Lahandi Baskoro's Blog, page 20

July 18, 2019

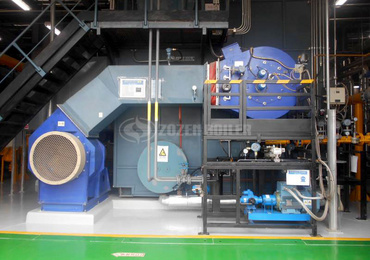

ZoZen boiler smart manufacturing

Under the strong advocacy of the country, “green sustainable development” has become the main direction of the development of major enterprises. In the practice of intelligent manufacturing, the full implementation of green manufacturing has already become the top priority of Zhongzheng boiler development. Zhongzheng Boiler practices the green manufacturing concept and strives to build the enterprise into a model for the transformation and upgrading of traditional manufacturing.

The practice of the green manufacturing concept is inseparable from the support of technology. In terms of scientific research, Zhongzheng Boiler has increased the research and development of advanced energy-saving and environmental protection technologies, and established close school-enterprise cooperation relations with universities and research institutes such as Xi’an Jiaotong University, Shanghai Jiaotong University and Beijing Zhiguang Boiler Research Institute to accelerate the green transformation of manufacturing industry. Upgrade and strive to build a green manufacturing system that is efficient, clean, low-carbon, and cyclic.

In the process of rapid development, Zhongzheng Boiler gradually reduced the energy consumption of production by continuously introducing new technologies and equipment. The numerical control rate of the cutting part reached more than 90%, combined with the cutting management system of Zhongzheng Boiler, effectively improving the material utilization rate. The economic benefits are better. In the words of the person in charge of Zhongzheng Boiler: “When the waste recycling person encounters the Zhongzheng boiler, it will cause headaches. After the steel plate is recycled, the small parts can be processed. The scrap steel of the Zhongzheng boiler can only be recycled.”

Not only that, Zhongzheng Boiler also utilizes the horizontal connection of information system in the production management of the Internet of Things, which enables product development, production, sales, logistics, and service interconnection, real-time adjustment of production status, reduction of unnecessary waste of production materials, and comprehensive realization of green production. .

In the future, Zhongzheng Boiler will continue to promote green manufacturing and intelligent manufacturing, promote high-quality development, strive to become a leading enterprise in industrial boiler manufacturing, provide products and services to more consumers, and make “Zhongzheng” brand become recognized worldwide. Famous boiler brand.

ZOZEN Boiler green manufacturing

Under the swiftness of Industry 4.0 and “Made in China 2025”, China’s manufacturing industry has stood at the fork in the road that has been eliminated or upgraded. Zhongzheng Boiler is a professional boiler manufacturer with more than 30 years of history. The chairman and management team are far-sighted and independent. R & D, joint development, intelligent manufacturing and green manufacturing simultaneously, while continuously achieving their own high-quality development, leading the traditional manufacturing industry to continue to transform and upgrade to the direction of intelligence and green development.

Zhongzheng Boiler Strategy Prospects Build Intelligent Manufacturing System

Intelligent manufacturing is the trend of the times. As a traditional enterprise, Zhongzheng Boiler has obtained dozens of automated manufacturing equipments with national patents through independent research and development and joint development. It has been jointly developed by software companies and tailored to their own digital and information management. System, innovation has established a full-process digital management system from contract management, raw material procurement, warehouse storage, digital workshop to sales terminal.

In the Zhongzheng boiler blanking workshop, all steel plates, steel pipes and other components are given unique electronic codes, which always run through the entire production, equipment and service links. This informatized logistics model not only shortens the distance between production and logistics supply, but also lays a good foundation for the future expansion of production lines and the application of new technologies, thereby improving the production efficiency and economic benefits of the entire upstream and downstream.

