module. This is known as modularization. Then, service modules are homogenized in order to create and manage parallel interactions with several service providers at same time. The cherry-picking or commoditization of service modules enables you to configure a best-of-breed customized business-to-business network that would be impossible to emulate for your competitors, and provide flexibility, cost advantage and risk mitigation to your company. All this is possible only if you avoid making this second biggest mistake in business transformations and keep the focus firmly on the business – not on the tools – IT systems, or processes – used to achieve the business transformations. Sure you will need the right tools, and deploy them rightly – that is important. But much more important is why you are deploying them, and are you getting the right results from them?

Now let us talk about the “service” bit in the process and service component. One of the remnants of last century industrial organizations which never ceases to surprise me in a modern-day organization, is the importance attached to a product in comparison to the importance attached to service by the company. What do I mean by that? Most companies still think they are selling a product, when it is clear that in today’s information economy, most companies are selling the combination of product and service. The service might be just fitting the product, or providing the right information about the product, or helping customers choose the right product for their needs. To give you an example, if you are a customer of a motorcar company like Ford or General Motors and you are looking for a particular part, you will be amazed to know how many different possibilities there are of fitting the right part for the purpose. You will then need to discuss your particular needs with someone called a Parts Interpreter in order to pick a suitable part for your motorcar. It is a very specialized job and invaluable service provided by the car industry to its customers. It is the service that makes the cost of parts more expensive than the base cost of manufacturing and selling that part. In almost every project we have done, when we calculated the overall cost-to-serve, it is very clear that the product component of the cost was supplemented by the service component of the cost, which was quite substantial to start with, and getting higher progressively. In other words, the overall cost-to-serve is made up of cost of product plus cost of service, each a fairly significant component of the overall cost-to-serve. Then why do companies keep ignoring the cost of service or treat it as a minor hassle, rather than manage it as an overall part of the full cost equation? In many companies, especially engineering-oriented companies, product takes the center stage, because it is tangible and visible, and these companies take great pride in creating superior products. Hence, service is merely an after-thought, even though the cost of service might, in many cases, be higher than the cost of product. That is the reason why a cost-to-serve analysis is an eye-opener for senior management teams or for boards of directors, when an overall cost breakdown is laid out, clearly showing that cost of product is far less than the cost of service. Suddenly, the entire orientation of the management changes towards managing the service component much more efficiently and effectively than they have ever done in the past. We have noticed that tendency in airlines, in the automotive industry, the mining industry and in many other industries. If you look at it from a customer perspective, the service is the most important part of the equation – it is well remembered long after the part (or the product) has been fitted and used. Similar to the informational component, companies are increasingly discovering their ability to cherry-pick service providers that deal with different service modules. Before this can happen, service components must be broken up into geographical, asset based and activity based components to discover and engage best service provider for each module. This is known as modularization. Then, service modules are homogenized in order to create and manage parallel interactions with several service providers at same time. The cherry-picking or commoditization of service modules enables you to configure a best-of-breed customized business-to-business network that would be impossible to emulate for your competitors, and provide flexibility, cost advantage and risk mitigation to your company. All this is possible only if you avoid making this second biggest mistake in business transformations and keep the focus firmly on the business – not on the tools – IT systems, or processes – used to achieve the business transformations. Sure you will need the right tools, and deploy them rightly – that is important. But much more important is why you are deploying them, and are you getting the right results from them?