More on this book

Community

Kindle Notes & Highlights

Read between

December 28 - December 31, 2019

more than two hundred iPhones per hour—over three a minute.

That is a herculean feat of manufacturing. Foxconn is now the world’s biggest electronics-contracting company and the third-biggest technology company by revenue—its annual take is $131.8 billion—thanks largely to its iPhone orders.

it’s the ability to tackle that complexity with ruthless efficiency that makes Foxconn and its competitors so enticing to American companies like Apple.

Obama interrupted. He wanted to know what it would take to bring that work home.

“Those jobs aren’t coming back,” Jobs famously said.

It wasn’t just that overseas labor was cheaper...

This highlight has been truncated due to consecutive passage length restrictions.

it was also that the sheer size, industriousness, and flexibility of the workforce there was necessary to me...

This highlight has been truncated due to consecutive passage length restrictions.

the real reason that Apple kept its operation overseas wasn’t the cheap labor; some analysts estimated that building the phones in the U.S. would raise labor costs by only ten dollars a phone.

No, they stayed there because of the immense, skilled workforce and the interlocking ecosystem of affiliated industry that had grown in Shenzhen.

Droves of workers could be summoned to quickly assemble a new prototype for testing or swiftly make laborious adjustments to a huge number of products that were about to be shipped. Parts could be r...

This highlight has been truncated due to consecutive passage length restrictions.

If Apple had to make a last-minute change to the iPhone—say, an alteration in the aluminum casing, or a new cut for the touchscreen—in a heartbeat, Foxconn could summon thousands of workers a...

This highlight has been truncated due to consecutive passage length restrictions.

“The speed and flexibility is breathtaking,” the executive said. “There’s no American plant that can match that.”

The follow-up question here might be: Why is it so imperative that our phones be assembled with “breathtaking” speed?

The cost is tens of thousands of lives being made miserable by those last-minute orders, militaristic work environments, and relentless stretches of overtime.

This is not necessarily Apple’s fault, but it is certainly a by-product of a globalized workforce.

And Tim Cook, who rose through the ranks at Apple on the strength of his supply-chain wizardry, is himself a key driver in that push toward breakneck production.

One of his initiatives has been an attempt to eliminate inventory—today, Apple turns over its entire inventory every five days,

Since the explosion in the iPhone’s popularity—and the rise of the iPad and competitor smartphones and tablets—Foxconn has branched out and set up a number of factories across China.

Almost everyone we spoke with really liked the iPhone.

They just couldn’t afford it.

We didn’t meet a single iPhone assembler who actually owned the product he or she made hundreds of each day.

here we are, passing the hull of another building housing another operation piecing together another gadget.

It’s just so big.

This isn’t all Apple, of course; Foxconn helps manufacture Samsung phones, Sony PlayStations, and device...

This highlight has been truncated due to consecutive passage length restrictions.

Longhua starts to feel like the dull middle of a dystopian novel, where the dread sustains but the plot doesn’t,

Hundreds of thousands of people and it never gets louder than the decibel of polite conversation.

There were a number of things that would surely violate U.S. OSHA code—unprotected construction workers, open chemical spillage, decaying, rusted structures, and so on—but

but there are probably a lot of things at U.S. factories that would violate OSHA code too.

For whatever reason—the rules imposing silence on the factory floors, its pervasive reputation for tragedy, or the general feeling of unpleasantness the environment itself imparts—Longhua

Longhua felt heavy, even oppressively subdued.

Besides the restaurants and the cybercafés—both, notably, places where workers have...

This highlight has been truncated due to consecutive passage length restrictions.

there was no place designed in the interests of public well-being, or even designed to ...

This highlight has been truncated due to consecutive passage length restrictions.

What was remarkable about Foxconn City was that the whole of its considerable expanse was unrepentantly dedicat...

This highlight has been truncated due to consecutive passage length restrictions.

You were either working, paying, or shuffling gr...

This highlight has been truncated due to consecutive passage length restrictions.

Since the suicide epidemic began, Apple has made some public efforts to hold its suppliers more accountable for workplace conditions.

Suicides have slowed, but not stopped. Workers are still logging too much overtime, but child labor has decreased. Wages seem to have stagnated, and turnover is still high.

Laborers are slowly becoming better organized, and wildcat strikes are becoming more common. A generation of poorly treated workers is apt to transfer its knowledge to the next, and as with protests against pollution, the predilection for popular resistance is growing.

There are still few meaningful worker protections—so-called labor unions have long existed, but their leadership is appointed by the state, and their power is nil—but many workers have seen the power of collective action.

Advocacy groups like CLM, SACOM, and the China Labor Bulletin have succeeded in pushing the issue of workers’ righ...

This highlight has been truncated due to consecutive passage length restrictions.

Meanwhile, the bulging middle class is becoming less tolerant of poor condi...

This highlight has been truncated due to consecutive passage length restrictions.

But the quality of life for the workers—the ferocious pace, the semi-mandatory long hours—has remained the same for years.

These precedents are doubly important because Apple and iPhone manufacturing contracts have such a massive influence on the industry—and on working conditions at large.

“I had a meeting with Samsung executives and they said they would...

This highlight has been truncated due to consecutive passage length restrictions.

They had done it. They’d closed the loop.

They’d made an app for driving the workers that make the devices that enabled apps.

Now, factory workers could be controlled, literally, by the devices they were manufacturing.

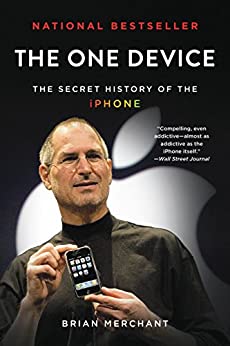

Product launches are a pillar of Apple’s mythology/marketing machine.

Steve Jobs introduced every major Apple product since the Mac from a stage like this one.

Jobs was a master salesman.