The manufacture of a boiler requires many important links such as cutting, forming, welding, flaw detection and hydraulic testing. The digital management of Zhongzheng runs through the whole process. In the steam drum production workshop, the high-speed CNC drilling machine is running efficiently according to the instructions of the control system. Thousands of holes can be accurately completed in less than 20 hours. This kind of workload requires at least one week for labor; advanced automatic welding equipment The automatic welding of the longitudinal and circumferential seams is completed under the tracking of the photoelectric system, which not only improves the efficiency but also ensures the welding quality. The welder can complete the operation before the screen, and is far away from the pollution of the smoke and the damage of the strong light to the eyes, realizing the green. produce.

The intelligent manufacturing system of Zhongzheng boiler standardization, specialization and digitization can reasonably dispatch enterprise people, finances and materials, realize the seamless connection between departments and departments, enterprises and markets, fully dispatch enterprise resources, and greatly shorten the boiler production cycle.

Boiler for the dairy industry

background: #ffbe00;

}

Boiler for the dairy industry

Assuming: A dairy plant produces 350,000 tons of milk products annually, and ZOZEN boiler designed 1 set of 20 tons of WNS 20-1.25-Q and 1 set of 15 tons of WNS 15-1.25-Q steam boilers to provide steam in production line. This program has high efficiency, low operating cost and fully meets customer’s steam demand

The production process of liquid dairy products mainly includes: raw milk acceptance, milk cleaning, refrigeration, preheating, homogenization sterilization, cooling, aseptic filling, fermentation, final product storage etc. Steam boiler is used for fermentation, disinfection, drying, etc., The sterilization of liquid dairy products and the fermentation process of sour milk are the main uses of the boilers in dairy plants. According to the experience from working with many dairy companies in the past, fermentation, disinfection and sterilization of dairy products is the main steam consumption sections. If heating and bathing heat are added, steam demand will be higher.

Chat online

Boiler for the pharmaceutical industry

background: #ffbe00;

}

Boiler for the pharmaceutical industry

The water heating boiler provided by ZOZEN can heat 10,000 square meters with 0.7MW boiler which runs efficiently and saving a lot of fuel costs for users.

Centralized heating is a heating method refers to the construction of a centralized heat source in industrial production areas and areas where urban residents gather and provides heat to enterprises and residents in this area. Common centralized heating modes include co-generation, regional coal-fired boilers, and gas boilers. The working principle of boiler heating is that water enters the boiler, after heating then s sent to the indoor radiator through the circulating water pump and provide heat by radiator. The water is returned to the inside of the boiler for heating, and then flows back into the radiator and circulates like that.

Chat online

Boiler for the rubber industry

background: #ffbe00;

}

Boiler for the rubber industry

ZOZEN has served many rubber product plants in the world and has rich experience for rubber industry, there is huge but uneven, high quality steam consumption which makes big difficulty for economical running of the boiler. Fuel consumption, boiler heating lost must be reduced as much as possible to economically run the boiler in rubber plants.

As the fast developing of chemical industry, there are many kinds of rubber product with similar producing process, mainly including: raw material preparing, Plastic refining, mixing, calendering, forming, vulcanizing etc., and most of these sections needs steam. Besides, some high temperature machines such as pressing, kneading, banbury machines, vulcanization molding, injection molding machine, cement mixer, conveyor belt dryer and molds heating and insulation also need thermal fluid heater.

Chat online

Boiler for the chemical industry

background: #ffbe00;

}

Boiler for the chemical industry

ZOZEN boiler can provide a complete boiler solution for the chemical industry. It will comprehensively consider the fuel cost and operating cost of the chemical industry to provide efficient and energy-saving boilers for chemical industry. Boilers in the chemical industry should choose a large furnace size to guarantee the complete combustion and wide adaption of the fuel; boiler has high level of automation, start and stop, load regulation and water supply are all automatically proceeded as per user’s need.

The chemical industry process mainly includes three steps: Raw material processing, chemical reaction, and product refining. Among them, the chemical reaction is a key step, and the reaction is carried out under conditions of a certain temperature and pressure, and a large amount of heat sources of different qualities are needed to supply heat in sections such as polymerization, condensation, drying, melting, and molding. Therefore, steam boilers and thermal fluid heaters are important equipment for chemical production.

Chat online

Boiler for the paper industry

background: #ffbe00;

}

Boiler for the paper industry

According to the specific conditions of the paper industry, ZOZEN boiler provides boilers with high combustion efficiency and low operating cost and is recognized by papermaking enterprises. The advanced boiler automatic controller, man-machine interface, users only need to set easily, the boiler can start and stop, regulate load and according to user requirements, load regulation, automatic water supply and other fully automatic operation.

The main processes of the paper industry are: pulping, pressing, drying, calendering, winding, rewinding, warehousing, etc. The pulping methods mainly include mechanical pulping, chemical pulping, semi-chemical pulping and bio-pulping. In the paper production, the heating and dissolving, machine shaping, Black slurry concentration and Squeeze drying of the chemicals in the pulping process all require heat sources, so the boiler is the main driving force for the production of the paper mill. The boiler uses coal or other fuels to generate high-temperature heat sources through conversion energy, and we transport the heat sources to various workshops for steaming and drying purposes. Because the production process consumes more energy in the production process of the paper mill, the energy cost can account for 10%-14% of the production cost. Therefore, energy conservation and consumption reduction has become one of the main ways for papermaking enterprises to increase production and save energy, improve economic efficiency and enhance competition in the product market.

Chat online

Boiler for the wine industry

background: #ffbe00;

}

Boiler for the wine industry

Through the analysis of the brewing industry, ZOZEN provides the best solution for the fermentation industry, with better energy saving and emission reduction and better fuel adaptability.

Fermentation and distillation are the two major uses of wine plants boilers. In the wine making process, fermentation is to ferment a mixture of yeast and grain to produce alcohol; distillation requires the use of a distiller, a condenser, etc. to extract the alcohol in the grain. These processes require a large amount of steam, so steam boilers are inevitably used. The stability and quality of steam produced by the boiler play a decisive role in the purity and yield of the wine. Some wineries use coal-fired steam boilers with lower fuel costs as their first choice. With the increasing awareness of environmental protection, some places restrict the use of small coal stoves, and gas and biomass boilers are favored by wineries because of their low cost and low pollution.

Chat online

November 22, 2015

Saat Euforia Go-Jek Berakhir

“Penghasilan Driver Go-Jek Capai Rp11 Juta per Bulan”, begitu headline salah satu media yang memberitakan tentang Go-Jek.

Awal bulan lalu, Kompas.com juga memberitakan bahwa Go-Jek adalah startup Indonesia dengan pertumbuhan nomor satu.

Secara kasat mata, bagi kita yang tinggal di Jabodetabek dapat dengan mudah melihat kian banyaknya driver Go-Jek dengan ciri khas helm hijaunya yang berseliweran di jalan raya.

Standar pelayanan, kemudahan pemesanan, tarif promosi flat yang murah serta insentif bonus user get user membuat penduduk metropolitan berbondong mencobanya.

Penetrasi yang Agresif

Tahun lalu, Go-Jek mendapat investasi dari Northstar Group yang nilainya tidak disebutkan. Pada kuartal kedua tahun 2015 ini Go-Jek kembali mendapat pendanaan dari Sequoia Capital, yang besarannya juga dirahasiakan dari media.

Sebagai gambaran perkiraan masifnya pendanaan yang diberikan, tahun lalu online marketplace Tokopedia mendapat pendanaan dari koalisi Sequoia Capital dan SoftBank dengan nominal sebesar 100 juta dollar, yang jika dirupiahkan dengan kurs saat ini sekitar 1,4 triliun rupiah.

Bukan kebetulan, tak lama setelah mendapatkan pendanaan dari Sequoia Capital Go-Jek agresif melakukan perekrutan talenta, memberikan harga promosi yang amat menarik serta memberikan insentif baik di sisi customer maupun driveruntuk mendorong percepatan penetrasi pasar.

Di sisi customer, Go-Jek memberlakukan tarif flat yang murah meriah plus memberikan insentif 50 ribu rupiah dalam bentuk Go-Jek Credit jika mereferensikan Go-Jek kepada calon pengguna lain.

Strategi ini berhasil mendorong Go-Jek tembus angka satu juta pesanan pada awal Juli tahun ini, sekitar enam bulan setelah versi aplikasinya diluncurkan.

Di sisi driver, Go-Jek akan mensubsidi selisih biaya antara tarif flat dengan tarif yang seharusnya. Driver juga akan diberikan tambahan 50 ribu rupiah untuk setiap lima kali order yang berhasil dijalankan.

Mungkin ada insentif-insentif lainnya, namun setidaknya itulah yang saya tahu dari hasil obrolan dengan para driver Go-Jek.

Tingginya demand dan besarnya insentif ini jelas membuat banyak orang tertarik untuk bergabung menjadi driver Go-Jek.

Awal Agustus ini dikabarkan bahwa tak kurang dari 15 ribu orang yang telah menjadi driver Go-Jek. Ditambah lagi dengan open recruitment masal yang dilakukan di Senayan pasca lebaran kemarin, kemungkinan jumlah driver Go-Jek sat ini lebih dari 20 ribu orang.

Gojek-foria

Harga promosi dan insentif yang diberikan Go-Jek otomatis mendorong pertumbuhan demand disisi customer.

Ditambah lagi dengan hebohnya pemberitaan mengenai Go-Jek di media tentang besarnya pendapatan yang bisa didapatkan oleh para driver, maka ini bisa dibaca sebagai euforia masyarakat terhadap pertumbuhan layanan ini, istilah saya: Gojekforia.

Ojek on demand dengan harga yang amat murah adalah solusi praktis untuk menjawab kebutuhan warga Jabodetabek dan kota besar lainnya untuk gesit menembus kemacetan kota. Sebuah solusi yang belum bisa diberikan oleh transportasi publik kita.

Namun sampai kapan pihak Go-Jek harus senantiasa boncos membiayai strategi user acquisition dengan model seperti ini? Belum lagi ditambah biaya operasional Go-Jek yang diantaranya memberikan masker dan shower cap bagi customernya serta helm dan jaket bagi driver.

Rencana menuju harga yang rasional sudah disampaikan sang CEO, Nadiem Makarim pada awal Agustus ini di salah satu media. Beliau mengutarakan hal yang masih menahan Go-Jek untuk menuju harga normal adalah sang kompetitor utama, GrabBike yang masih memberikan harga promosi.

Artinya saat GrabBike berhenti memberikan tarif promosi, maka tinggal tunggu waktu pihak Go-Jek akan menutup keran insentifnya.

Minggu lalu, Go-Jek sudah mulai menaikkan tarif promosi yang tadinya 10 ribu rupiah sekarang menjadi 15 ribu rupiah. Sinyal-sinyal layanan ojek on demand ini untuk menuju harga normal sudah mulai terlihat.

Prediksi saya, jika tarif menjadi normal, maka demand Go-Jek lebih kecil dari sekarang, dari yang tadinya mass market menjadi segmen kelas menengah yang non price-sensitive dan membutuhkan kenyamanan serta kecepatan untuk mencapai tujuan.

Kesetiaan & Tarif Promosi

Sesaat setelah tarif flat Go-Jek naik ke 15 ribu rupiah, saya menanyakan kepada sang driver berapa harga yang seharusnya saya bayarkan untuk rute yang baru saja saya jalani, yaitu Stasiun Pondok Cina sampai Cimanggis, Depok.

Sang driver menunjukkan di layar ponselnya besaran tarif normalnya adalah 41 ribu rupiah dengan rincian dibayar oleh saya 15 ribu rupiah, dan disubsidi oleh Go-Jek dikirim langsung ke rekeningnya sebesar 17.800 rupiah, sisanya merupakan bagian yang diambil Go-Jek.

Biaya 15 ribu rupiah untuk rute Cimanggis – Pondok Cina jelas harga yang menarik bagi saya, namun harga 41 ribu rupiah untuk layanan ojek akan membuat saya berpikir lagi untuk menggunakan Go-Jek secara harian.

Bahkan harga ini kalah bersaing dengan langganan ojek pangkalan disini yang memberikan harga di kisaran 30 ribuan untuk rute yang sama.

Selama tarif promosi ini saya masih setia menggunakan Go-Jek.

Yang menarik untuk dilihat adalah fenomena para manajer dan karyawan lainnya yang kemarin meninggalkan kerja kantoran untuk beralih profesi menjadi full-time driver Go-Jek.

Apakah mereka akan tetap setia menjadi driver Go-Jek saat harga promo berakhir dan demand Go-Jek menuju titik keseimbangan baru? ■

—

Tulisan ini juga muncul di Nextren.com (salah satu lini media grup Kompas Gramedia).

August 20, 2015

Review ASUS Zenpower

Sekitar sebulan yang lalu saya dikirimi ASUS Zenpower 10050 mAh oleh ASUS Indonesia. Setelah saya coba pergunakan selama beberapa waktu untuk keperluan charging Motorola Moto-G dan LG Leon, berikut sekilas review dari saya.

Design

ASUS Zenpower datang dengan kemasan yang compact, maklum ASUS mengklaim produk ini ukurannya sebesar kartu kredit. Setelah saya ukur, ASUS Zenpower ini memang lebar dan panjangnya mirip sebesar kartu-kartu kita yang ada di dompet, namun sedikit lebih besar sekitar 5 mm.

Selain itu yang saya sukai adalah material bahan almunium dan finishing yang digunakan untuk membalut produk ini memberikan kesan kokoh, elegan dan berkelas, jauh dari kesan murahan. Edisi warna gold yang saya dapatkan menambah lagi impresi mewah yang ditampilkan.

Untuk ergonomi, ASUS Zenpower ini nyaman dipegang sekalipun sembari sedang melakukan charging bersama handphone. Karena ada produk power bank dengan bentuk fisik batangan (hampir silindris) atau bentuk yang terlalu lebar, sehingga tidak nyaman untuk digenggam jika sedang digunakan sembari charging dengan handphone.

Kelengkapan lainnya, ASUS Zenpower ini memiliki satu tombol power, empat titik lampu indikator satu socket USB dan satu socket mini USB.

Satu kelemahan minor dari sisi desainnya adalah lokasi socket USB dan mini USB yang berdekatan. Hal ini cenderung akan menyulitkan jika ingin melakukan charging power bank jika masih membiarkan kabel bawaan dalam posisi tercolok.

Performance

Untuk pengukuran performance tidak saya uji secara mendetail dan akurat, namun kira-kira butuh sekitar 12 jam untuk mengisi ASUS Zenpower dari kondisi kosong hingga penuh. Menariknya, saya merasa ASUS Zenpower ini bisa lebih cepat melakukan charge sekitar 20-30% daripada charging dengan charger bawaan handphone.

Power bank ini akan berhenti charging saat di-charge jika dayanya sudah terisi penuh. Saat melakukan charge untuk handphone, ASUS Zenpower juga tidak terasa panas.

Fungsi tombol power-nya adalah hanya untuk mengetahui jumlah ketersediaan cadangan daya yang tersimpan dalam power bank, karena ASUS Zenpower ini otomatis menyala dan mengisi daya begitu ada handphone yang dicolokkan.

So?

ASUS Zenpower 10050 mAh menjadi pilihan untuk yang membutuhkan power bank yang praktis dibawa, nyaman digenggam, desain berkelas, aman, punya daya simpan yang besar dan berasal dari brand yang sudah punya reputasi.

Namun jika lebih memprioritaskan kebutuhan power bank dengan output socket yang banyak, maka ASUS Zenpower 10050 mAh ini mungkin bukan power bank yang tepat.

Foto utama diambil dari B & H.

Lahandi Baskoro's Blog